Overview

SIMATIC TP170B Touch Screen (Model 6AV6545-0BB15-2AX0) Product Data Sheet, introducing the technical parameters and functional features of this 5.7-inch monochrome STN touch screen: using a 32-bit RISC 66MHz processor, equipped with 768KB user data available memory and 1 CF card slot, supporting multiple communication interfaces such as MPI/PROFIBUS DP (up to 12Mbit/s), front-end protection level IP65, back-end IP20, working temperature 0-50 ℃ (vertical installation); It can be configured through ProTool/Lite V5.2 SP1+or WinCC flexible Compact 2004+, supporting 1000 variables, 100 process screens, 1000 alarm messages, and 100 formulas. It is compatible with multiple brands of controllers such as S7-200/300/400 and TI 505, and is suitable for process monitoring and operation control in industrial automation scenarios.

Hardware core parameters

1. Display and operation unit

Category parameter details

Display screen size 5.7 inches

Display type STN (Super Twisted Column) screen, 4 levels of blue monochrome (Blue levels)

Resolution 320 × 240 pixels (W × H)

Backlight lifespan of approximately 50000 hours (at 25 ℃ environment)

Operation mode: Control element simulation resistive touch screen (touch only operation, no physical buttons)

Input supports numeric input, alphabetical input, hexadecimal input, and does not support simultaneous operation with multiple keys

External device without external mouse/keyboard/barcode reader interface

2. Processor and Memory

Category parameter details

Processor type: 32-bit RISC processor

Main frequency 66MHz

Memory type: Flash memory+RAM

User data available memory 768KB

Expand storage with 1 CF card slot (supports CF card expansion, without SD/USB/hard disk/optical drive)

3. Power supply and power consumption

Category parameter details

Power input voltage type DC (direct current)

Allowable range+18V~+30V DC

Rated voltage 24V DC

Current and power consumption rated current 0.25A

Power consumption 6W

Compatibility between communication interface and controller

1. Communication interface

Number of interface types, key parameter usage

RS232 2- Connect printers, programming devices, etc

RS422 1- Serial Communication

RS485 with a maximum transmission rate of 12Mbit/s supports MPI/PROFIBUS DP protocol and is connected to the controller

TTY 1 optional configuration with additional serial communication extension

1 CF card slot – data storage, configuration backup

2. Controller compatibility

Supports multiple brands of controllers, including Siemens and mainstream third-party models, as follows:

Brand/Series Model/Protocol Communication Method

Siemens S5 serial PROFIBUS DP

Siemens S7-200 PPI (point-to-point) MPI、PROFIBUS DP

Siemens S7-300/400 MPI, PROFIBUS DP (does not support PROFINET)

Siemens TI 505 point-to-point, network

Siemens Win AC/SUNMERIK/SMOTION adaptation corresponding protocol

Allen Bradley DF1 point-to-point, network (does not support DH485)

Mitsubishi FX/MP4 point-to-point (network not supported)

Telemecanique ADJUST/Uni Track Point to Point, Network

Modicon Modbus point-to-point, network

GE Fanuc SNP point-to-point, network

Software configuration and functional features

1. Configuration tool

Configuration tool version requirements type core usage

ProTool/Lite V5.2 SP1 and above basic configuration tool screen, variable, alarm and other basic function configurations

WinCC flexible Compact 2004 and above advanced configuration tools support task planning and more graphic elements, which need to be ordered separately

2. Core functional parameters

(1) Variable and Image Management

Function category parameter value remarks

The total number of variable management is 1000, including 1000 date and time type variables and 1000 internal variables each

Initial value quantity of 1000 supports variable limit setting and multiplexing

Screen management process with 100 screens supporting PLC selection and configurable startup screens

Each screen contains 50 variables and 2000 text elements, with 100 visible switches per screen

(2) Alarm and Formula Management

Function category parameter value remarks

1000 alarm management operations/fault messages each, supporting 8 process values/messages and 99 confirmation groups

Alarm buffer, circular buffer (n × 128), no sound feedback, supports first/last value display

Formula management: 100 formulas with 32KB integrated Flash storage, expandable

Each formula has 200 data records, with each record containing 200 entries

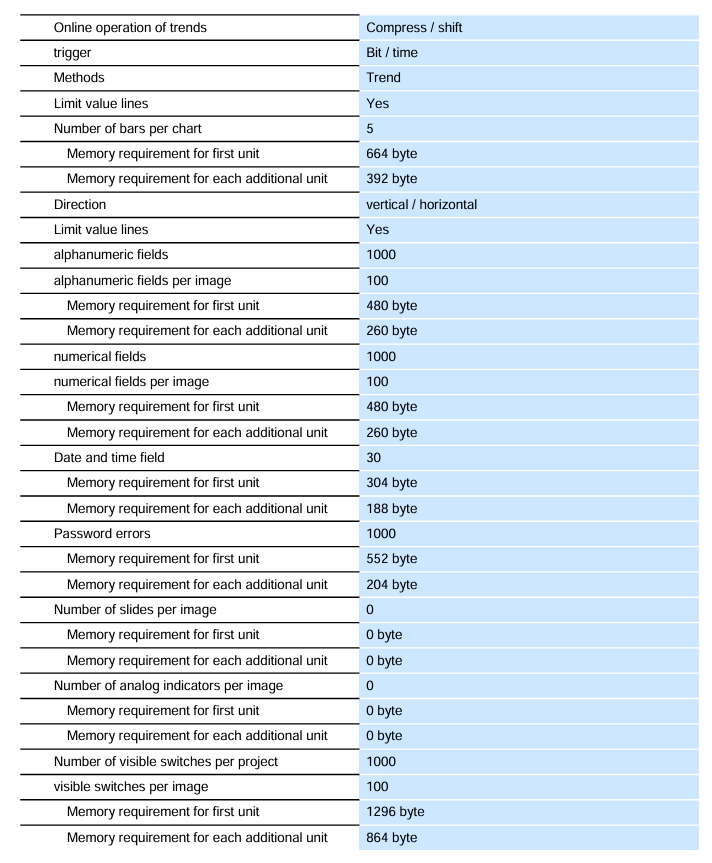

(3) Graphics and dynamic elements

Function category parameter value remarks

500 graphic element icons, including 50 full screen icons

500 dynamic objects/item, up to 5 per screen, supporting color changes, X/Y movement, and hiding

Trends and charts are plotted horizontally with 8 curves per chart, supporting limit lines

Each chart has 5 bar charts supporting vertical/horizontal directions, including limit lines

3. Safety and maintenance functions

Permission management: 9-level password protection, 10 user groups, passwords can be exported;

Maintenance tools: support touch screen calibration, configuration backup/restore, Delta transfer, device switching;

Simulation function: The configuration software supports offline simulation for easy early debugging.

Environment and installation specifications

1. Environmental parameters

Remarks on environmental category parameter values

Temperature working temperature (vertical installation) 0 ℃~+50 ℃-

Working temperature (maximum tilt angle) 0 ℃~+40 ℃ Maximum allowable tilt angle ± 35 ° (without external ventilation)

Storage/transportation temperature -20 ℃~+60 ℃-

Maximum relative humidity of 85% in non condensing environment

Front end protection level IP65 dustproof and waterproof, suitable for harsh industrial environments

Backend IP20 only prevents finger touch and needs to be installed inside the control cabinet

2. Installation and physical specifications

Specification Category Parameter Value Remarks

Installation method, installation technology, clamp terminals for easy fixation and disassembly

Front end dimensions (W × H) 212mm × 156mm-

Installation incision size (W × H) 198mm × 142mm control cabinet opening size

Equipment depth 45mm-

Weight Net weight 0.7kg Lightweight design for easy installation

certification standard

International certifications: CE certification, FM Class I Div.2 (hazardous area certification), UL certification, CSA certification;

Compliance: Complies with industrial control equipment safety and electromagnetic compatibility standards.

Leave a comment

Your email address will not be published. Required fields are marked *