Overview of Product System

The Siemens SICAM Substation Automation Solution (Edition 8.1) covers the entire lifecycle requirements of substations, from the core control platform to terminal detection equipment, forming a modular and scalable product matrix. The core is built around the IEC 61850 international standard, balancing compatibility and foresight, and adapting to scenarios such as traditional power grid upgrades and new energy grid integration.

Detailed introduction of core products

(1) SICAM 8 Power Automation Platform

As the core architecture, it integrates hardware and software solutions to support multi scenario automation requirements.

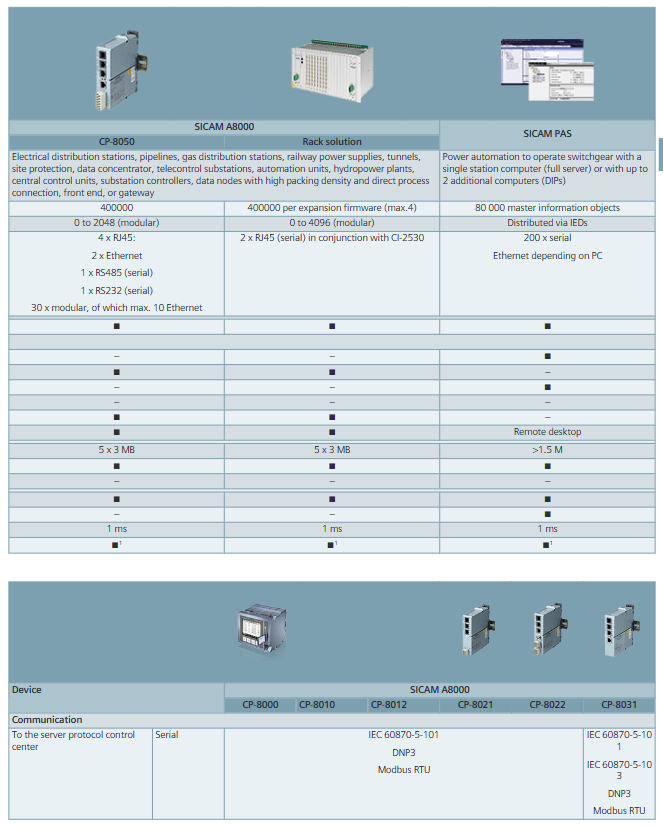

Applicable scenarios for key characteristics of core components

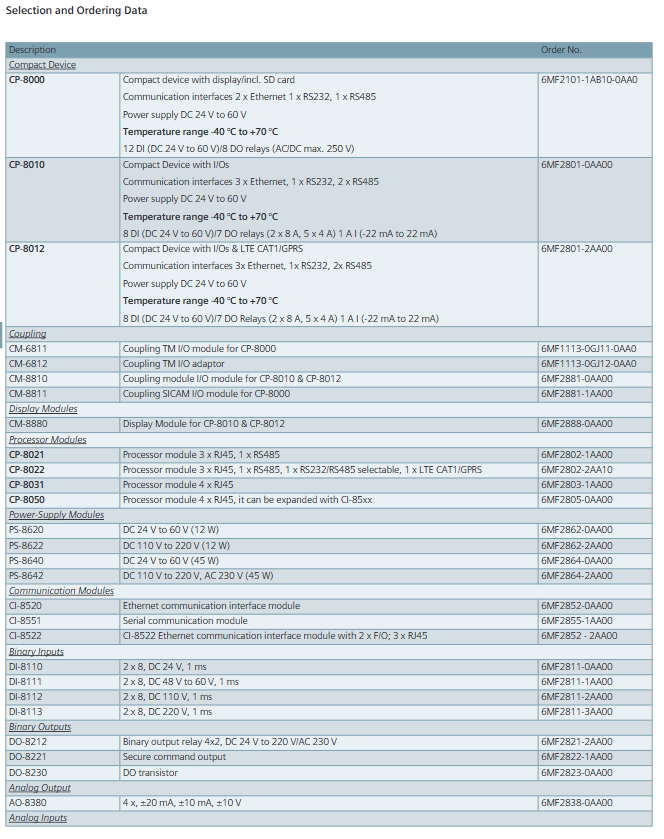

SICAM A8000 series modular design, supporting 18V~286V wide voltage power supply; -Operating temperature of 40 ° C~+70 ° C; Up to 2048 I/O points for power transmission and distribution, railway power supply, tunnel monitoring

SICAM S8000 is hardware independent and supports virtualization deployment; Compatible with Linux systems such as Debian/Red Hat; Can integrate 1200 IED devices virtual SCADA front-end, offshore wind power

SICAM HMI supports free authorization of 200 data points; Support HTML5 browser, suitable for local monitoring of small and medium-sized power plants on tablets

SICAM GridPass automated certificate management, supporting X.509 certificates; Compatible with IEC 62351 standard OT network security certification

(2) Control, monitoring, and evaluation tools

Focus on monitoring the operation status of the power grid and analyzing faults to ensure the reliability of power supply.

SICAM PQ Analyzer: Supports EN 50160 standard and can analyze 10+power quality parameters such as voltage sag and harmonics; Provide analysis tools such as Incident Explorer and PQ Inspector, with a minimum hardware requirement of Intel Core 2 Duo 1.6 GHz processor and 2GB of memory.

SIGRA: A graphical fault waveform analysis tool that supports COMTRADE format; Compatible with systems such as Windows 10/Server 2019; Provide a 30 day free trial version.

(3) Engineering, diagnostic, and testing tools

Covering the entire process of project configuration, equipment debugging, and system maintenance.

Tool Name Core Function Key Parameters

SICAM SCC SCADA system, supporting multi client deployment; Compatible with SIMATIC WinCC up to 65536 data points

SICAM PAS power automation system, supporting redundant configuration; Support OPC DA/XML DA protocol for up to 800 interval devices to access

DIGSI 5 SIPROTEC 5 equipment engineering tool, available in Compact/Standard/Premium versions, supports up to unlimited SIPROTEC devices (Premium version)

IEC 61850 System Configurator Cross vendor IEC 61850 device configuration, supports SCL file import and export, supports IEC 61850 Ed1/2.0/2.1 versions

(4) Interval Controller (SIPROTEC 6MD Series)

Specialized control equipment for different voltage levels and scenarios.

6MD84: IO Box design, supporting 19-45 binary I/O points; Adapt to the process bus system and support PRP redundant communication.

6MD85/86: Universal interval controller, supporting 8-75 I/O points; 6MD86 has added circuit breaker failure protection and synchronous phasor measurement (PMU) function.

6MD89: Railway specific, compatible with 16.7Hz frequency; Supports 1-2 phase measurement and is suitable for contact network power supply systems.

(5) Distribution system automation

Optimize the reliability and efficiency of the distribution network, and support the integration of distributed energy sources.

SICAM DCM: Modular fault detection and control solution, supporting 3-phase undervoltage protection and ground fault detection; Response time<20ms.

SIPROTEC 7SC80: Distribution network protection equipment, supporting a wide temperature range of -50 ° C to+85 ° C; Integrated CFC logic programming, supporting 20 custom protection functions.

(6) Short circuit indicator and communication accessories

Short circuit indicator: including SICAM FCM plus/FSI series, supports wireless communication, and is compatible with cables and overhead lines.

Power line communication: Powerlink IP and AKE 200 devices ensure stable communication between power grid equipment.

Core technical characteristics

Compatibility: Fully supports 10+industrial protocols such as IEC 61850, IEC 60870-5-101/104, DNP3, etc., and is compatible with devices from multiple vendors.

Security: Compliant with BDEW white paper, NERC CIP, IEC 62351 and other standards, with TLS encryption, Role Access Control (RBAC), firmware signing and other functions.

Scalability: Modular design supports hardware expansion (such as SICAM A8000, which can expand 16 I/O expansion lines), and software supports function point authorization upgrades.

Environmental adaptation: The working temperature of the core equipment covers -40 ° C~+70 ° C, and some products support IP40 protection level, suitable for harsh industrial environments.

Typical application scenarios

Transmission and distribution substations: interval control, power quality monitoring, rapid fault isolation.

New energy grid connection: monitoring and scheduling of photovoltaic/wind power plants, supporting microgrid control.

Railway power supply: 16.7Hz frequency adaptation, contact network power supply monitoring and protection.

Industrial power distribution: dynamic load management, peak reduction, ensuring stable industrial power supply.

Leave a comment

Your email address will not be published. Required fields are marked *