1、 Product Overview

Bosch Rexroth HNC100-3X is a programmable motion controller for electro-hydraulic drive systems, optimized and developed based on the experience of thousands of hydraulic application projects. It focuses on hardware and software scalability, open system architecture, and hydraulic adaptive control algorithms, and can achieve high-precision control of 1-4 hydraulic axes, widely applicable to various industrial scenarios.

2、 Core advantages

Bidirectional scalability feature

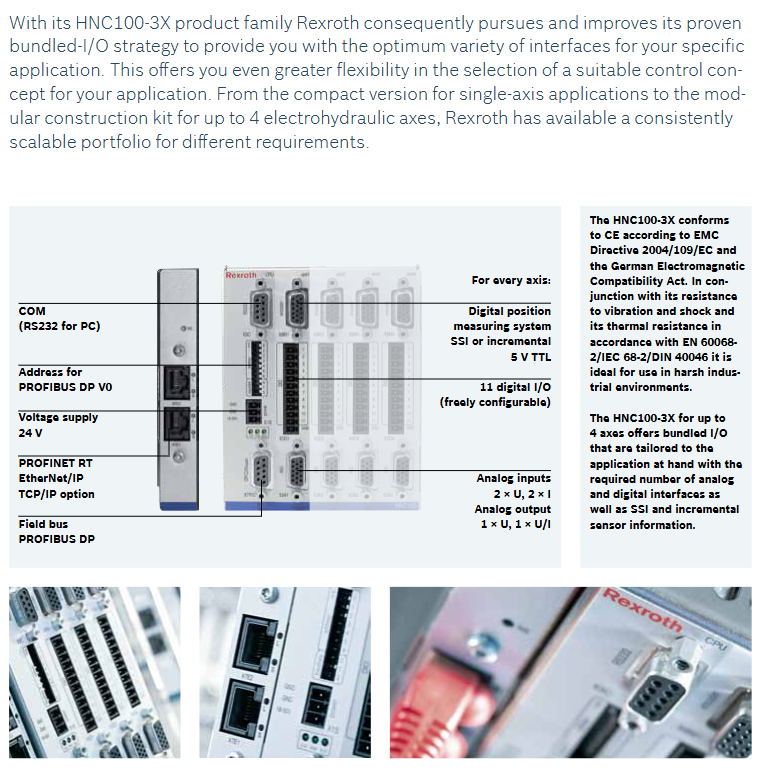

Hardware Expansion: Covering compact single axis version to 4-axis modular version, the size increases with the number of axes, and the number of interfaces expands synchronously.

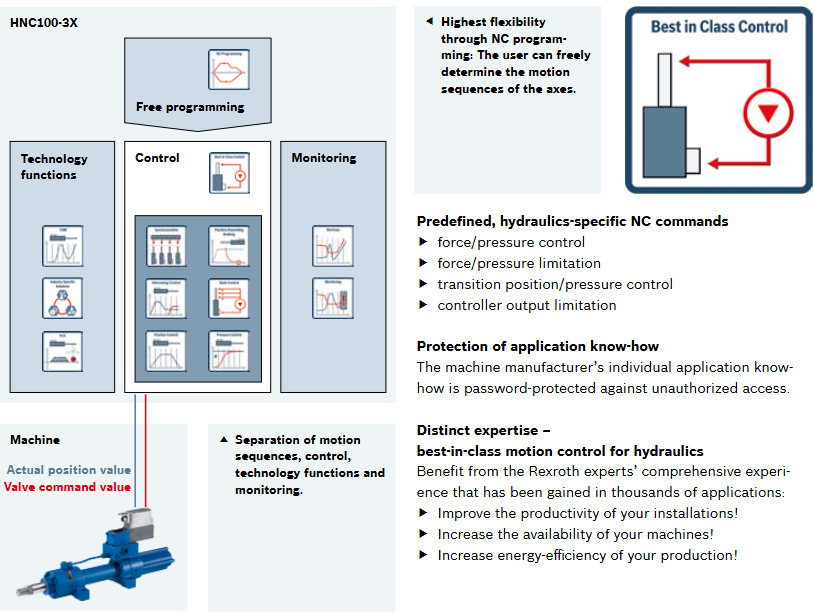

Software extension: Controller functions can be activated as needed, integrating control modules such as position, pressure, force, and synchronization without the need for additional hardware.

Open system architecture

Communication openness: Supports mainstream bus protocols such as PROFIBUS DP, PROFINET, EtherNet/IP, TCP/IP, and seamlessly integrates with existing automation architectures.

Programming openness: Supports DIN 66025 standard NC programming, allows free configuration of motion sequences, and supports open access to controller parameters.

Hydraulic exclusive optimization

Integrate commonly used hydraulic functions such as position pressure/force alternating control and synchronous control, adapting to the power density and robustness characteristics of hydraulic systems.

The control cycle is as low as 0.5ms/axis, greatly improving the response performance of the controller.

3、 Hardware specification details

Specifications: Compact version (single axis), 1 axis version, 2 axis version, 3 axis version, 4 axis version

Dimensions (height × depth × width) 120 × 108 × 34mm 120 × 124 × 48mm 120 × 124 × 65mm 120 × 124 × 82mm 120 × 124 × 99mm

Analog input 3 channels (1U+2I) 4 channels 8 channels (4U+4I) 12 channels (6U+6I) 16 channels (8U+8I)

Analog output 2 channels (2U) 2 channels (1U+1U/I) 4 channels (2U+2U) 5 channels (3U+2U) 6 channels (4U+2U)

Digital I/O 8, 11, 22 (maximum 20 outputs) 33 (maximum 20 outputs) 44 (maximum 20 outputs)

Bus Communication PROFIBUS DP PROFIBUS DP+PROFINET+EtherNet/IP Same 1 Axis Version Same 1 Axis Version Same 1 Axis Version Same 1 Axis Version

Basic hardware parameters: power supply voltage of 18-30VDC, working temperature of 0-50 ℃, in compliance with CE, EN 60068-2 and other standards, anti vibration and anti impact, suitable for harsh industrial environments.

Encoder support: SSI or incremental encoder interfaces are standard on each axis to meet high-precision position detection requirements.

4、 Software and Debugging Tools

Core control function

Position control: supports characteristic curve adjustment and fine positioning; Pressure/Force Control: Integrated PIDT1 controller and differential pressure evaluation.

Synchronous control: adapted to the synchronous coordination of multiple hydraulic shafts; Alternating control: Automatically achieve position pressure/force mode switching.

Monitoring function: including wire breakage detection, tracking error monitoring, travel limit monitoring, etc., to ensure equipment safety.

debugging tool

WIN-PED 7: Free downloadable engineering software that supports project configuration, parameter configuration, NC programming, and provides online assistance.

WinView: Integrated into WIN-PED, supports 16 channel real-time data recording and analysis, facilitating fault diagnosis.

5、 Application Fields and Technical Support

Typical Applications

Metallurgical industry: steel rolling and drawing equipment; Rubber and plastic industry: injection molding machines, rubber vulcanizing machines.

Machine tool industry: bending machines, press machines; Special machinery: packaging equipment, assembly lines.

Technical Support

Provide hydraulic drive selection, customized training, and on-site debugging services.

The official website provides software updates, technical document downloads, and supports email technical consultation.

key issue

What are the hardware scalability aspects of HNC100-3X? Answer: Hardware scalability is reflected in two dimensions: the number of axes and interfaces. The configuration covers 1-4 axes, expanding from the compact single axis version to the 4-axis modular version; As the number of axes increases on the interface, analog I/O expands from 3 to 16, and digital I/O expands from 8 to 44. It also supports flexible selection of multiple bus protocols such as PROFIBUS and PROFINET.

What exclusive optimizations has HNC100-3X made for hydraulic systems? Answer: One is to optimize the control algorithm, integrate commonly used hydraulic functions such as position pressure/force alternating control and synchronous control, and adapt to the power characteristics of the hydraulic system; The second is performance optimization, with a control cycle as low as 0.5ms per axis to improve response speed; The third is functional adaptation, providing hydraulic exclusive NC commands, supporting DIN 66025 standard programming, simplifying the development of hydraulic application programs.

How can the debugging tools and open features of HNC100-3X reduce the total cost of ownership for users? Answer: In terms of debugging tools, the free WIN-PED 7 software supports one-stop project configuration, programming, and diagnosis. WinView’s real-time data recording function can quickly locate faults and shorten debugging and downtime; In terms of open features, it supports mainstream bus protocols and can seamlessly integrate with existing automation architectures without the need for additional hardware adaptation. At the same time, the open parameters and programming interfaces facilitate users to customize functions according to their needs, reducing secondary development costs.

Leave a comment

Your email address will not be published. Required fields are marked *