The official technical information of Rexroth’s two drive controllers (DIAX04 series HDD/HDS second-generation, EcoDrive 03 series DKC. 3-040/-100/-200) * * revolves around safety operation specifications, product identification and parameters, wiring installation requirements, maintenance and service, clearly targeting professional electrical personnel, emphasizing safety points such as high voltage protection, electrostatic protection, and dangerous motion prevention. It specifies in detail the rated voltage (such as 200-480V AC), current (such as EcoDrive 03 maximum output current of 200A), wiring specifications, installation spacing, and fault diagnosis and service support for each model, providing standardized guidance for the full life cycle use of the equipment.

1、 Basic information of the document

Covering products

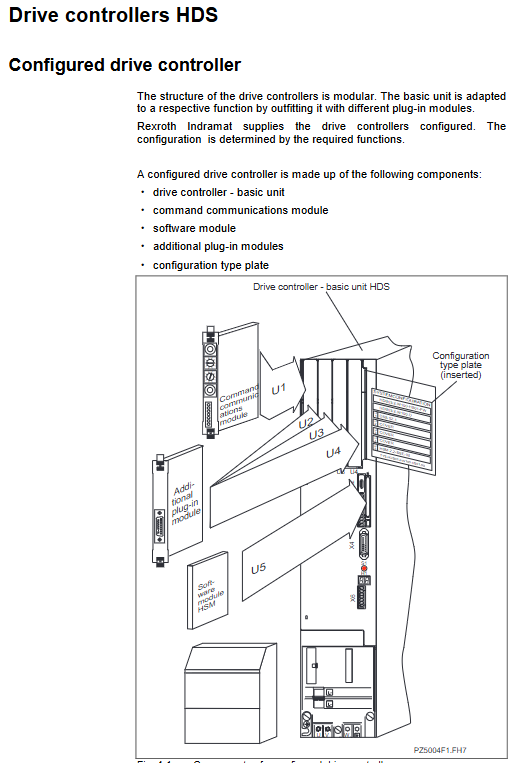

DIAX04 series: Second generation HDD/HDS drive controller, including HDD02.2-W040N-HD32, HDS02.2-W040N and other models, supporting servo drive and spindle drive functions.

EcoDrive 03 series: DKC * *. 3-040/-100/-200 drive controller, suitable for scenarios such as machine tools and automation equipment.

Document type and purpose

DIAX04 is a project planning manual that focuses on electrical structure design, control cabinet installation, and drive component deployment.

EcoDrive 03 is an operation manual that focuses on practical guidance for installation, operation, and maintenance.

Target audience: Only electrical installation and maintenance personnel who have received professional training and qualification certification are allowed to operate.

2、 Core security requirements

(1) Electrical safety

High voltage protection

There is a risk of high voltage exceeding 50V in the equipment. After power failure, it is necessary to wait for 30 minutes (EcoDrive 03) or 5 minutes (DIAX04) for the capacitor to discharge. The measured voltage must be below 50V before operation.

The grounding conductor must use copper wire with a cross-sectional area of ≥ 10mm ² and be permanently and reliably connected, with a leakage current greater than 3.5mA.

Overcurrent and short circuit

External overcurrent protection device is required. The EcoDrive 03 branch circuit protection fuse specifications are 20A (040 model) and 70A (100/200 model).

Do not plug or unplug connectors while powered on to avoid short circuit damage to equipment.

(2) Mechanical and Sports Safety

Prevention of dangerous sports

Due to wiring errors, improper parameter settings, etc. that may cause dangerous movements, safety fences, light curtains, and emergency stop switches need to be installed (effectiveness needs to be verified before starting).

The vertical axis requires additional mechanical locking or external braking devices, and the standard motor brake does not meet personnel safety requirements.

Handling and assembly

Use appropriate tools and lifting equipment to avoid squeezing and shearing injuries, and if necessary, wear protective equipment such as goggles and safety shoes.

Do not stand under suspended loads and promptly clean up any leaking liquids to prevent slipping.

(3) Special protection

Electromagnetic and High Temperature Protection

Pacemakers and metal implant wearers are prohibited from entering the equipment operation/installation area. If they need to enter, they must consult a doctor.

After the device is running, the temperature of the casing may exceed 60 ℃. The cooling of EcoDrive 03 takes up to 140 minutes and requires wearing protective gloves or waiting for cooling before operation.

Electrostatic protection

Grounding (human body, tools) is required before contacting electronic components, and sensitive components need to be stored and transported in conductive packaging.

The signal line and power line are wired separately, and shielded wires are required for analog signals to avoid interference.

3、 Key parameters and identification of products

(1) Model code rules

Product Series Model Code Example Core Field Meaning

DIAX04-HDS HDS03.2-W100N-HS01-FW W=air-cooled, 100=rated current 100A, HS=SERCOS interface

EcoDrive 03 DKC03.3-200-7-FW 03=series version, 200=maximum output current 200A, FW=firmware (to be ordered separately)

(2) Comparison of core rated parameters

Parameter unit DIAX04 (HDS03.2-W100N) EcoDrive 03 (DKC03.3-200)

Rated input voltage V 200-480 AC 200-480 AC

Maximum output current A 100 200

Maximum output frequency Hz -1000

Equipment weight kg 11 19.5

Power loss W 280 960

Working environment temperature ℃ 5-45 (rated), maximum 55 (rated), maximum 55 (rated), maximum 55 (rated)

4、 Installation and wiring specifications

(1) Wiring requirements

Key interface definition

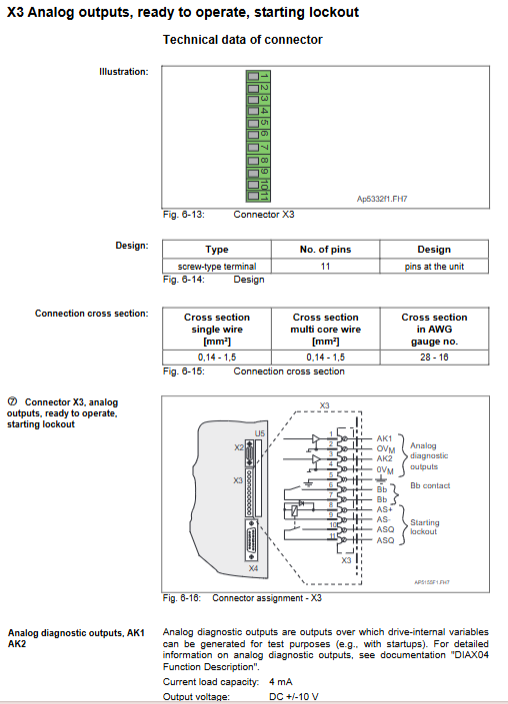

X5 interface (shared by both): DC bus, motor and power connection, EcoDrive 03 wiring cross-sectional area of up to 25mm ², tightening torque of 2.5-3.0Nm.

X6 interface (shared by both): motor temperature monitoring (TM+/-), brake control (BR+/-), wire diameter range 0.2-2.5mm ² (single core wire).

SERCOS interface (DIAX04 HDD): Connected via X10/X11 fiber optic cable, with a default data rate of 2Mbaud and switchable to 4Mbaud.

Wire diameter and cable length

The minimum wire diameter for the control voltage line (24V) is 1mm ², and the minimum wire diameter for loop transmission is 2.5mm ².

The maximum length of the motor cable is 75m (4kHz switching frequency), exceeding the required capacity reduction or length shortening (such as 25m for EcoDrive 03 8kHz).

(2) Installation requirements

Control cabinet and spacing

The minimum distance between the top of the equipment is 150mm, and the minimum distance between the bottom is 80mm (EcoDrive 03); The minimum spacing at the bottom of DIAX04 is 100mm.

The control cabinet shall be well sealed to avoid condensation, and the cooling unit shall avoid dripping or spray to electronic components.

Cooling requirements

If the ambient temperature exceeds 45 ℃, a cooling system must be configured, and the set temperature of the DIAX04 cooling system should not be lower than 40 ℃.

When multiple devices are installed side by side, an air guide device should be installed to avoid heat accumulation.

5、 Maintenance and Service

fault diagnosis

The device outputs error messages through status display and SERCOS interface, please refer to the corresponding troubleshooting guide.

DIAX04 provides a 24/7 service hotline, while EcoDrive 03 supports inquiries from global service outlets.

Repair and replacement

Repairs need to be carried out by original service personnel or trained personnel, and parameters need to be re debugged after replacing components.

The DIAX04 software module (HSM) can directly transfer parameters to replacement devices without the need for reprogramming.

Key points: EcoDrive 03 includes instructions for discharging DC bus capacitors, and the discharge resistance must meet the specification of 1000 Ω/1000W; DIAX04 includes transportation and storage requirements, with a temperature range of -30 ℃ to+85 ℃.

Leave a comment

Your email address will not be published. Required fields are marked *