How to properly install and maintain ABB’s REX 521 protective relay?

Installation points

Electrical installation specification: The electrical installation operation must be carried out by a professional qualified electrician, strictly following the national and local electrical safety regulations. For example, in the wiring process, make sure that the wiring is firmly connected and meets the electrical safety distance requirements to prevent short circuits, leakage and other safety hazards.

Grounding requirements: the frame of the protection relay needs to be carefully grounded, so as to ensure the safety of equipment operation and personnel safety, to avoid safety accidents caused by leakage.

Avoid electrostatic damage: Since the equipment contains components sensitive to electrostatic discharge, unnecessary touching of electronic components should be avoided to prevent electrostatic damage to them and affect the normal operation of the equipment.

Hardware Installation: Depending on the hardware version (Basic, Medium, High, and Sensor versions), connect the appropriate current and voltage transformers or sensors correctly. For example, when connecting current transformers, pay attention to their ratio and polarity to ensure the accuracy of the measurement and protection functions. At the same time, connect the digital inputs and outputs as well as the communication ports according to the terminal diagram to ensure correct connections.

Communication Setting: According to the actual use requirements, manually set the communication protocol (such as SPA, LON, IEC 60870 – 5 – 103, Modbus, DNP 3.0, etc.) and related parameters (such as baud rate, address, etc.) through HMI or Relay Setting Tool. For example, when using the Modbus protocol, parameters such as CRC Order, Modbus Mode, etc. should be set correctly to ensure stable and accurate communication.

Maintenance Points

Environmental inspection: If the environmental conditions (e.g. temperature, humidity) are not in accordance with the provisions of the technical data, or if there are chemically active gases or dust in the surrounding environment, it is necessary to carry out a visual inspection of the relay in conjunction with the secondary test, to see if there are any signs of mechanical damage or corrosion on the relay case and terminals.

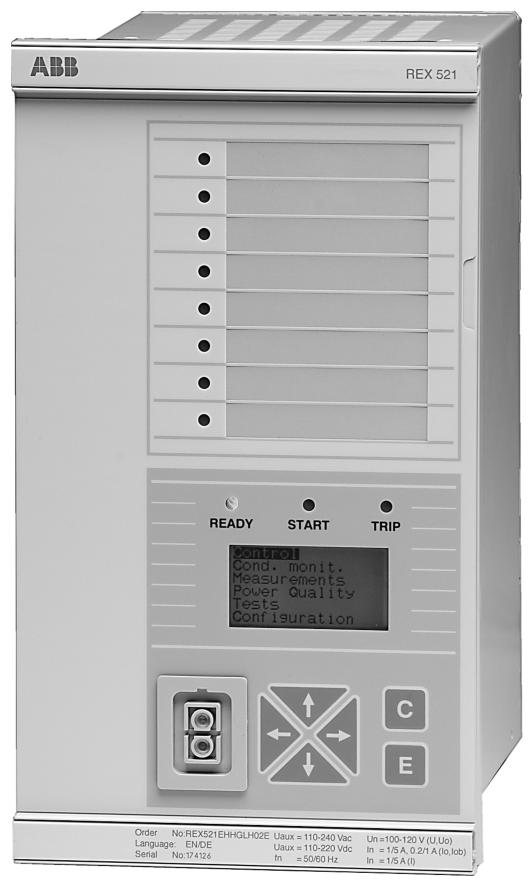

Daily inspection: During the operation of the equipment, it is necessary to check the operation status of the equipment regularly, to see whether the indicator lights are displayed normally, and to check whether the measurement data, event records, etc. are normal through the HMI or communication interface.

Troubleshooting: When the relay fails or the operating value differs greatly from the specification, it should be overhauled. Contact the manufacturer or its representative and follow professional instructions for inspection, overhaul and recalibration. For example, if an internal malfunction is detected, the cause of the malfunction needs to be accurately determined based on the malfunction codes and indication messages, and targeted repairs need to be performed.

Transportation protection: When transporting the protective relay, be careful and take measures against moisture and mechanical stress to prevent damage to the device. For example, use suitable packaging materials to ensure that the equipment is not affected by collision and moisture during transportation.

Leave a comment

Your email address will not be published. Required fields are marked *