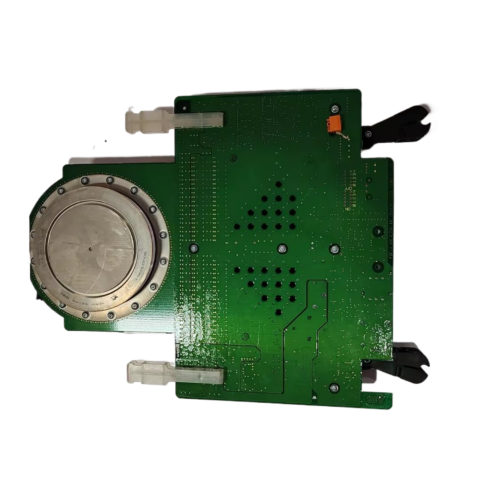

ABB IRB 2600-3HA/C039109-002 Gearbox

.png)

Product Parameters:

The ABB IRB 2600-3HA/C039109-002 is a versatile industrial robot designed for precision and efficiency. It features a payload capacity of up to 3 kg and a reach of 1,650 mm, making it ideal for a variety of applications. With a compact design and a lightweight structure, this model ensures easy integration into existing workflows. It operates with high speed and accuracy, thanks to its advanced motion control capabilities.

Usage Scenarios:

This robotic solution is well-suited for tasks such as assembly, material handling, and packaging in manufacturing environments. Its agility makes it a preferred choice for applications requiring quick cycle times and flexibility, including electronics production and automotive assembly lines.

Related Models:

For users considering alternatives, the ABB IRB 2600 is a similar model, offering robust performance in industrial automation. Other related models include ABB IRB 2400/1403/CR3, ABB 07DC91, ABB PM511V16 3BSE011181R1, ABB 3HAC16035-1, ABB 3HAC022436-001, ABB TB820-1 3BSE008556R1, ABB 3BHE012049R0101 UFD128A101, ABB 3HBE004573R0142 UFC760BE142, ABB GINT5611C, and ABB ACS880-01-246A-3 3ABD00035954-D.

Comparison with Other Models:

Compared to the ABB IRB 2400, the IRB 2600 offers a higher degree of flexibility and a more compact footprint, making it easier to deploy in tight spaces. In contrast to the ABB PM864AK01, the IRB 2600 prioritizes speed and precision, catering to fast-paced production lines. This model stands out for its adaptability, making it an excellent choice for modern manufacturing demands.

The above parameters are for reference only. Please contact our technical team for precise selection.

The ABB IRB 2600-3HA/C039109-002 is a versatile industrial robot designed for precision and efficiency. It features a payload capacity of up to 3 kg and a reach of 1,650 mm, making it ideal for a variety of applications. With a compact design and a lightweight structure, this model ensures easy integration into existing workflows. It operates with high speed and accuracy, thanks to its advanced motion control capabilities.

Usage Scenarios:

This robotic solution is well-suited for tasks such as assembly, material handling, and packaging in manufacturing environments. Its agility makes it a preferred choice for applications requiring quick cycle times and flexibility, including electronics production and automotive assembly lines.

Related Models:

For users considering alternatives, the ABB IRB 2600 is a similar model, offering robust performance in industrial automation. Other related models include ABB IRB 2400/1403/CR3, ABB 07DC91, ABB PM511V16 3BSE011181R1, ABB 3HAC16035-1, ABB 3HAC022436-001, ABB TB820-1 3BSE008556R1, ABB 3BHE012049R0101 UFD128A101, ABB 3HBE004573R0142 UFC760BE142, ABB GINT5611C, and ABB ACS880-01-246A-3 3ABD00035954-D.

Comparison with Other Models:

Compared to the ABB IRB 2400, the IRB 2600 offers a higher degree of flexibility and a more compact footprint, making it easier to deploy in tight spaces. In contrast to the ABB PM864AK01, the IRB 2600 prioritizes speed and precision, catering to fast-paced production lines. This model stands out for its adaptability, making it an excellent choice for modern manufacturing demands.

The above parameters are for reference only. Please contact our technical team for precise selection.

-480x480.png)

1-480x480.png)

-480x480.png)

-480x480.png)

-480x480.png)

There are no reviews yet.