1、 Cooperation foundation and positioning

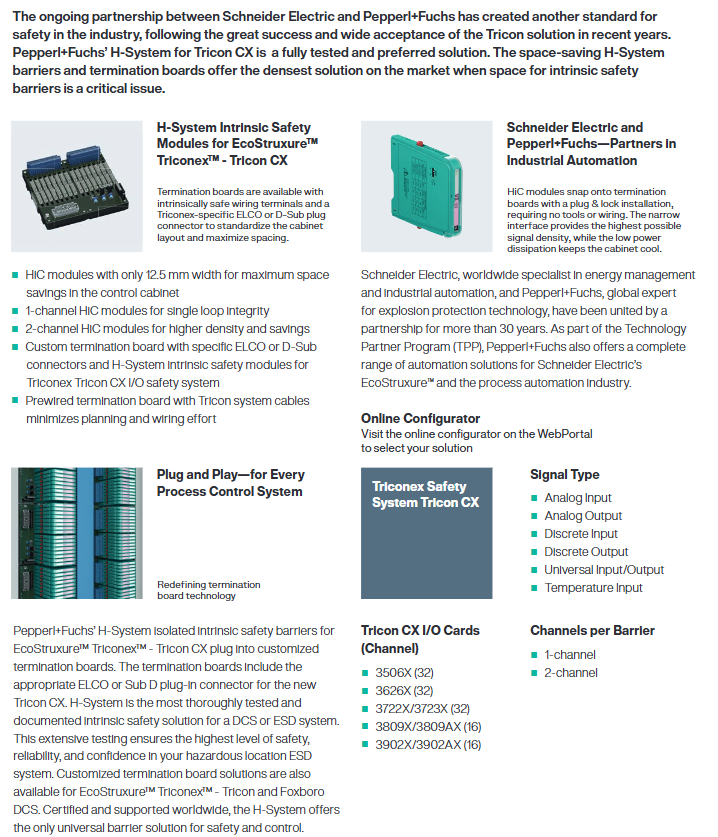

Collaboration partners: Pepperl+Fuchs (global expert in explosion-proof technology) and Schneider Electric (global specialist in energy management and industrial automation), with a cooperation period of over 30 years, are members of the Technology Partner Program (TPP).

Core objective: To contribute to Schneider Electric’s EcoStruxure ™ Triconex ™ Tricon CX security system (including ESD/DCS scenarios) provides customized and fully tested intrinsic safety terminal board solutions.

Applicable scenario: Hazardous location ESD system, which needs to meet explosion-proof and high safety level requirements in industrial scenarios.

2、 Core advantages of the product

Space saving: The HiC module has a width of only 12.5mm, making it the most signal dense intrinsic safety barrier solution on the market, suitable for scenarios where control cabinet space is tight.

Efficient installation: The HiC module adopts a “plug-in+locking” installation method, which does not require tools or additional wiring; Pre wired terminal boards paired with Tricon system cables significantly reduce planning and wiring workload.

Safe and reliable: The entire series of products have passed SIL 2/SIL 3 safety level certification and undergone extensive testing to ensure system safety and stability in hazardous environments.

Strong universality: supports multiple signal types such as digital, analog, temperature, and universal I/O, adapts to the full range of Tricon CX I/O cards, and provides customized Foxboro DCS solutions.

Low power design: The module has low power consumption and minimal heat dissipation, which helps maintain low-temperature operation inside the control cabinet and extends equipment lifespan.

3、 Product composition and key specifications

(1) Core module: HiC series

Channel configuration: 1 channel (single loop integrity), 2 channels (higher density and cost savings)

Size: 12.5mm wide, suitable for high-density installation requirements

Safety level: Supports SIL 2 and SIL 3 levels, covering different safety requirements scenarios

(2) Terminal board

Connector type: Tricon specific ELCO or D-Sub plug connector

Function: Standardize cabinet layout, maximize space utilization, pre wired design reduces installation complexity

(3) Tricon CX I/O Card Adaptation Details

Tricon CX I/O card model channel number adaptation HiC module model module function SIL level terminal board model terminal board channel number

3506X (digital input) 32 (16+16) HiC2821 relay output SIL 2 HICTB16-TRX-RAC-PL-DI16 16

HiC2841 transistor output SIL 2 16

HiC2822 relay output (2 channels) SIL 2 HICTB16-TRX-RAC-PL-DI32 32

HiC2842 transistor output (2-channel) SIL 2 32

3626X (digital output) 32 (16+16) HiC2871A 40mA @ 12VDC, resistant to test pulse SIL 3 HICTB16-TRX-RAC-PL-DO16 16

HiC2873 45mA @12VDC, Anti test pulse SIL 3 16

HiC2883 45mA @12VDC, Resistance to test pulses, LFT SIL 3 16

HIC5861 Safety Relay DTS (Non Intrinsic Safety) SIL 3 16

HIC5863 Safety Relay ETS (Non Intrinsic Safety) SIL 3 16

3722X/3723X (Analog Input) 32 (16+16) HiC2025 Universal Analog Input SIL 2 HICTB16-TRX-RAC-PL-AI16 16

HiC2025Y1 Analog Input SIL 2 16

HIC2025A Fire Detector Special (I ₀=93mA) SIL 2 16

HIC2025ES analog input SIL 3 16

3722X/3723X (temperature input) 32 (16+16) HiC2081 temperature input SIL 2 HICTB16-TRX-RAC-PL-AI16 16

3809X/3809AX (analog output) 16 HiC2031 analog output SIL 2 HICTB16-TRX-RAC-PL-IO16 16

HIC2031ES analog output SIL 3 16

3902X/3902AX (Universal I/O) 16 HiC2441 Universal (AI/AO/DI/DO) SIL 2 HICTB16-TRX-RAC-PL-IO16 16

(including the corresponding modules of AI/AO/TI/DI/DO mentioned above) -16

4、 Configuration and Additional Support

Online configuration tool: Through WebPortal online configurator, customized solutions can be selected based on signal type (analog/digital/temperature, etc.), Tricon CX I/O card model, and channel requirements.

Additional solutions: Pepperl+Fuchs also offers a full range of automation products including intrinsic safety galvanic isolators, signal conditioners, HART multiplexers, FOUNDATION Fieldbus/PROFIBUS solutions, blow and pressure systems, dedicated HMI solutions, and intrinsic safety mobile devices.

Global support: The product has obtained global certification and provides worldwide technical support and after-sales service.

Leave a comment

Your email address will not be published. Required fields are marked *