Honeywell Spyder® BACnet® Programmable Controllers

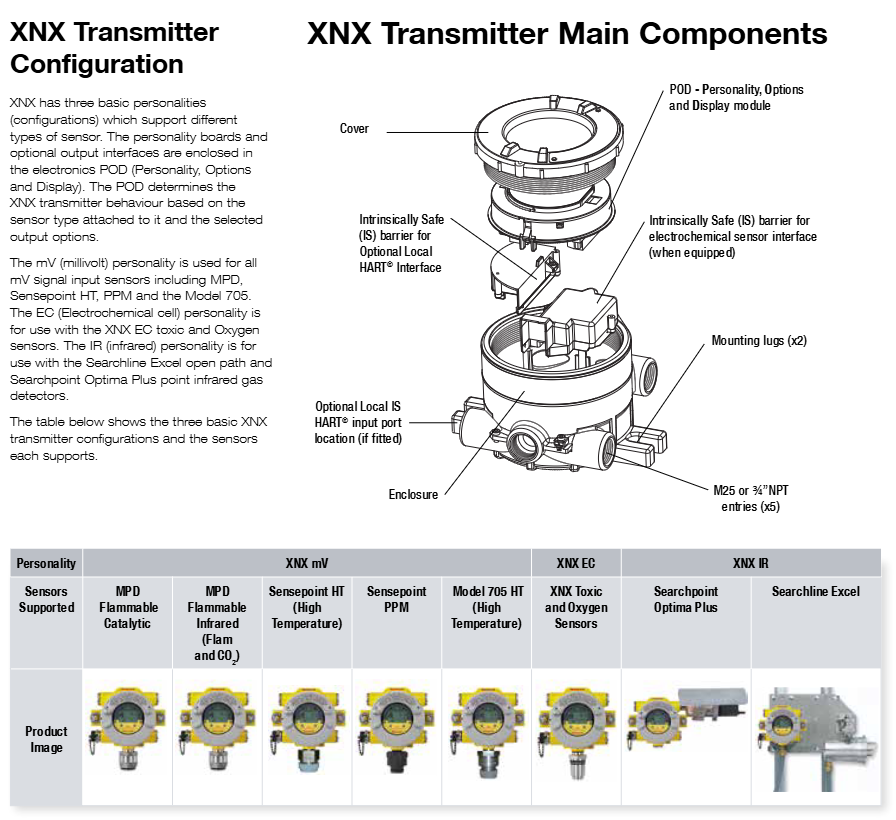

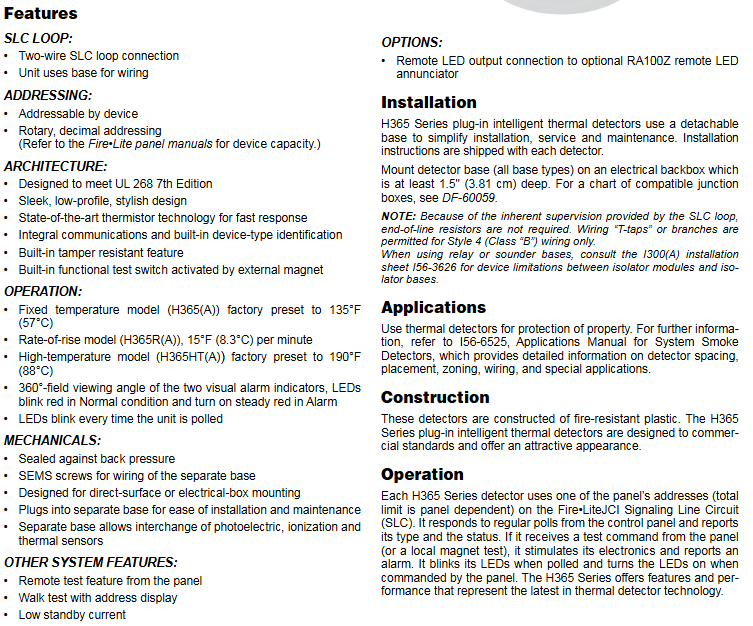

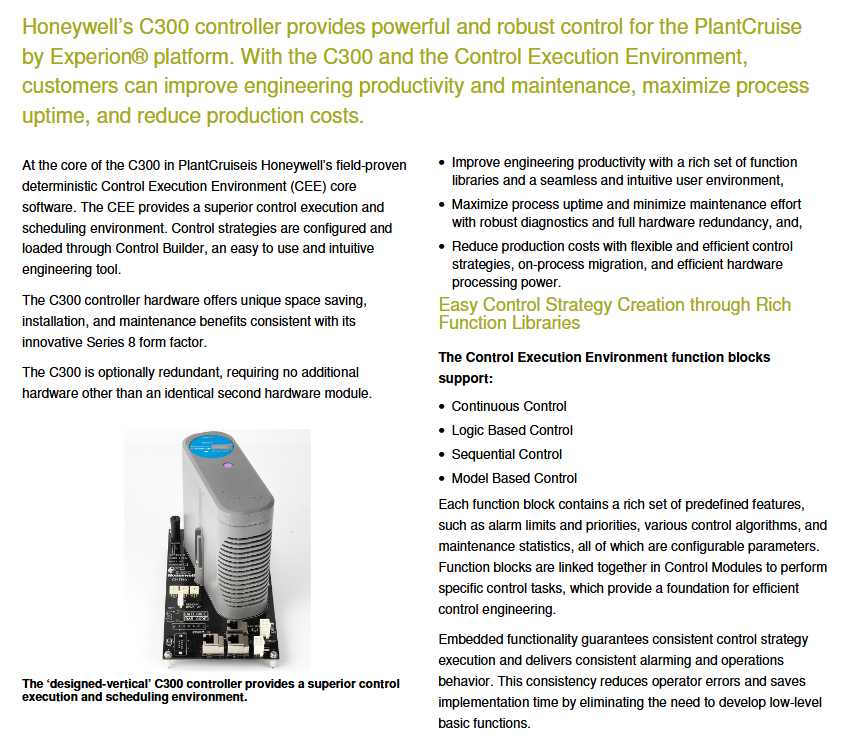

APPLICATION

The PUB and PVB controllers are part of the Spyder family. The nine controllers are BACnet MS/TP network devices designed to control HVAC equipment. These controllers provide many options and advanced system features that allow state-of-the-art commercial building control. Each controller is programmable and configurable using the NIAGARA FRAMEWORK® software.

The Spyder BACnet controllers require the Spyder BACnet Programmable Feature to be licensed in the WEBpro workbench tool and the WEBS AX JACE Controller for programming and downloading. The Spyder BACnet Models are also available as Individually Licensed Controllers (ILC). The ILC versions are identical in design and capability in every detail except for the licensing. The Individual Licensing of the Spyder ILCs (the License is built in) allows them to be programmed and downloaded with any brand of the Niagara Workbench or JACE controller. The Spyder ILCs are identified with a suffix on the Part Number of -ILC. Example: PUB6438S-ILC follows all the same Installation Instructions information as the PUB6438S.

The controllers are for use in VAV (Variable Air Volume), Unitary, and advanced HVAC control applications. Each controller contains a host microcontroller to run the main HVAC application and a second microcontroller for BACnet MS/TP network communications. Each controller provides flexible, universal inputs for external sensors, digital inputs, and a combination of analog outputs and digital outputs.

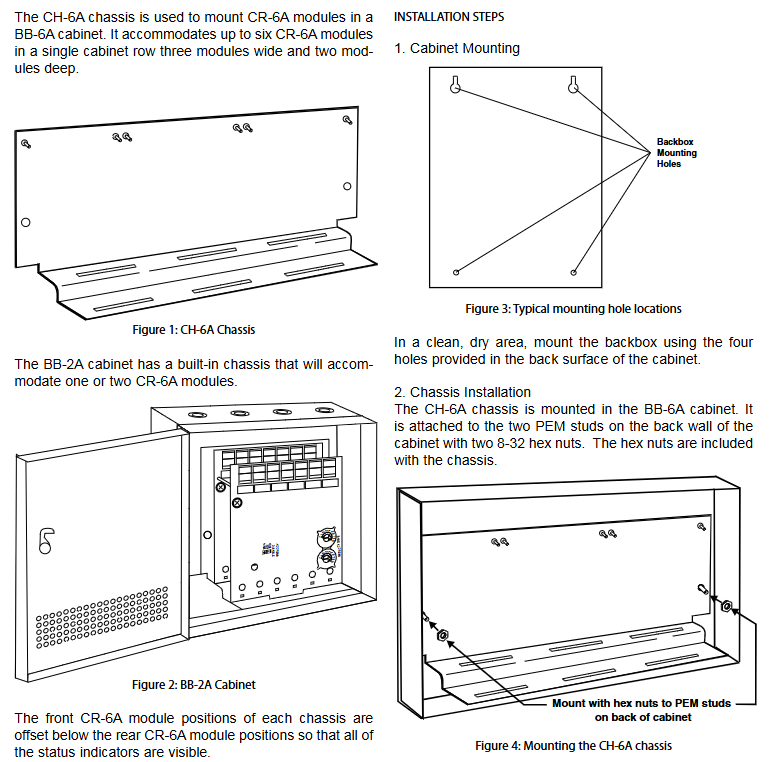

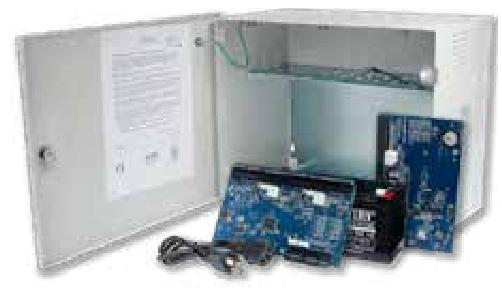

The photo shown is the PVB6436AS, which includes the Series 60 floating actuator.

FEATURES

• Uses BACnet MS/TP network communication.

• EIA-485 communications network. Capable of baud rates between 9.6 and 115.2 kbits/s.

• Capable of stand-alone operation, but can also use BACnet MS/TP network communications.

• Sylk™ bus for use with Sylk-enabled sensors.

• Support for up to 40 controllers per BACnet MS/TP segment (under 30 is recommended).

• Field configurable and programmable for control,input, and output functions using the NIAGARA FRAMEWORK ® software.

• Function Block engine, which allows the application designer to program the controller to perform a wide variety of HVAC applications.

• Built-in Zone Control functions include a remote wall module interface and a scheduler.

• Pressure-independent or pressure-dependent single or dual duct Variable Air Volume (VAV) control as well as Unitary equipment control.

• Microbridge air flow sensor with dual integral restrictor design (PVB0000AS, PVB4022AS, PVB4024NS, PVB6436AS, and PVB6438NS).

• Easy user access to air flow sensor inputs.

• Actuator (PVB0000AS, PVB4022AS, and PVB6436AS) mounts directly onto VAV box damper shaft and has up to 44 lb-in. (5 Nm) torque, 90 degree stroke, and 90 second timing at 60 Hz.

• All wiring connections are made to removable terminal blocks to simplify controller installation and replacement.

• Both controller housing and actuator are UL plenum rated.

AV Equipment Control

(PVB0000AS, PVB4022AS, PVB4024NS, PVB6436AS, and PVB6438NS)

The VAV controllers provide pressure-independent air flow control and pressure-dependent damper control. VAV systems generally provide cool air only to zones. However, each controller has additional programmable inputs and outputs that may be used to control devices, such as a fan or VAV box reheat coils. Heaters can be staged electric or modulating hot water. Supply and exhaust pressurization control are provided on a zone basis.

Unitary Equipment Control

(PUB1012S, PUB4024S, PUB6438S, and PUB6438SR)

Unitary equipment includes natural convection units, radiant panels, unit heaters, unit ventilators, fan coil units, and heat pumps. Unitary equipment does not require a central fan. Depending on design, unitary equipment may perform one or all of the functions of HVAC—ventilation, filtration, heating, cooling, humidification and distribution. Unitary equipment frequently requires a distribution system for steam or hot and or chilled water.

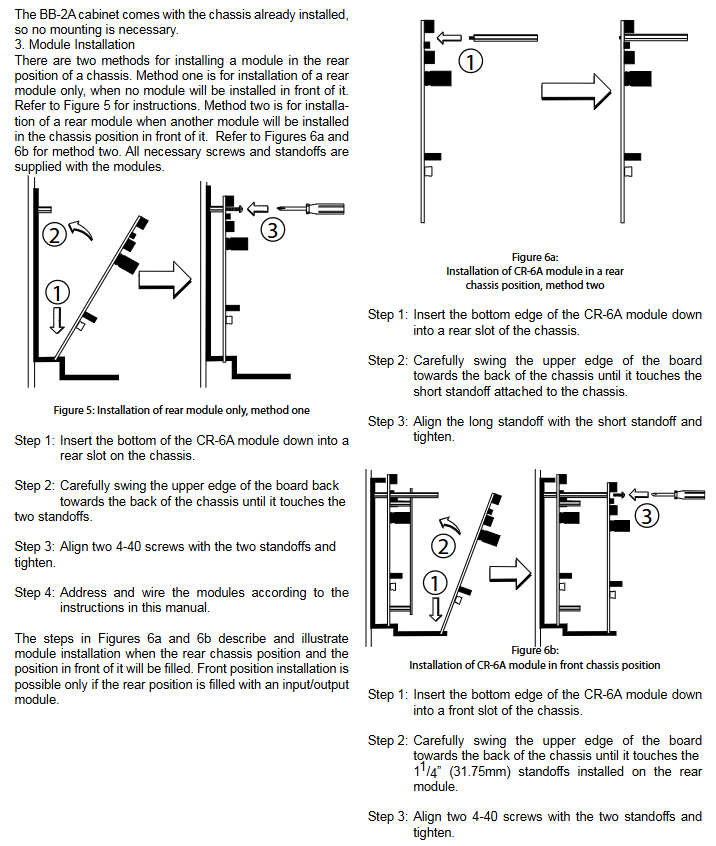

SPECIFICATIONS Electrical

Rated Voltage: 20-30 Vac; 50/60 Hz

Power Consumption:100 VA for controller and all connected loads (including

the actuator on model PVB6436AS)

Controller only Load: 5 VA maximum; models PVB6438NS,PUB6438S, and PUB6438SR

Controller and Actuator Load: 9 VA maximum; model PVB6436AS

External Sensors Power Output: 20 Vdc ±10% @ 75 mA maximum

Environmental VAV Operating & Storage Temperature Ambient Rating

(models PVB0000AS, PVB4022AS, PVB4024NS,PVB6436AS, and PVB6438NS):

Minimum 32° F (0° C); Maximum 122° F (50° C)Unitary Operating & Storage Temperature Ambient Rating

(models PUB1012S, PUB4024S, PUB6438S, and PUB6438SR):Minimum -40° F (-40° C); Maximum 150° F (65.5° C)

Relative Humidity: 5% to 95% non-condensing

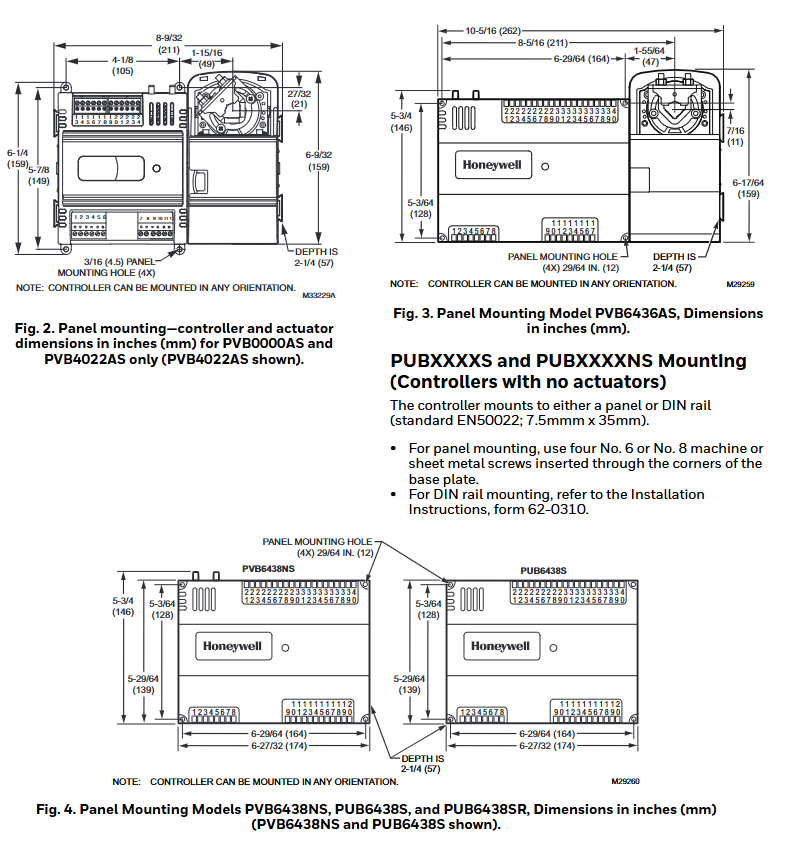

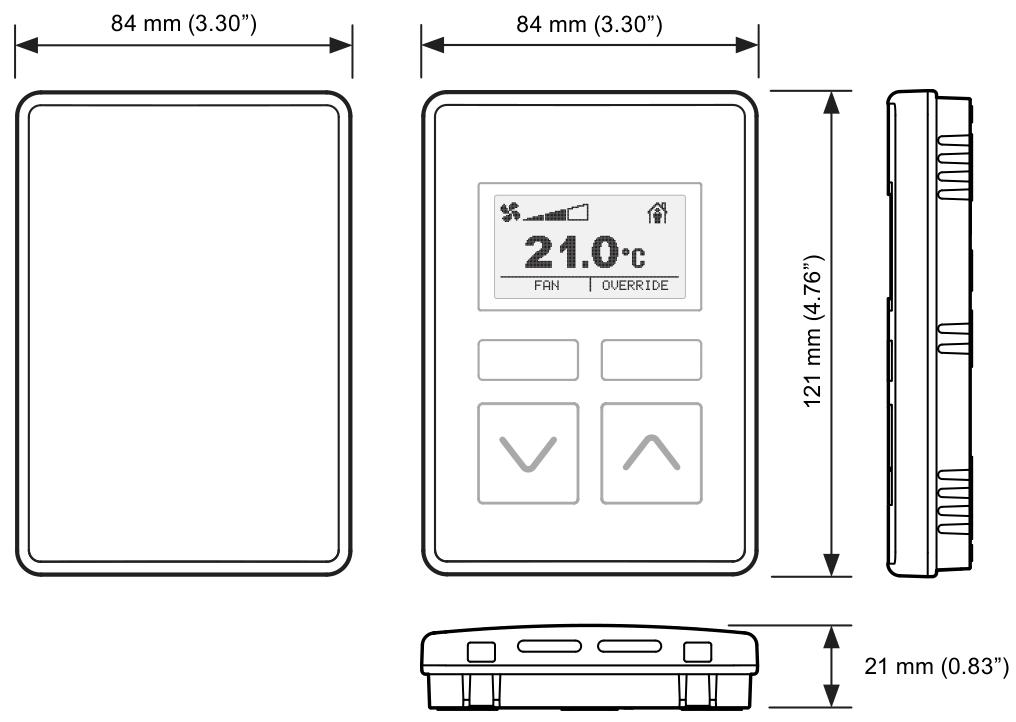

Dimensions (H/W/D)

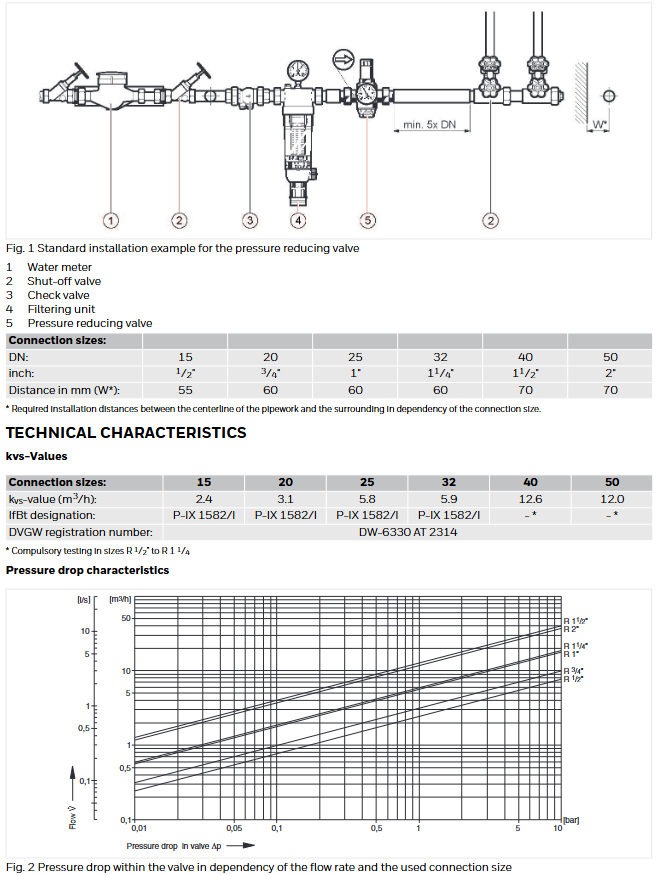

See Fig. 1 to Fig. 4 beginning on page 6 for dimensioned drawings.

PUB1012S, PUB4024S, and PVB4024NS:6.25 x 4.81 x 2.26 in. (15.92 x 12.20 x 5.74 cm)

PVB0000AS, PVB4022AS (including Actuator):6.60 x 8.28 x 2.26 in. (16.70 x 21.10 x 5.74 cm)

PVB6436AS (including Actuator): 6.27 x 10.316 x 2.26 in.(15.92 x 26.20 x 5.74 cm)

PVB6438NS: 5.76 x 6.85 x 2.26 in. (14.62 x 17.40 x 5.74 cm)

PUB6438S, PUB6438SR: 5.45 x 6.85 x 2.26 in. (13.84 x 17.40 x 5.74 cm)

Hardware (PVB0000AS, PUB1012S, PUB4024S, PVB4022AS, and PVB4024NS)

CPU

Each controller uses a 32 bit ATMEL ARM 7 microprocessor.

Memory Capacity

Flash Memory: 512 kilobytes. The controller is able to retain Flash memory settings for up to ten (10) years.

RAM: 128 kilobytes

Controller Status LED

The LED on the front of the controller provides a visual indication of the status of the device. When the controller receives power, the LED appears in one of the following allowable states, as described in Table 3.

Hardware (PUB6438S, PUB6438SR, PVB6436AS, and PVB6438NS)

CPU

Each controller uses a pair of microprocessors. The first is a 16-bit Texas Instruments MSP430 family microprocessor that is used to manage the Inputs, Outputs and Control. The second is a 32-bit ATMEL ARM 7 microprocessor that manages communication for the Spyder BACnet.

Memory Capacity

Flash Memory: 372 kilobytes. The controller is able to retain Flash memory settings for up to ten (10) years.

RAM: 72 kilobytes

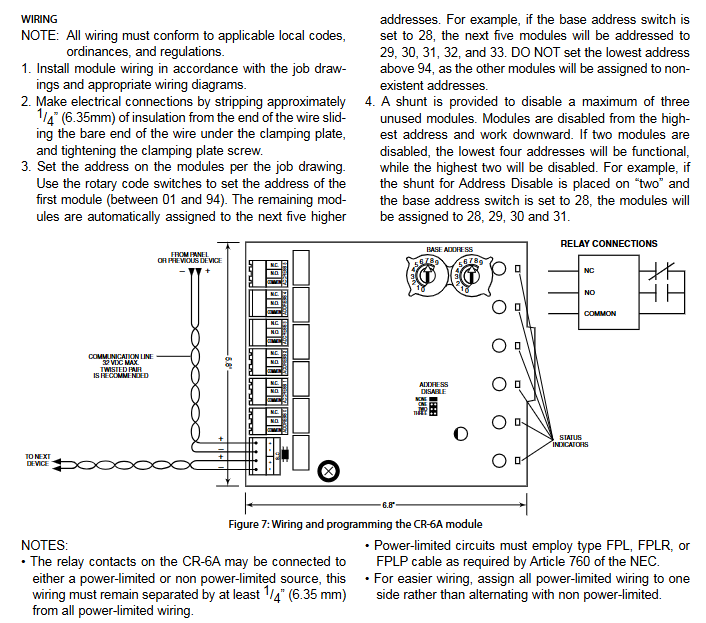

MS/TP MAC Address

The MS/TP MAC address for each device must be set to a unique value in the range of 0-127 on an MS/TP network segment. DIP switches on the Spyder BACnet controller are used to set the controller’s MAC address.

Device Instance Number

The Device Instance Number must be unique across the entire BACnet system network because it is used to uniquely identify the BACnet devices. It may be used to conveniently identify the BACnet device from other devices during installation. The Spyder BACnet Controllers Device Instance Number is automatically set when it is added to a WEBStation-AX project. The Device Instance Number can be changed by the user, which may be necessary when integrating with a third party or when attempting to replace an existing controller and it is desired to maintain the existing Device Instance Number.

Termination Resistors

Matched terminating resistors are required at each end of a segment bus wired across (+) and (-). Use matched precision resistors rated 1/4W ±1% / 80 – 130 Ohms. Ideally, the value of the terminating resistors should match the rated characteristic impedance of the installed cable. For example, if the installed MS/TP cable has a a listed characteristic impedance of 120 Ohm, install 120 Ohm matched precision resistors.

Shield Terminating

Following proper MS/TP cabling shield grounding procedures is important to minimize the risk of communication problems and equipment damage caused by capacitive coupling. Capacitive coupling is caused by placing MS/TP cabling close to lines carrying higher voltage. The shield should be grounded on only one end of the MS/TP segment (typically the router end). Tie the shield through using the SHLD (terminal 4) on the Spyder BACnet Controller.

Sylk™ Bus

Sylk is a two wire, polarity insensitive bus that provides both 18 VDC power and communications between a Sylkenabled sensor and a Sylk-enabled controller. Using Sylkenabled sensors saves I/O on the controller and is faster and cheaper to install since only two wires are needed and the bus is polarity insensitive. Sylk sensors are configured using the latest release of the Spyder Tool for WEBPro and WEBStation.