Honeywell HA-20, HA-40, and HA-71 gas detection controllers

Product Family Overview

The HA-20, HA-40, and HA-71 series gas detection controllers launched by Honeywell are designed specifically for monitoring gas detection points from 1 to 16 channels, balancing high safety and cost-effectiveness. These controllers are suitable for harsh industrial or commercial environments, with NEMA 4X and explosion-proof enclosure options, and can be deployed in hazardous areas for monitoring toxic gases, flammable gases, and oxygen content. The core advantages are multi-channel monitoring, flexible expansion, and high environmental adaptability.

Core functions and features of each model

HA-20 and HA-40 controllers

Channels and inputs:

HA-20 supports 2 4-20mA sensor inputs, HA-40 supports 4, both of which are suitable for long-distance sensor signal transmission.

Built in 24VDC power supply, with a total power of 15W (optional 50W power supply to expand wiring space).

Alarm and Control:

Each channel contains 3 independent alarm levels and supports relay confirmation function (can mute external sound devices when an alarm is triggered).

Standard configuration includes 2 SPDT common alarm relays (for HORN, HIGH, Warning, or FAULT states), and optional independent channel alarm relays.

Display and operation:

Graphic LCD display screen, displaying data in bar charts, trend charts, and engineering units; The alarm LED flashes when a new alarm is triggered and remains on after confirmation.

Adopting touch and magnetic keyboards, supporting non-invasive operations in hazardous areas; Equipped with calibration mode (zero/range calibration) and authorization mode (locking key configuration parameters).

Certification and compatibility:

Obtained CSA certification (C22.2 NO.152), suitable for combustible gas detection, compliant with Class I, Div. 2, Groups A, B, C, D, and CE markings.

Optional RS-485 Modbus slave port (supporting 128 HA-40 multi machine networking) or 10 BaseT Ethernet (Modbus TCP/IP protocol).

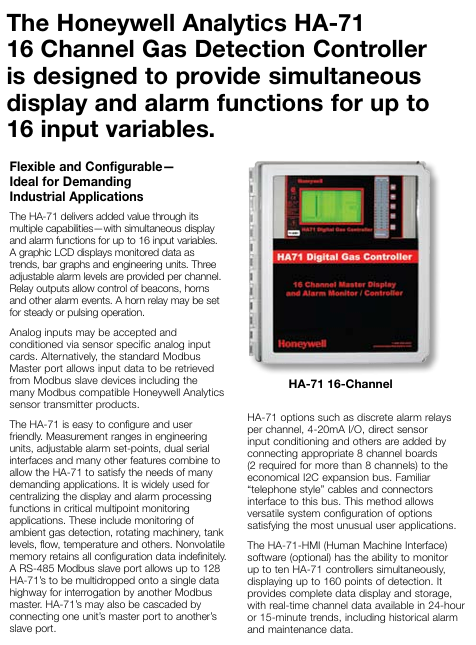

HA-71 controller

Channels and inputs:

Supports up to 16 inputs, compatible with analog signals or Modbus protocol, and can obtain data through RS-485 to reduce wiring costs.

Provide 8-channel display mode, with optional expansion board to meet economical configurations below 8 channels.

Functions and extensions:

Each channel has 3 adjustable alarm levels and is equipped with SPDT common alarm relays (HORN, HIGH, Warning, FAULT) as standard.

Supports dual Modbus RS-485 serial ports and optional telephone modems, and adds discrete alarm relays, 4-20mA I/O, and other functions through the I ² C expansion bus (2 expansion boards are required for channels exceeding 8).

Software and Monitoring:

HA-71-HMI software is optional, which can simultaneously monitor 10 HA-71 controllers (up to 160 detection points), support real-time data display, 24-hour/15 minute trend analysis, and historical alarm recording.

Common advantages and applicable scenarios

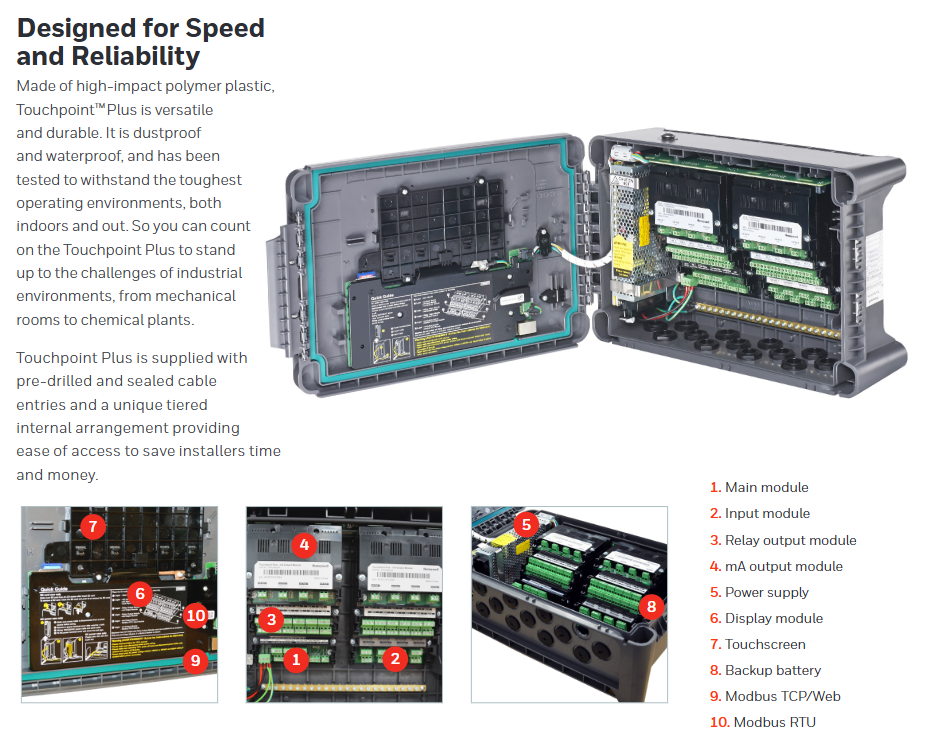

Environmental adaptability: Both provide NEMA 4X (Div. 2 certification) and explosion-proof wall mounted enclosure options, suitable for deployment in hazardous areas.

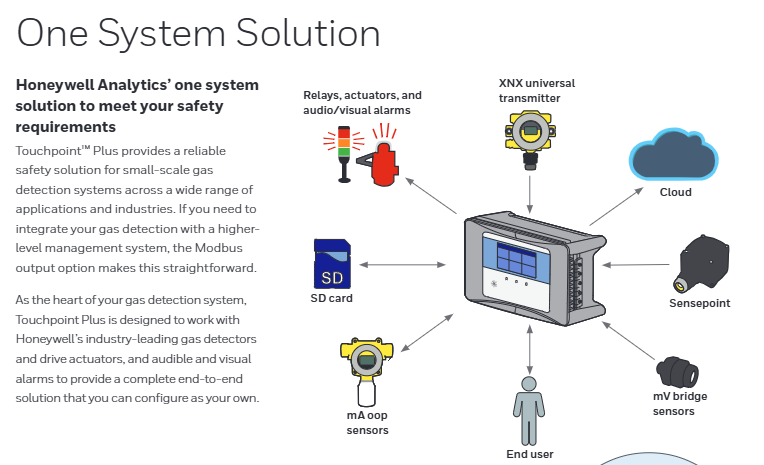

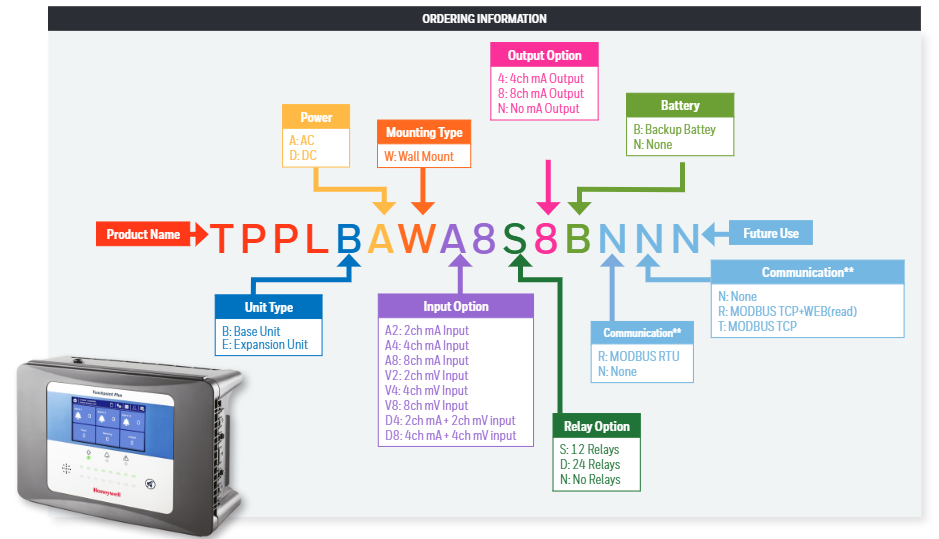

Flexibility: Supports optional functions such as Modbus protocol (RS-485 or TCP/IP), data recording, 4-20mA output, etc., to meet different integration requirements.

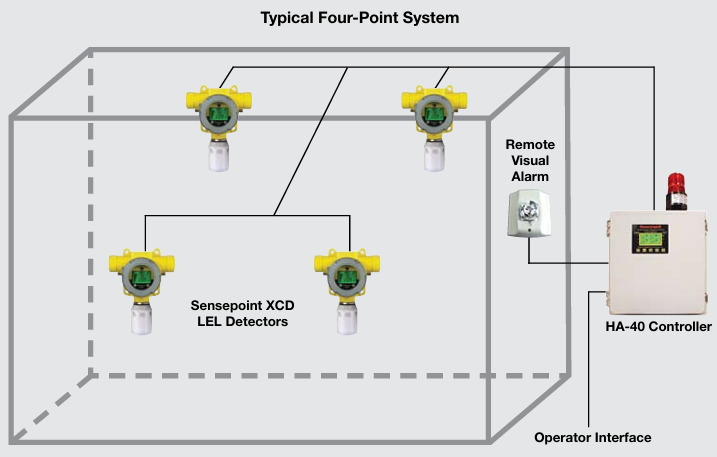

Typical application: Suitable for multi-point gas monitoring scenarios, such as factory workshops, chemical facilities, etc., it can be linked with Sensepoint XCD and other detectors to form a complete system (such as a typical four point system including HA-40 controller, remote visual alarm, and operator interface)