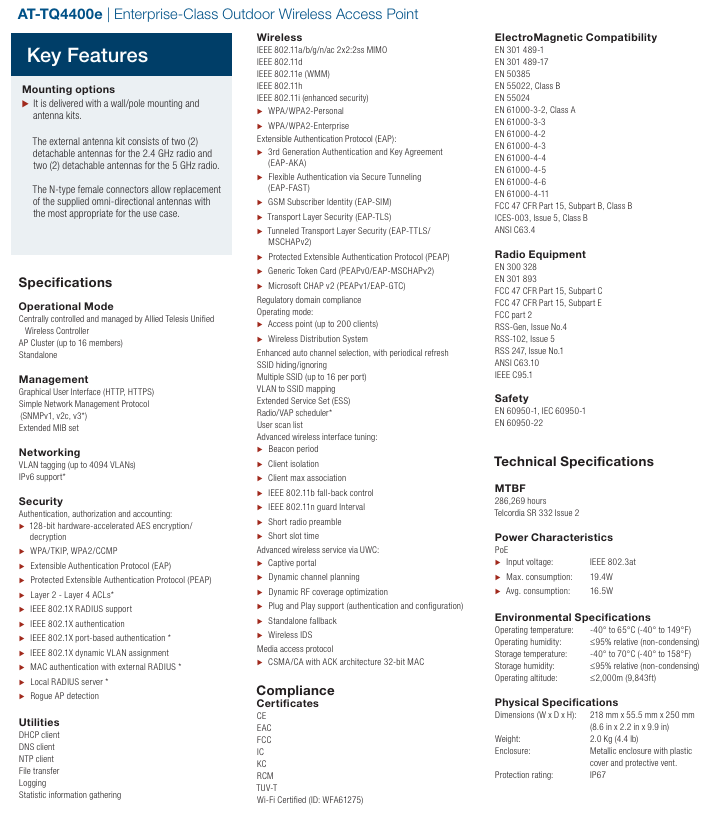

Allied Telesis AT-TQ4400e Enterprise Outdoor

Core positioning and key characteristics

AT-TQ4400e is an enterprise level outdoor wireless access point launched by Allied Telesis, which focuses on stable wireless coverage and enterprise level functional support in outdoor scenarios. Its core features focus on flexible installation and antenna configuration:

Installation and antenna: standard wall/pole installation kit and antenna kit; The antenna includes 2 detachable 2.4GHz antennas and 2 detachable 5GHz antennas, and supports the replacement and adaptation of omnidirectional antennas for different scenarios through N-type female connectors, meeting diverse outdoor deployment needs.

Core functional specifications

1. Operation mode and management

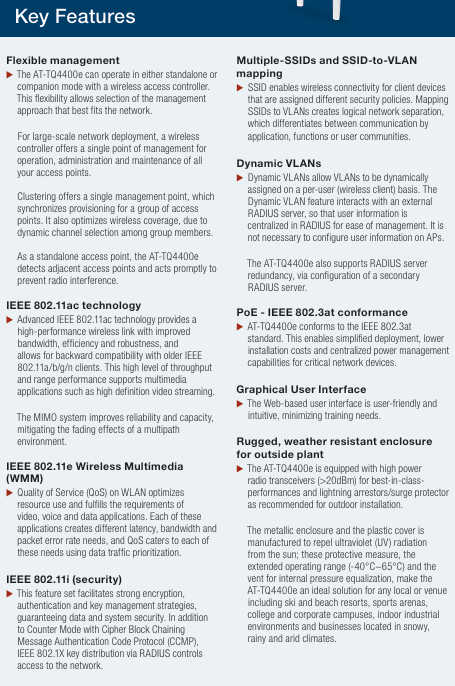

Operation mode: Supports three core modes to meet different networking needs – centralized control by Allied Telesis Unified Wireless Controller (UWC), AP cluster (up to 16 members), and standalone operation.

Management method: Provide graphical user interface (HTTP/HTTPS), simple network management protocol (SNMP v1/v2 c/v3 *), and extended MIB set, balancing visual operations and standardized network management.

Note: The “” function requires software version v3.2.1 or above support, the same applies below.

2. Network and Security

Network capability: Supports VLAN tagging (up to 4094 VLANs) and IPv6 *, enabling fine-grained network partitioning and adaptation to next-generation network protocols.

Security protection:

Encryption and Authentication: 128 bit hardware accelerated AES encryption and decryption, supporting WPA/TKIP, WPA2/CCMP, as well as various authentication protocols such as EAP and PEAP; Compatible with IEEE 802.1X (including port based authentication *, dynamic VLAN allocation), MAC authentication (requiring external RADIOUS *), and built-in local Radius server *.

Risk prevention and control: equipped with Rogue AP detection (rogue AP refers to unauthorized access points that can prevent illegal devices from accessing the network), 2-4 layers of ACL * (access control list, restricting illegal traffic), to ensure network security boundaries.

3. Wireless function

Protocol and Performance: Compatible with IEEE 802.11a/b/g/n/ac, using 2×2:2ss MIMO technology; A single AP can support up to 200 client accesses, with 802.11ac speeds reaching 6.5-867Mbps (MCS 0-9, NSS 1-2) and 802.11n speeds ranging from 6.5-300Mbps, meeting high concurrency and high bandwidth requirements.

Wireless optimization: supports enhanced automatic channel selection (periodic refresh), SSID hiding/ignoring (up to 16 SSIDs per port), VLAN and SSID mapping, client isolation, maximum association limit, etc; It is also possible to implement captive portal, dynamic channel planning, dynamic RF coverage optimization, plug and play (authentication and configuration), and wireless IDS (intrusion detection system) through UWC.

Authentication Extension: The EAP protocol family covers all aspects, including EAP-AKA, EAP-FAST, EAP-SIM, EAP-TLS, EAP-TTLS/MSCHAPv2, PEAP (including PEAPv0/EAP-MSCHAPv2, PEAPv1/EAP-GTC), and is compatible with different enterprise authentication systems.

4. Practical tools

Built in DHCP client, DNS client, NTP client (time synchronization), supporting file transfer, logging, and statistical information collection, facilitating network deployment, maintenance, and problem troubleshooting.

Hardware and environmental specifications

1. Technical and physical parameters

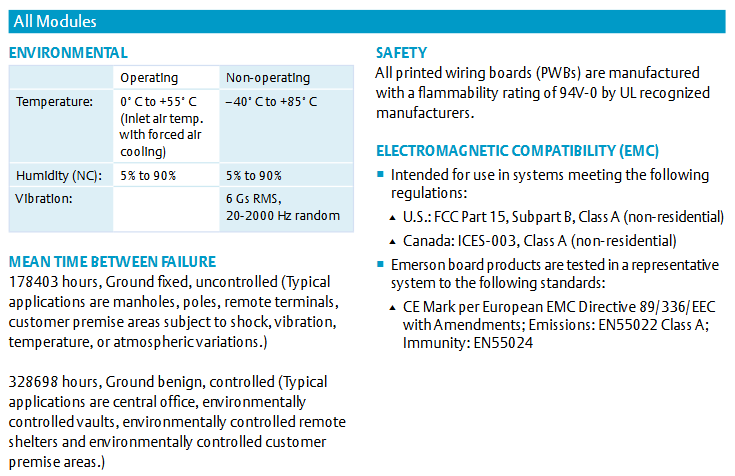

MTBF (Mean Time Between Failures): 286269 hours (based on Telcordia SR 332 Issue 2 standard), excellent stability.

Power supply: Supports IEEE 802.3at PoE standard, with power consumption of 19.4W and 16.5W respectively.

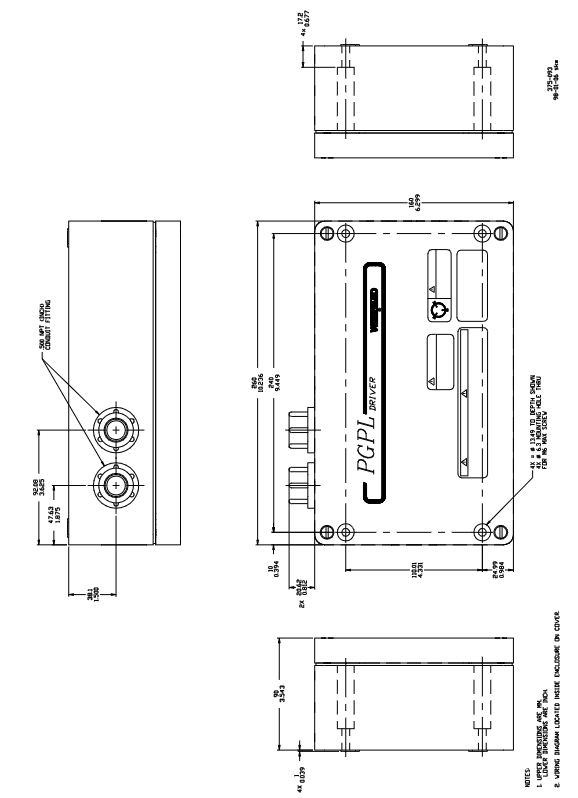

Physical dimensions and weight: 218mm x 55.5mm x 250mm (8.6in x 2.2in x 9.9in), weight 2.0Kg (4.4lb), suitable for outdoor installation.

Protection level: IP67 (dustproof, short-term immersion), with a metal shell, plastic cover, and protective ventilation opening, suitable for harsh outdoor environments.

2. Environmental adaptability

Temperature: Operating temperature -40 ° C to 65 ° C (-40 ° F to 149 ° F), storage temperature -40 ° C to 70 ° C (-40 ° F to 158 ° F), strong resistance to high and low temperatures.

Humidity: Both working and storage humidity are ≤ 95% relative humidity (without condensation), suitable for humid environments.

Altitude: Working altitude ≤ 2000m (9843ft), covering most outdoor deployment scenarios.

Compliance and Certification

1. Product certification

Certified by CE, EAC, FCC, IC, KC, RCM, TUV-T, and Wi Fi Certified (ID: WFA61275), it meets the market access standards and wireless compatibility requirements of major global regions.

2. Electromagnetic compatibility (EMC) and wireless device compliance

EMC: Complies with EN 301 489-1/-17, EN 50385, EN 55022 (Class B), EN 55024, EN 61000 series standards, as well as FCC 47 CFR Part 15 Subpart B (Class B), ICES-003 Issue 5 (Class B), etc., to reduce electromagnetic interference to peripheral devices.

Wireless devices: comply with EN 300 328, EN 301 893, FCC 47 CFR Part 15 Subpart C/E/Part 2, RSS series standards, etc., to ensure compliant transmission of wireless signals.

3. Safety standards

Complies with EN 60950-1, IEC 60950-1, and EN 60950-22 safety standards to ensure electrical safety during equipment use.

Frequency and Modulation

1. Support frequency (subject to regulatory restrictions in various countries)

2.4GHz ISM band: 2.400~2.4835GHz

5GHz U-NII frequency band: 5.150~5.250 GHz(U-NII-1)、5.250~5.350GHz(U-NII-2A)、5.470~5.725GHz(U-NII-2C)、5.725~5.850GHz(U-NII-3)

2. Modulation technology

802.11a/g/n/ac: using OFDM modulation

802.11b: Uses DSSS, CCK, DQPSK, DBPSK modulation

802.11ac additionally supports BPSK, QPSK, 16QAM, 64QAM, 256QAM, and 802.11a/g/n supports BPSK, QPSK, 16QAM, and 64QAM to ensure signal quality at different rates.

3. Transmission power

The maximum transmission power exceeds 20dBm, and the signal strength will be automatically limited according to the selected regulatory domain and installed antenna, in compliance with local regulatory requirements.

Ordering and associated products

1. Ordering Information

The product model is AT-TQ4400e-xx, where “xx” represents the regulatory domain:

No suffix: globally applicable (except for the United States and Canada)

01: Exclusive for the United States and Canada (reserved)

2. Related products

AT-UWC-60-APL: Enterprise grade wireless LAN controller (hardware device) used for centralized control of APs

AT-UWC BaseST: Enterprise grade wireless LAN controller (software installation package, including 10 AP management licenses)

AT-TQ4600: Enterprise grade wireless access point (including IEEE 802.11ac dual band radio and built-in antenna), which can be used as a supplement for indoor or different scenarios.