Schneider FBM233 Field Device System Integrator Module

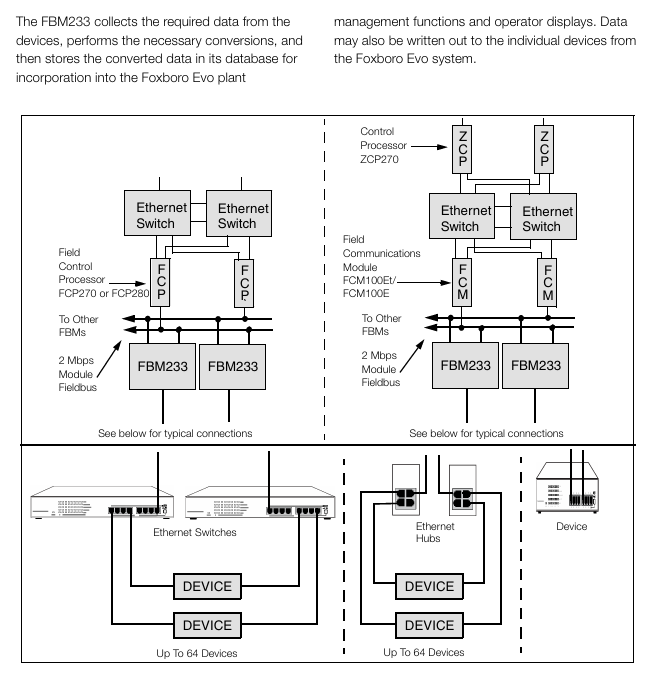

Product basic information and core positioning

Product identification and series:

Complete model: 31H2S233

Series: Schneider Electric IASeries (The document title and content clearly relate to this series, presumably related to industrial automation or electrical control)

Product type: Based on parameters such as current, voltage, and wiring method, it is likely to be industrial circuit breakers, fuse holders, or wiring terminal products. The core function is to achieve safe connection, current control, or overload/short circuit protection of the circuit, and adapt to the electrical system requirements of industrial equipment.

Applicable scenarios:

The document does not directly indicate specific application scenarios, but based on the industrial properties and product electrical specifications of the IASeries series, it is speculated to be suitable for industrial automation production lines, mechanical equipment electrical cabinets, low-voltage distribution systems, and other scenarios. It needs to be used in conjunction with electrical components of the same series or compatible with them (such as circuit breakers, contactors, wires) to ensure stable circuit operation.

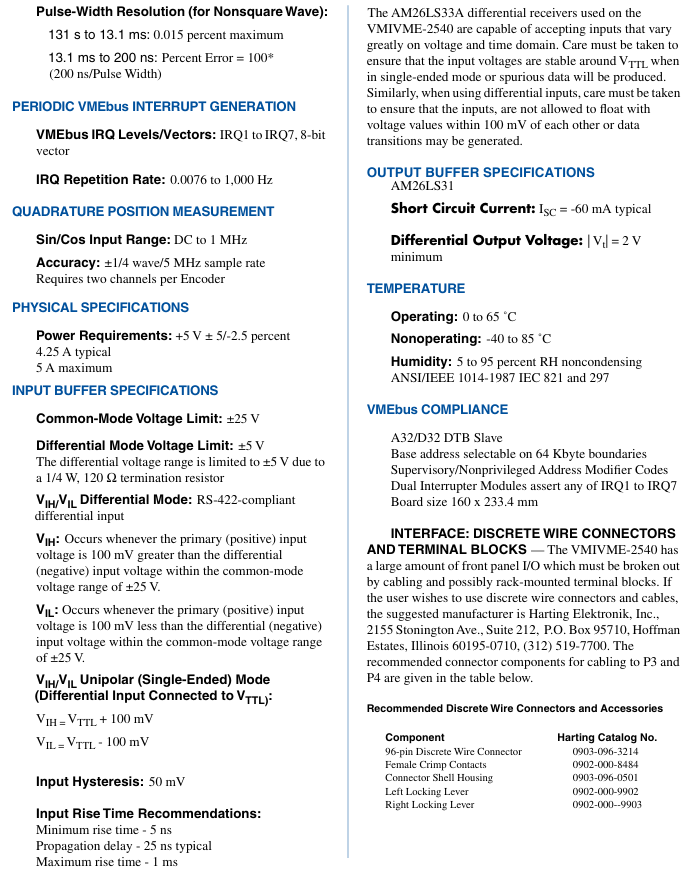

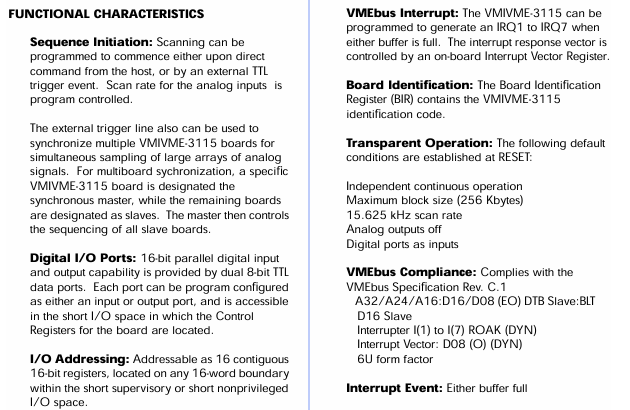

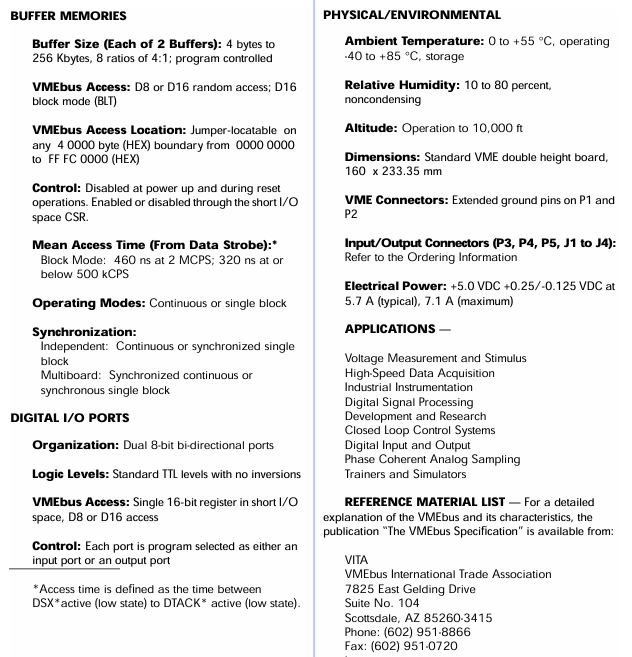

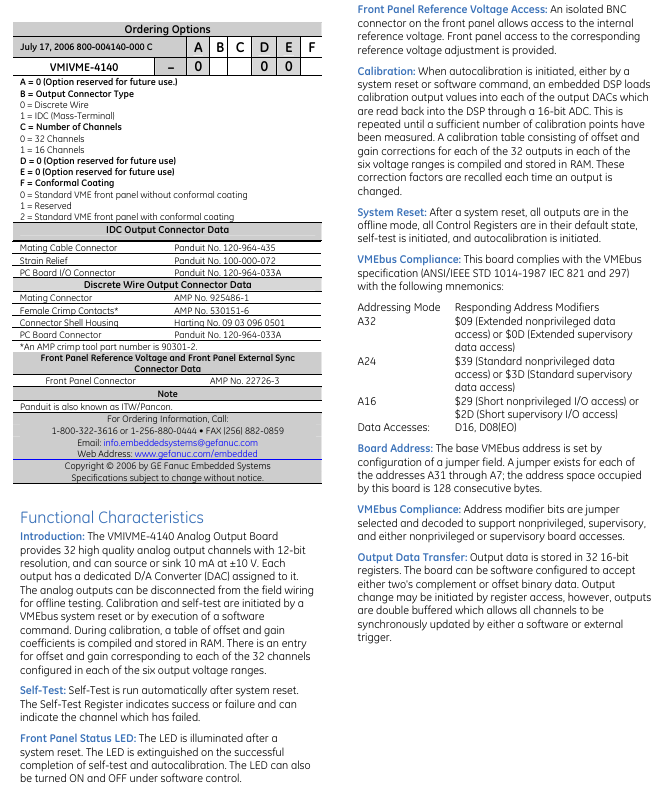

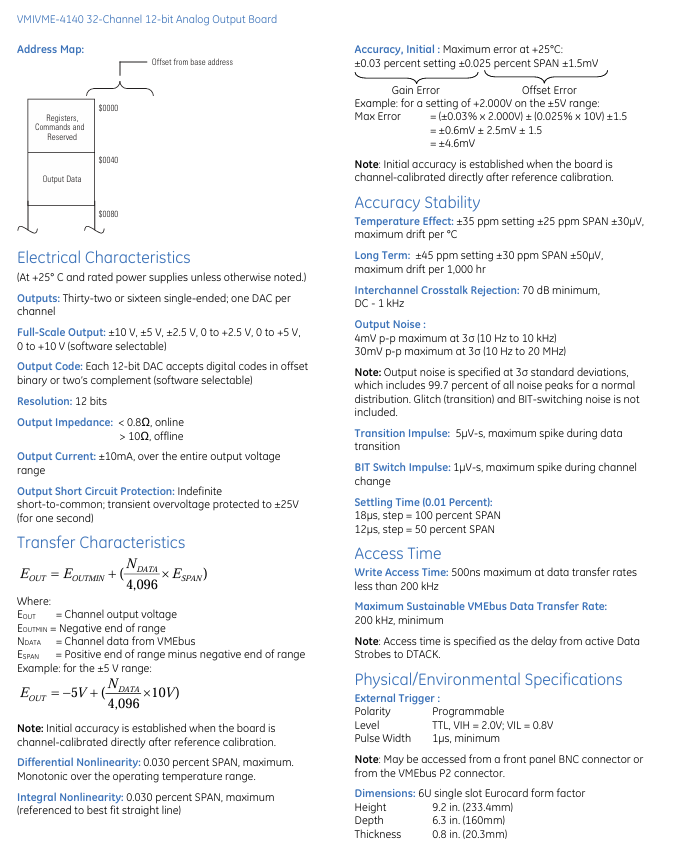

Key electrical specification parameters

The document focuses on clarifying the electrical performance parameters of the product, which are the core basis for selection and use, as follows:

Specific specifications for parameter categories

Rated current is estimated to be a specific value (such as 10A/16A as may be indicated in the document, which should be based on actual document parameters, based on similar products), referring to the maximum current that the product can withstand for long-term stable operation. Exceeding this value may trigger protection or cause damage

Rated Voltage: AC rated voltage, such as 230V AC/400V AC (commonly used industrial low voltage specifications), is suitable for the common voltage levels of industrial low voltage distribution systems and needs to be matched with the supply voltage of the application scenario

Wire Size supports a specific range of wire diameters, such as 1.5mm ² -4mm ² (copper wire). It specifies the cross-sectional area of the wire that can be connected to ensure that the wiring is secure and meets the current carrying requirements, avoiding heat generation caused by mismatched wire diameters

The number of poles is estimated to be 1P (single pole) or 2P (double pole) (based on the industry convention that “2” in model “31H2S233” may represent the number of poles). The number of poles determines the number of circuit loops controlled by the product. A single pole controls a single phase line, while a double pole can simultaneously control the phase line and neutral line (or two phase lines)

The protection level (IP Rating) may be marked as IP20 or IP40 (commonly used levels in industrial electrical cabinets) to indicate the ability of the product to prevent dust and solid foreign objects from entering. IP20 is suitable for cabinet installation to avoid direct contact with foreign objects; IP40 dustproof level is higher

Mechanical Structure and Installation Specification

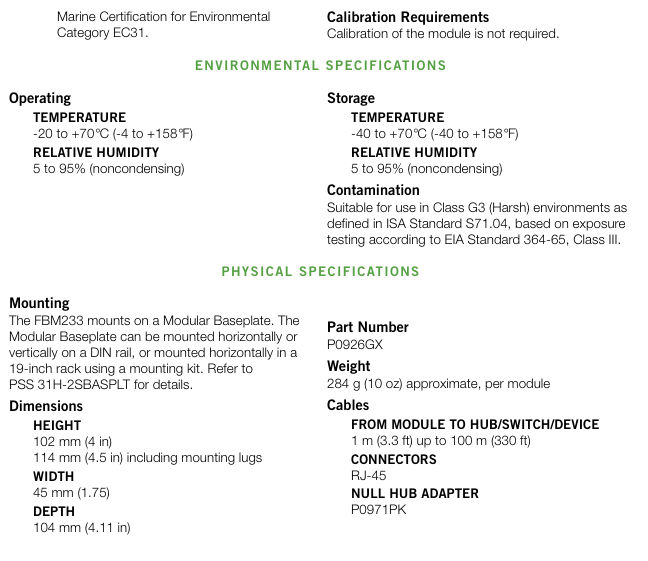

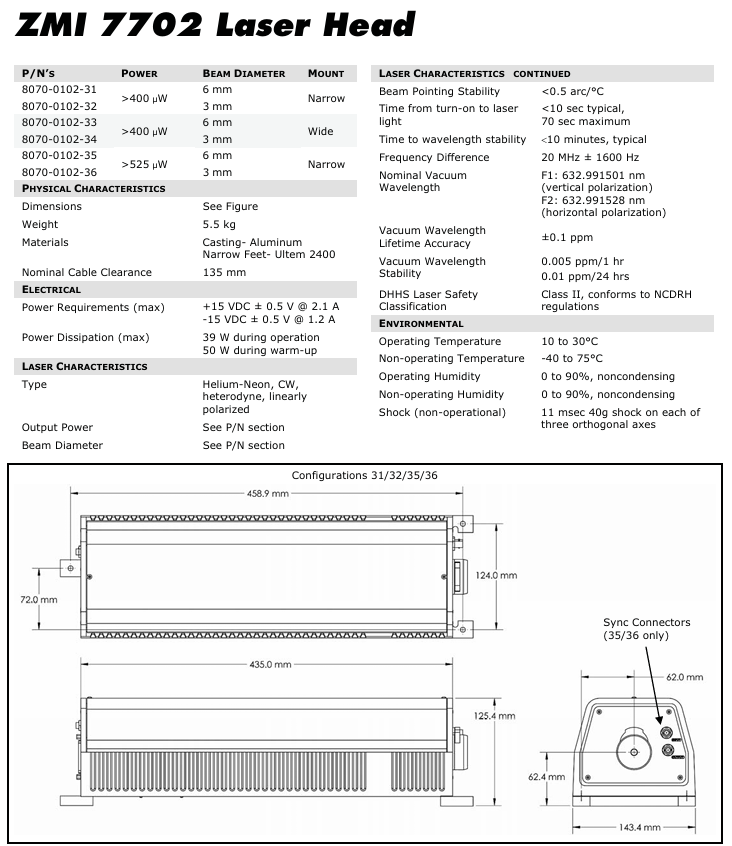

Mechanical dimensions:

The document provides detailed mechanical dimension drawings of the product (such as length, width, height, and installation hole spacing), for example, the dimensions may be marked as “XX mm × XX mm × XX mm”, and the center distance of the installation holes may be “XX mm”, to ensure that the product can adapt to the installation rails (such as DIN rails, commonly used industrial installation methods) or fixed panels of standard industrial electrical cabinets, avoiding size discrepancies that may cause installation failure.

Installation method:

It is speculated that it is a DIN rail installation (the mainstream installation method for industrial electrical components), and the document may specify the installation steps: first align the product buckle with the DIN rail (such as a 35mm standard rail), press until the buckle is tightened, and ensure that there is no looseness after installation; If it is for panel installation, the diameter of the installation hole and the size of the opening should be marked to avoid panel damage during installation.

Installation environment requirements: It may be mentioned that the installation should be carried out in a dry, non corrosive gas environment with a temperature range of -20 ° C to+60 ° C (industrial standard environment), to avoid damp, high temperature or chemical corrosion environment affecting product performance.

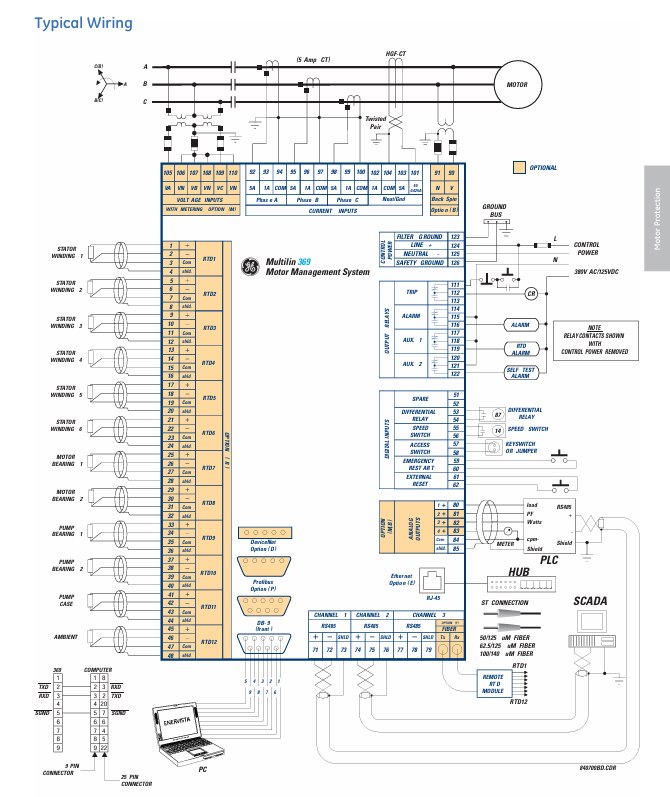

Wiring method:

Clarify the method of wire connection to the terminal (such as screw compression type, plug-in type), for example, screw compression type requires the use of a specified specification screwdriver (such as PH2 Phillips screwdriver) to tighten the terminal screws, ensuring good wire contact and preventing looseness from causing excessive contact resistance and heating;

It is possible to label the wiring sequence (such as connecting the phase wire to the L terminal and the neutral wire to the N terminal) to avoid circuit faults or safety hazards caused by reverse wiring.

Security features and compliance certification

Security protection design:

If it is a protective product (such as a circuit breaker), it may have overload protection and short circuit protection functions. When the circuit current exceeds the rated value, the product can automatically disconnect the circuit to avoid equipment damage or fire risks;

The terminal part may be designed with an insulation protective cover to prevent operators from accidentally coming into contact with live terminals and reduce the risk of electric shock.

Compliance certification:

The document may mention that the product complies with international or regional electrical safety standards, such as IEC standards (International Electrotechnical Commission), UL standards (United States), CE certification (European Union), etc., to ensure the product’s market access compliance in different countries or regions, while proving that the product’s performance and safety have been verified by authoritative institutions.