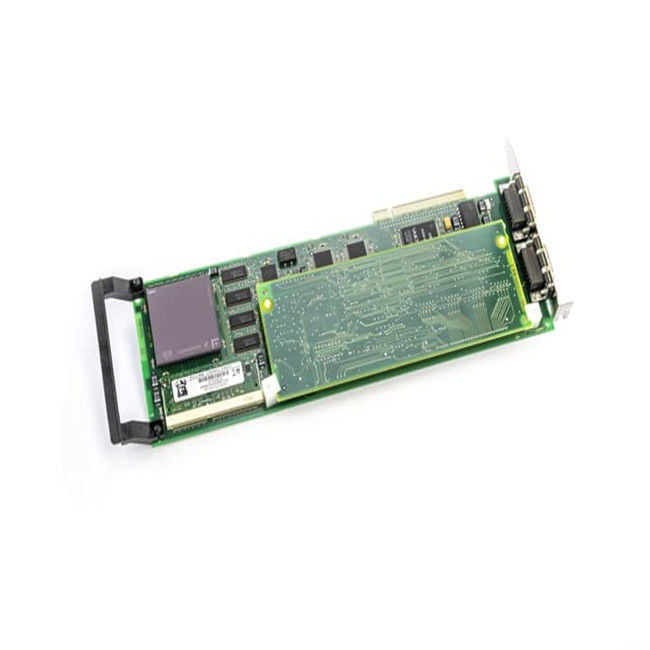

ABB 07KT97B Advant Controller 31 Intelligent Decentralized

User program: 480 kB

User data: 256 kB (Flash EPROM)

Digital inputs: 24 in 3 groups of 8 each, electrically isolated

Digital outputs:16 transistor outputs in 2 groups of 8 each, electrically isolated

Digital inputs/outputs: 8 in 1 group, electrically isolated

Analog inputs:8 in 1 group, individually configurable to 0…10 V, 0…5 V, +10 V, +5 V, 0…20 mA,4…20 mA, Pt100 (2-wire or 3-wire), differential inputs, digital inputs

Analog outputs: 4 in 1 group, individually configurable to 0…10 V, 0…20 mA, 4…20 mA

Serial interfaces: COM1, COM 2 as MODBUS interfaces and for programming and test functions

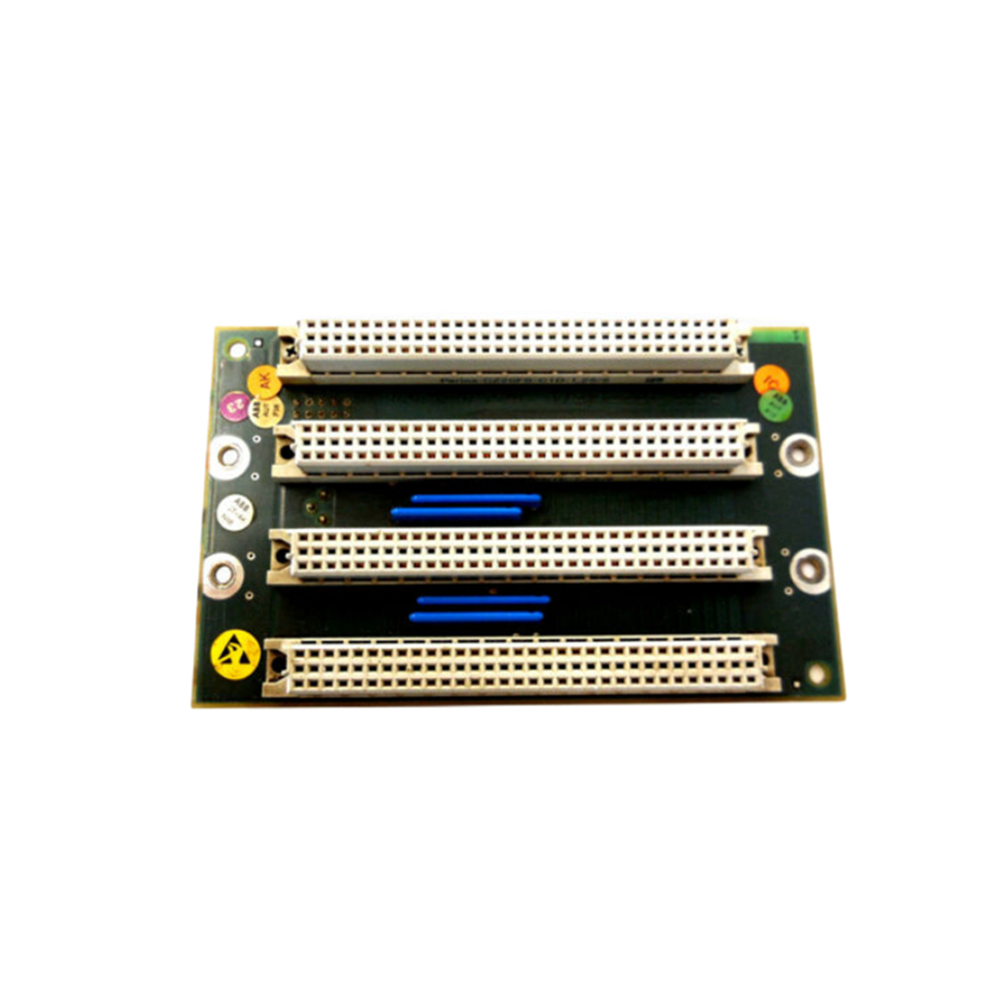

Parallel interfaces for connection of couplers:07 KP 90 (RCOM), 07 KP 93 (2 x MODBUS), 07 MK 92 (freely programmable)

System bus interface: CS31

Integrated couplers:see next page

High-speed counter: integrated, many functions configurable

Real-time clock: integrated

SmartMedia Card: memory medium for operating system, user program and user data

LED displays:for signal conditions, operating statuses and error messages

Power supply voltage:24 V DC

Data backup: with lithium battery 07 LE 90

Programming software: 907 AC 1131

Brief description

The basic unit 07 KT 97 works either as bus master in the decentralized automation system

Advant Controller 31 or as slave (remote processor) in the decentralized automa

tion system Advant Controller 31 or as stand-alone basic unit.

The basic unit is powered by 24 V DC.

Main features

digital inputs with LED displays

16 digital transistor outputs with LED displays

8 digital inputs/outputs with LED displays

8 individually configurable analog inputs 0…10 V,

0…5 V, ±10 V, ±5 V, 0…20 mA, 4…20 mA, differential inputs,

Pt100 (2-wire or 3-wire), the analog inputs are also individually configurable as

digital inputs

4 individually configurable analog outputs ±10 V,0…20 mA, 4…20 mA

2 counters for counting frequencies up to 50 kHz, con figurable in 7 different operating modes

1 CS31 system bus interface for system expansion

1 interface for connecting communication modules (e.g. 07 KP 90)

2 serial interfaces COM1, COM2– as MODBUS interfaces and– for programming and

test functions

Real-time clock

LEDs for displaying operating conditions and error messages

Detachable screw-type terminal blocks

Fastening by screws or by snapping the device onto a DIN rail

The lithium battery 07 LE 90 can be put into the

battery compartment in order to– store and backup the user program in the RAM– store and backup data which is additionally con

tained in the RAM, e.g. the status of flags– backup the time and date (real-time clock)

RUN/STOP switch for starting and aborting the pro gram execution

Extensive diagnosis functions– self-diagnosis of the basic unit– diagnosis of the CS31 system bus and the connected modules 2 07 KT 97 / Brief description

Exchangeable SmartMedia Card 07 MC 90 for user data or for updating the operating system or PLC pro gram

Project planning / start-up

The following has to be observed for project planning and start-up:

Programming is performed with AC31 programming software, which can be run on commercially available IBM compatible PCs (see documentation of the programming system 907 AC 1131).

Online program modification A quick modification of the user program is possible without interrupting the operation (see programming system 907 AC 1131).

Possible operating modes– Stand-alone basic unit– Bus master basic unit– Slave basic unit

Backup of data areas,i.e. saving of data during power OFF/ON, is possible with an integrated battery and/or by storing them in the Flash EPROM.

Specification

Model: 07KT97B Advant Controller 31

System type: intelligent decentralised automation system, based on modular design, can flexibly build industrial control network.

Processing power: Equipped with a high-performance processor with powerful data processing and logic operation capability, it can achieve millisecond response speed to meet the needs of complex industrial control scenarios.

Memory Configuration: Built-in high-capacity memory, supporting programme storage and real-time data caching, ensuring smooth system operation and handling a large number of control instructions and data interaction.

Communication interfaces: support a variety of communication protocols, including Profibus, Modbus, etc., equipped with Ethernet interface (10/100Mbps), RS-485 serial communication interface, easy to transfer and integrate data with various types of equipment, sensors and host computer systems.

I/O Module: It can be expanded with various types of I/O modules, such as analogue input/output module and digital input/output module, to meet the needs of signal acquisition and control in different industrial sites, and supports the expansion of [X] I/O channels at most.

Operating voltage: 24VDC ±10%, support redundant power supply modules to ensure the stability of system power supply.

Operating temperature: -20℃ – +60℃, adapt to different industrial environment temperature changes; relative humidity 5% – 95% (non-condensing).

Certification: CE, UL and other international certification, in line with industrial safety and quality standards.