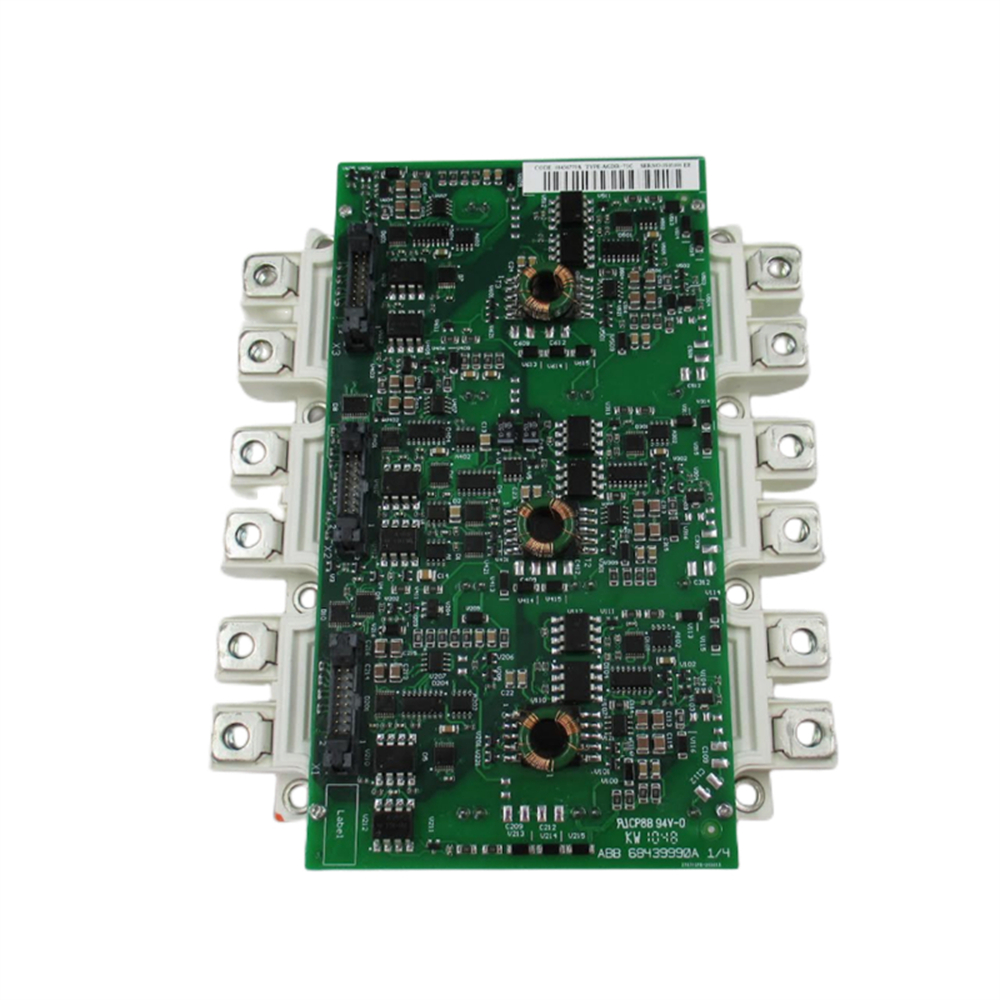

Alstom LC105A-1 Industrial Control Module

Product Overview

Alstom LC105A-1 Industrial Control Module is a high-performance industrial control module launched by Alstom, dedicated to providing stable and reliable control and monitoring solutions for industrial automation systems. This module integrates multiple functional modules into one through highly integrated design, with powerful data processing, logic control, and communication capabilities. It can be widely used in multiple fields such as power, manufacturing, and energy management, and is an important component to ensure efficient and stable operation of industrial production.

Specification parameters

Input/output interface: Equipped with rich input/output interfaces and multiple analog input channels, it can accurately collect analog signals such as voltage, current, temperature, pressure, etc., with a sampling accuracy of ± 0.15%; At the same time, it has sufficient digital input/output channels, supports standard level signals, can quickly respond to external device status changes, and output precise control commands. In addition, there are dedicated communication interfaces such as RS-485 and Ethernet interfaces to meet the data exchange and networking needs with different devices and systems.

Working voltage: Supports a wide voltage input of 18-36V DC, with a built-in high-efficiency voltage regulator circuit, which can work stably in industrial sites with large voltage fluctuations, ensuring the stability and reliability of module operation.

Working temperature: The working temperature range is -40 ℃ to 80 ℃, which can adapt to harsh industrial environments such as severe cold and high temperature. Whether it is outdoor power facilities or high-temperature production workshops, it can maintain stable performance.

Data processing capability: Equipped with high-performance processors, it has powerful data processing and computing capabilities, with a data processing speed of over 100000 times per second. It can perform real-time filtering, analysis, conversion and other processing operations on collected data, providing timely and accurate data support for system control.

Size specifications: Adopting a compact modular design, the size is approximately [specific length x width x height dimensions], occupying small space and making it easy to install inside various control cabinets or devices with limited space.

Core functions

Data collection and processing: It can collect various signals in the industrial production process in real time, and preprocess the collected data, including filtering and denoising, range conversion, linearization processing, etc., effectively improving data quality and usability. By using built-in algorithms for deep analysis of data, signal peak detection, trend prediction, and other functions can be achieved, providing powerful basis for system control decisions.

Precise logic control: Based on preset control logic and algorithms, precise control of external devices is achieved. In the power system, transformer tap changer and circuit breaker opening and closing can be automatically adjusted according to changes in grid parameters; In industrial automation production lines, precise control of motor start stop, speed adjustment, and the execution of robotic arm actions can be achieved to achieve automated and intelligent operation of equipment.

Efficient communication networking: With the help of RS-485, Ethernet and other communication interfaces, it supports multiple communication protocols such as Modbus RTU, Modbus TCP, Profibus, etc., and can achieve interconnection and intercommunication with different brands, types of devices and upper computers. Through network communication, the collected data can be uploaded in real time to the monitoring center and control instructions issued by the monitoring center can be received, achieving remote monitoring and control.

Intelligent fault diagnosis and protection: Equipped with a comprehensive fault diagnosis system, it can monitor its own working status and external device connection in real time. When abnormal situations such as input signal exceeding the range, communication interruption, and module high temperature are detected, an alarm signal is immediately issued, and protective measures such as cutting off output and entering safe working mode are automatically taken to prevent the fault from expanding and ensure the safe operation of the system.

Working principle

When the Alstom LC105A-1 Industrial Control Module is working, the analog signals output by external sensors or devices are connected to the module through the analog input channel. The signal is first amplified, filtered, and processed by the signal conditioning circuit, and then converted into digital signals through an analog-to-digital converter (ADC), which is transmitted to the built-in processor. The digital input signal directly enters the processor through the digital input interface. The processor performs logical operations and processes on input data based on programs and algorithms pre stored in internal memory, generating corresponding control instructions. These instructions are converted into analog signals through digital output channels or digital to analog converters (DACs), and then output to external actuators to achieve precise control of the device.

During the communication process, the communication interface module is responsible for transmitting and receiving data with external devices. When receiving data, decode and verify the signal before passing it to the processor; When sending data, encode and package the data processed by the processor, and send it out through a communication interface. At the same time, the clock circuit and power management circuit inside the module provide stable clock signals and power supply for the entire system, ensuring that all functional modules work together normally.

Key advantages

High precision and high reliability: Advanced sensor technology and high-precision A/D and D/A converters are used to ensure high precision in data acquisition and control. High quality electronic components are selected and rigorously tested to demonstrate excellent resistance to electromagnetic interference and environmental adaptability. They can operate stably even in complex electromagnetic environments and harsh weather conditions, significantly reducing equipment failure rates and maintenance costs.

Flexible scalability: Rich input and output interfaces and support for multiple communication protocols enable it to flexibly adapt to different industrial equipment and system requirements. Users can easily achieve functional expansion and system upgrades by adding expansion modules or adjusting software configurations according to actual application scenarios, meeting the changing needs of enterprise production development.

Efficient processing performance: The combination of high-performance processors and optimized data processing algorithms ensures that the module processes large amounts of data quickly and accurately, responds to external signal changes in a timely manner, makes control decisions quickly, and significantly improves system operating efficiency and production efficiency.

Convenient installation and maintenance: The compact modular design and standardized interface make module installation easy and can be quickly integrated into existing systems. The comprehensive self diagnostic function and clear fault indication facilitate technicians to quickly troubleshoot and repair faults, shorten equipment downtime, and improve production continuity.

Precautions

Installation environment requirements: It should be installed in a dry, well ventilated, non corrosive gas, and non violent vibration environment. Avoid installation in high temperature, humid, and dusty areas to prevent electronic components from being affected by moisture, oxidation, or dust blockage, which can affect performance and lifespan. The installation location should be far away from strong electromagnetic interference sources such as large motors and transformers to reduce the impact of electromagnetic interference.

Power connection specification: Before connecting the power supply, it is necessary to confirm that the input power supply voltage is consistent with the module requirements and ensure that the power supply polarity is correct. It is recommended to use a stable power supply and install appropriate fuses and filtering devices in the power line to prevent power fluctuations and surges from damaging the module.

Key points for signal connection: When connecting input and output signal cables, ensure that the cables are firmly connected to avoid virtual connections and short circuits. For analog signals, shielded cables are used and the shielding layer is reliably grounded to reduce external interference. At the same time, pay attention to matching the signal range to prevent the input signal from exceeding the range and damaging the module.

Software operation specifications: When configuring and programming software, strictly follow the product manual to avoid system failures or data loss caused by improper operation. Regularly backup module software for quick system recovery in case of failure. Before upgrading software versions, conduct testing to ensure compatibility between the new version of software and hardware.

Similar model supplement

Alstom LC106A-1 Industrial Control Module: It belongs to the same series as LC105A-1 and has similar basic functions and interface layouts. However, LC106A-1 has a significant improvement in data processing speed, with data processing speed 30% faster than LC105A-1, and supports more communication protocols. It is suitable for complex industrial control systems with higher requirements for data processing speed and communication compatibility.

Alstom LC104A-1 Industrial Control Module: This model focuses on digital signal processing. Compared to LC105A-1, it has increased the number of digital input/output channels by 40% and has more powerful logic operation functions. It is suitable for industrial scenarios mainly based on digital signal control, such as automated production line logic control and power system switch monitoring and control. However, its analog signal processing capability is relatively weak.

Application scenarios

Power system: Used for real-time monitoring and control of the operating status of power equipment such as generators, transformers, and circuit breakers in power plants, substations, and other electrical facilities. By collecting parameters such as device voltage, current, and temperature, data analysis and processing are carried out to achieve fault diagnosis, protection control, and optimized operation of the power system, ensuring the safety and stability of power supply.

Industrial automation production line: widely used in industries such as automobile manufacturing, electronic equipment manufacturing, mechanical processing, etc. Responsible for coordinating and controlling the operation rhythm and actions of various equipment on the production line, such as controlling the robot arm to grasp and place, conveyor belt start stop speed regulation, processing equipment parameter settings, etc. Through communication and networking with other equipment and control systems, achieve production line automation and intelligence, improve production efficiency and product quality.

Energy management system: In industrial enterprise energy management, it is used to collect energy consumption data of energy consuming equipment such as motors, boilers, air conditioners, etc., such as electricity, water, gas, etc. Through data analysis and processing, real-time monitoring, statistical analysis, and optimization control of energy consumption can be achieved, helping enterprises understand energy usage, formulate energy-saving measures, and reduce energy costs.

Process control system: In process industries such as chemical, pharmaceutical, and food processing, it precisely controls and monitors process parameters such as temperature, pressure, flow rate, and liquid level in the production process. According to the preset process requirements, automatically adjust the valve opening, pump speed and other actuators to ensure stable production process, meet product quality standards, and promptly handle abnormal situations during production to ensure production safety.