ABB INIIT03 Interface Modules

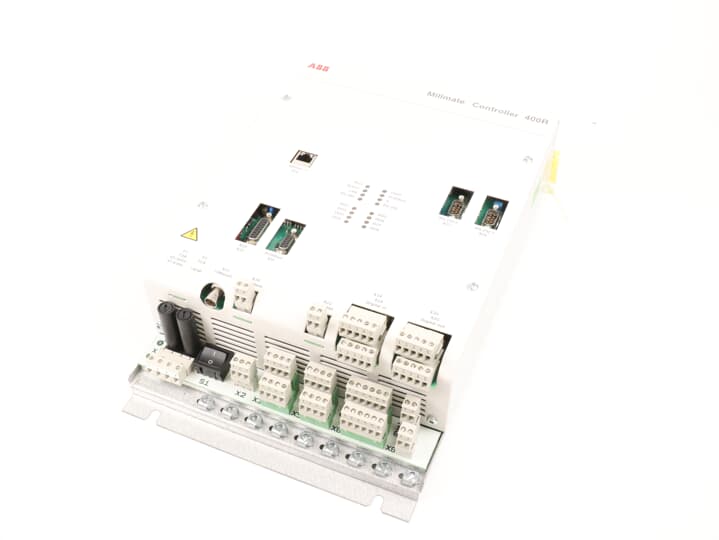

Product Overview

The ABB INIIT03 interface module is a key equipment designed specifically for industrial automation control systems, responsible for the core tasks of data transmission and protocol conversion in the system. It can efficiently connect different types of devices and systems, break down communication barriers, achieve seamless communication and collaborative work between devices, and is an essential component in building complex industrial automation networks. This module adopts a compact design, which is easy to install in various control cabinets and has excellent environmental adaptability, allowing it to operate stably in harsh industrial environments.

Specification parameters

Communication Interface: Equipped with multiple communication interfaces such as Ethernet interface and serial communication interface (RS232/RS485), supporting common industrial communication protocols such as Modbus TCP, Modbus RTU, Profibus DP, etc., it can flexibly adapt to the communication needs of different devices.

Working voltage: Supports 24VDC power supply, adapts to the power supply standards of most industrial sites, and ensures stable operation of the module.

Data transmission rate: The maximum data transmission rate of Ethernet interface can reach 100Mbps, and the speed range of serial communication interface is 9.6Kbps -115.2Kbps, which can meet the data transmission requirements in different scenarios.

Working temperature: The working temperature range is -40 ℃ -+70 ℃, suitable for extreme industrial environments such as high and low temperatures; The relative humidity range is 5% -95% (without condensation), effectively addressing the challenges of humid environments.

Protection level: It has an IP20 protection level and can prevent solid foreign objects with a diameter greater than 12mm from entering, while providing a certain degree of dust protection.

Core functions

Protocol conversion: One of the core functions of the INIIT03 interface module is to achieve the conversion between different communication protocols. For example, device data based on Modbus RTU protocol can be converted to Modbus TCP protocol for communication with the upper computer system, enabling devices of different protocols to work together in the same network and solve the compatibility problem of device communication in industrial automation systems.

Data transmission and processing: Able to quickly and accurately transmit device data, and perform necessary processing and optimization on the data. During the data transmission process, the module will verify and correct the data to ensure its integrity and accuracy, providing reliable data support for the control system.

Device connection and management: Multiple different types of devices can be connected simultaneously to achieve centralized management and monitoring of devices. Through the module, users can easily configure device parameters, read device status information, and improve device management efficiency.

Remote monitoring and diagnosis: Supports remote monitoring function, allowing users to remotely obtain module operation status information, fault alarm information, etc. through the network. At the same time, the module has self diagnostic function, which can quickly locate the fault point, facilitate remote troubleshooting and maintenance by technical personnel, and reduce maintenance costs and downtime.

Working principle

When the INIIT03 interface module is working, it first receives communication signals from different devices through its own communication interface. For example, after receiving data signals from sensors using Modbus RTU protocol, the protocol processing unit inside the module parses the signals and extracts valid data information. Then, according to the preset configuration and conversion rules, the protocol processing unit converts the data into the target protocol format, such as Modbus TCP format. The converted signal is sent to the target device or system through the corresponding communication interface, such as to the upper computer monitoring system. During the entire process of data transmission and conversion, the data processing unit will verify and process the data to ensure its accuracy and reliability. At the same time, the status monitoring unit of the module monitors its own operating status in real time. Once any abnormalities are detected, it immediately sends fault alarm information to the upper computer through the communication interface.

Key advantages

High compatibility: Supports multiple communication protocols and interface types, enabling seamless connection with the vast majority of industrial equipment on the market, greatly improving the flexibility and convenience of system integration, and reducing the difficulty of device selection and system integration for users.

Reliable stability: Using high-quality electronic components and advanced manufacturing processes, the module undergoes rigorous testing and verification to ensure long-term stable operation in harsh industrial environments. The strong anti-interference ability and perfect fault protection mechanism effectively ensure the reliability of data transmission and the stability of the system.

Flexible Scalability: The module design has good scalability, allowing users to flexibly increase or decrease the number of connected devices according to actual needs, facilitating system upgrades and modifications. At the same time, it supports multiple configuration methods, and users can easily configure parameters and adjust functions of the module through software tools.

Efficient and convenient: The high-speed data transmission capability and fast protocol conversion speed can meet the real-time requirements of industrial automation systems. The simple and easy-to-use interface and detailed user manual reduce the learning cost and difficulty of users, and improve work efficiency.

Precautions

Installation requirements: During installation, ensure that the module is securely installed to avoid loose connections caused by vibration. At the same time, it is necessary to ensure that the installation environment is dry, well ventilated, and away from strong electromagnetic interference sources. The environmental temperature and humidity of the installation location should be within the working range specified by the module.

Wiring specifications: Strictly follow the product manual for wiring operations to ensure correct and error free power and communication wiring. Different types of signal lines should be wired separately to avoid signal interference. After the wiring is completed, it is necessary to carefully check whether the wiring is secure to prevent poor contact from affecting the normal operation of the module.

Parameter configuration: Before use, it is necessary to correctly configure module parameters according to the actual application scenario, including communication protocol, baud rate, device address, etc. Incorrect parameter configuration may result in module communication failure or data transmission errors. Testing and verification should be conducted after the configuration is completed.

Maintenance: Regularly inspect and maintain the module, clean the surface dust of the module, and check whether the connecting cables are damaged. If the module malfunctions, the fault alarm information should be checked first, and the troubleshooting guide should be followed for handling. Non professionals are not allowed to disassemble the module without authorization.

Similar model supplement

ABB INIIT02 interface module: Compared with INIIT03, INIIT02 has slight differences in communication interface types and protocol support. It supports relatively fewer types of communication protocols and has a slightly lower data transmission rate. Suitable for industrial automation scenarios with low communication function requirements and small system scale, such as local equipment control networks in small factories.

ABB INIIT04 interface module: This model has been upgraded in terms of functionality, adding more communication interfaces and protocol support types, and significantly improving data processing capabilities and transmission rates. Suitable for large and complex industrial automation systems, such as automation control systems in large chemical plants and steel plants, it can meet the high-speed communication and data processing needs of a large number of equipment.