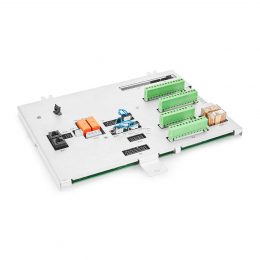

ABB 3HAC5497-1 Industrial Control Module

Product Overview

The ABB 3HAC5497-1 industrial control module is a high-performance control core equipment designed specifically for complex industrial automation scenarios. In the industrial production process, it is like the “nerve center” of the entire automation system, undertaking key tasks such as data processing, logical operations, and equipment coordination and control. By accurately analyzing signals collected by various sensors and generating control instructions based on preset programs and algorithms, the actuators are driven to complete corresponding actions, ensuring efficient, stable, and precise operation of industrial production. It is widely used in automation upgrading and transformation projects in multiple fields such as manufacturing, energy, and transportation.

Specification parameters

working voltage

Supports 24V DC wide voltage input, adapts to voltage fluctuations within a certain range, and ensures stable operation in complex industrial power supply environments.

Data processing capability

Equipped with Ethernet interfaces (supporting Profinet, Ethernet/IP protocols), RS-485 interfaces, CAN bus interfaces, etc., to achieve seamless communication with various devices and systems.

Input/output channel

It has 16 digital input channels, 12 digital output channels, 8 analog input channels, and 4 analog output channels to meet diverse industrial control needs.

Working temperature range

-From 20 ℃ to+60 ℃, it can work continuously and stably in harsh industrial environments such as high and low temperatures.

protection grade

IP20, Capable of basic dust prevention, preventing objects with a diameter greater than 12mm from entering and providing effective protection for internal circuits.

Certification standards

Through international authoritative certifications such as CE and UL, it complies with global industrial safety and quality standards, ensuring product reliability and safety.

Core functions

Precision control: Equipped with advanced PID control, fuzzy control and other algorithms, it can achieve high-precision adjustment of industrial equipment parameters such as motor speed, valve opening, temperature, pressure, etc. The control accuracy can reach ± 0.1%, meeting the extremely high requirements for control accuracy in industrial production processes.

Multi device collaborative control: Through rich communication interfaces and strong protocol compatibility, multiple industrial devices can be connected and managed simultaneously, achieving collaborative operations between devices. For example, on an automated production line, the work sequence and rhythm of robotic arms, conveyor belts, detection equipment, etc. can be accurately coordinated to improve production efficiency and product quality.

Data collection and processing: Quickly and accurately collect real-time data from various sensors, and perform filtering, analysis, storage, and other processing. Trend analysis can be conducted on the collected data to provide data support for production process optimization and fault prediction, helping enterprises achieve intelligent production management.

Fault diagnosis and alarm: equipped with comprehensive self diagnosis function, real-time monitoring of the operation status of the module itself and connected devices. Once a fault is detected, such as communication interruption, abnormal input and output, equipment overload, etc., it can immediately trigger an audible and visual alarm, and send detailed fault information to the upper computer through the communication interface, making it convenient for technicians to quickly locate and troubleshoot the fault, reducing downtime.

Working principle

When the 3HAC5497-1 industrial control module is working, it first receives analog or digital signals from devices such as temperature sensors, pressure sensors, and position sensors through input channels. After the analog signal is converted into digital signal by the A/D converter, it is transmitted to the high-performance processor inside the module together with the direct input digital signal. The processor performs logical operations and analysis on these data based on pre written control programs and algorithms to determine the current state of the industrial production process. Then, based on the judgment results, corresponding control instructions are generated and sent to actuators such as motors, solenoid valves, and regulating valves through D/A converters (for analog outputs) or directly through digital output channels to drive the actuators to perform corresponding actions and achieve control of industrial equipment. At the same time, the communication module is responsible for data exchange with the upper computer monitoring system, other control modules or devices, uploading equipment operation data, and receiving control parameter adjustment instructions to ensure the coordinated operation of the entire industrial automation system. The fault diagnosis module continuously monitors the operating status of various parts of the system, and once any abnormalities are detected, immediately activates the alarm and fault handling mechanism.

Key advantages

High performance and reliability: Using high-quality electronic components and advanced manufacturing processes, it has undergone rigorous aging testing, high and low temperature testing, vibration testing, etc. It has excellent anti-interference ability and stability, with an average time between failures (MTBF) of over 100000 hours, and can operate reliably in harsh industrial environments for a long time.

Flexibility and Scalability: Modular design enables flexible configuration of input/output channels and functional modules according to actual application needs, facilitating system upgrades and modifications. Support hot swappable function, allowing for module replacement or addition without interrupting system operation, improving the convenience of system maintenance.

Intelligence and convenience: Supports multiple programming languages, such as ladder diagram, structured text, etc., making it convenient for engineers to write and debug programs. Provide an intuitive and user-friendly interface and configuration software, which can complete module parameter settings, program downloads, and operation monitoring through graphical operations, reducing the threshold for use and learning costs.

Good compatibility: Not only can it seamlessly integrate with other industrial equipment and control systems under ABB, but it can also be compatible with third-party brand equipment and systems, making it easy to build diversified industrial automation solutions and meet the personalized needs of different enterprises.

Precautions

Installation environment: During installation, a dry, well ventilated environment away from strong electromagnetic interference sources should be selected to avoid installation in places with high temperature, humidity, corrosive gases or dust. Ensure that the environmental temperature and humidity at the installation location are within the specified working range of the module.

Wiring specifications: Strictly follow the wiring diagram in the product manual for wiring operations, distinguish the positive and negative poles of the power supply, input and output signal lines, and avoid module damage or system failure caused by wrong wiring. Different types of signal lines should be wired separately to prevent signal interference; The grounding wire should be reliably grounded, and the grounding resistance should meet the requirements.

Parameter configuration: Before use, it is necessary to correctly set the communication protocol, baud rate, device address, input/output type and other parameters of the module through configuration software according to the actual industrial application scenario. After the parameter settings are completed, functional testing should be conducted to ensure that the module is working properly.

Regular maintenance: Regularly inspect the module, including visual inspection, wiring terminal tightening inspection, cooling fan operation status inspection, etc. Regularly clean the dust on the surface of the module to prevent dust accumulation from affecting heat dissipation and electrical performance. Perform performance calibration on the module at regular intervals to ensure control accuracy.

Similar model supplement

ABB 3HAC5497-2 Industrial Control Module: Compared with 3HAC5497-1, 3HAC5497-2 has adjusted the number of input/output channels, increasing the number of analog input channels and reducing the number of digital output channels. It is more suitable for industrial scenarios that require the collection of a large number of analog signals (such as temperature, pressure, flow, etc.), such as chemical production process monitoring, environmental monitoring systems, etc.

ABB 3HAC5498-1 Industrial Control Module: This model has been upgraded in terms of data processing capability and communication performance, equipped with a higher performance processor, faster data processing speed, and supports more industrial communication protocols and higher data transmission rates. It is suitable for large-scale industrial automation systems that require extremely high real-time and data processing requirements, such as central control systems for smart factories, large-scale power dispatch systems, etc.