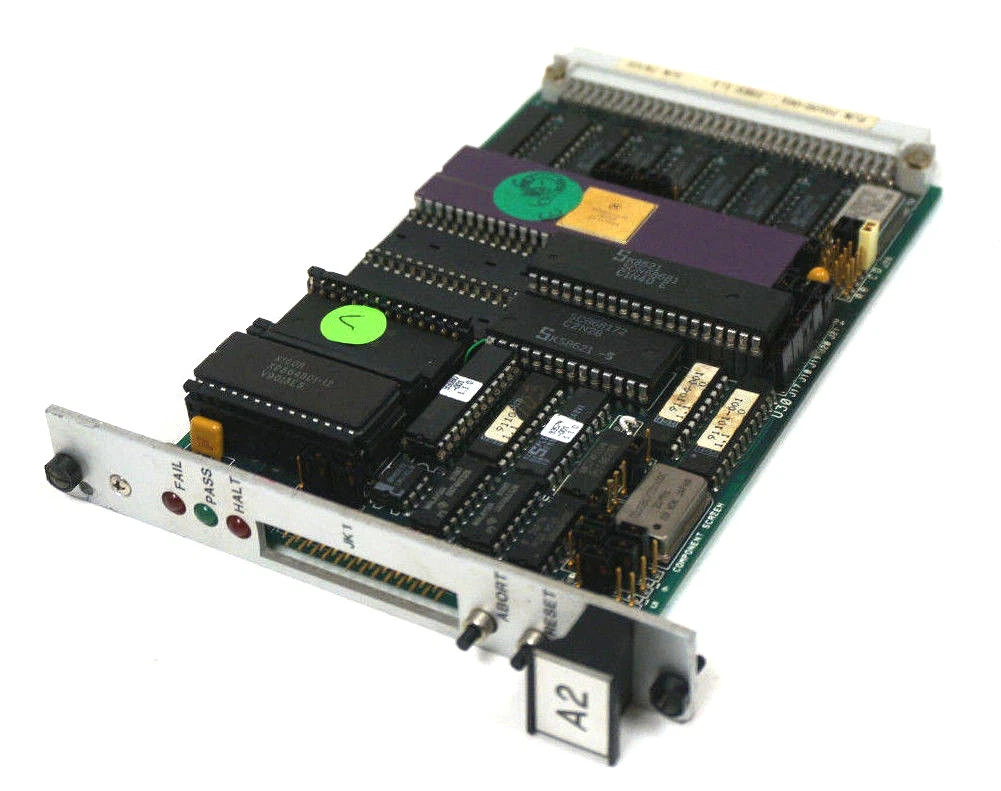

Xycom XVME-244 DIO Digital Input

Overview

The XVME-244 Digital I/O Module is an isolated 64-channel, digital I/O module designed for use in

VMEbus systems.

Thirty-two input channels and thirty-two output channels are provided, arranged in groups of eight, optically-isolated from the others and from the VMEbus circuitry.

The 64 I/O channels are arranged to form eight, byte wide I/O registers. The I/O registers are addressed consecutively, allowing the input and output channels to be accessed as either bytes or words.

To add to the integrity of the system, default initialization disables all outputs both during system power-up and during a software reset or SYSFAIL.

This module is ideally suited for interfacing to pushbutton or relay contacts.

It contains input debouncing circuitry which eliminates the effects of contact bounce from such inputs.

The XVME-244 provides four filtered inputs for those applications where filtering is desired for a particular input.

One filtered input is provided for each input group as a read-only register containing the state of

the filtered input.

These registers may be accessed as bytes or as 16-bit words.

Features

Outputs

• 32 optically-isolated digital output channels

• Outputs to 30 V and 400 mA

• 300 VDC optical isolation group-to-group and

1000 V group-to-VMEbus

• Hardware initialization of outputs at power-up

• Outputs are software-readable

• Transient protection on all outputs

Inputs

• 32 digital input channels

• Input voltage range 10-35 VDC

• Input debouncing circuitry

• 35 VDC reverse bias protection

• 300 VDC optical isolation group-to-group and

1000 V group-to-VMEbus

Applications

Outputs

• Control valves

• Solid-state relays

• Alarm interface

• Indicator lamps

Inputs

• Limit switches

• Push buttons or panel switches

• Proximity switches

• Alarm trips

• Photo detector switches

Product Overview

Xycom XVME-244 DIO Digital Input/Output Card Module 70244-001 is a digital input/output card module designed based on the VME Bus standard, specifically designed for industrial automation control, data acquisition, and monitoring systems. As a key component of signal interaction in industrial control systems, it can efficiently collect and output digital signals, accurately control various actuators, ensure the stable operation of industrial production processes, and is widely used in fields such as automotive manufacturing, electronic assembly, and energy management.

Brand background

Xycom has been deeply involved in the fields of industrial automation and embedded computing for many years, renowned for providing high-performance and highly reliable hardware products. With its profound technical accumulation and strict quality control, its products have gained wide recognition and trust in industries such as industry, aerospace, etc. that require extremely high stability and accuracy. Xycom continues to innovate and is committed to meeting the increasingly complex application needs of industrial customers, making it the preferred partner for many industrial enterprises.

Core functions

Digital signal acquisition: Quickly and accurately collect various digital signals from industrial sites, such as equipment start stop status, limit switch signals, sensor trigger signals, etc. Real time processing and caching of collected signals to provide accurate equipment operating status information for the control system, in order to make timely control decisions.

Digital signal output: According to the instructions of the control system, the digital signal is accurately output to the actuator to achieve on/off control of the equipment. For example, controlling the start and stop of motors, opening and closing of valves, and turning on and off indicator lights to ensure that industrial production processes proceed in an orderly manner according to preset logic.

Signal isolation and protection: Through optoelectronic isolation technology, input/output signals are effectively isolated from external circuits to prevent external electrical interference from affecting the module and control system. At the same time, it has overcurrent and short-circuit protection functions to enhance the reliability and durability of the module and extend the service life of the equipment.

Communication and Collaboration: Supports communication with other devices on the VME Bus bus, uploads collected digital signals to the main controller or upper computer, and receives control instructions from the main controller to achieve collaborative work with the entire industrial control system, ensuring consistency and stability of system operation.

Precautions

Installation environment: During installation, a dry, well ventilated, and dust-free environment should be selected to avoid installation in places with corrosive gases, large amounts of dust or water vapor, and to prevent electronic components from being corroded or damaged. At the same time, it is necessary to ensure that the installation location has good heat dissipation conditions to avoid affecting the performance and lifespan of the module due to high temperatures.

Wiring operation: When wiring the module, it is necessary to ensure that the equipment is in a power-off state and strictly follow the wiring diagram and instructions to avoid module damage or system failure caused by wiring errors. For input signals, it is necessary to ensure that the voltage level of the signal source matches the input requirements of the module; For output signals, attention should be paid to the rated voltage and current of the load to avoid overload.

Static protection: When installing, disassembling, or maintaining modules, operators must wear protective equipment such as anti-static wristbands to avoid damage to the precision electronic components on the module caused by human static electricity. During the operation, direct contact with electronic components and circuits should be avoided as much as possible.

Communication settings: When communicating with other devices on the VME Bus bus, ensure that the communication parameters of the module (such as address, baud rate, etc.) are consistent with other devices, otherwise it may cause communication failure. During system operation, if communication parameters need to be changed, the relevant equipment should be stopped before setting the parameters