KONGSBERG DPS132 positioning system host navigation ship

Technical principles and functional characteristics

High precision positioning mechanism

DPS132 is based on dual frequency GPS signals (L1 and L2 frequency bands), combined with satellite based augmentation systems (SBAS, such as WAAS, EGNOS) and wide area differential correction technology, which can improve positioning accuracy to sub meter level. The system has a built-in lever arm compensation function, which can accurately calculate the positions of multiple measurement points on the ship by integrating the ship’s heading information, meeting the needs of multi-sensor fusion.

Redundancy Design and Reliability

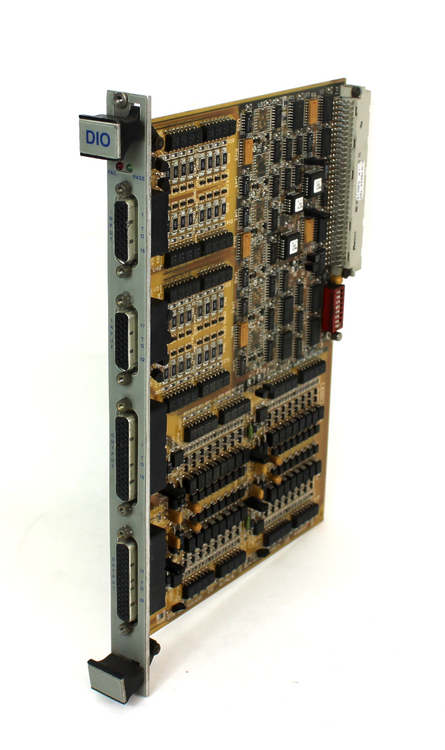

The system adopts a two-level redundant control architecture with a fail safe mechanism, which can automatically switch to backup modules when critical components fail, ensuring the continuity of positioning function. Its hardware design meets the high reliability requirements of maritime environments, supports Windows NT4.0 operating system, and has long-term stable operation capability.

Multi mode operation capability

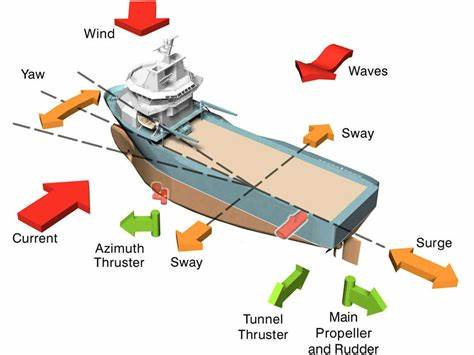

DPS mode: By processing real-time data from sensors such as GPS, gyro compass, sonar, etc., the thruster thrust is dynamically adjusted to counteract external forces such as wind, waves, and currents, enabling the ship to hover at a fixed point or navigate along a preset path.

Navigation mode: Used as a conventional navigation system, it provides basic position, speed, and heading information.

Data visualization and user interface

DPS132 can be integrated with KONGSBERG’s K-Master comprehensive bridge system, displaying ship status, sensor data, and environmental parameters through a unified graphical interface (such as touch screen), and supporting linkage control with ECDIS, radar, autopilot, and other equipment.

Application scenarios and industry value

Marine engineering operations

In tasks such as deepwater drilling and submarine cable laying, DPS332 can ensure that ships maintain a stable position without anchoring conditions, such as controlling system errors within 0.3 meters in Class II sea conditions. Its precise positioning ability significantly improves operational efficiency and reduces the time and cost consumption of traditional anchoring methods.

Scientific expedition and deep-sea exploration

Research vessels such as the “Exploration 2” are equipped with a DP2 level dynamic positioning system (similar to DPS132 technology), which can support the deployment and recovery of manned submersibles and precise operation of deep-sea observation equipment in complex sea conditions. The low noise characteristics of DPS332 (electric propulsion design) can also provide a stable working environment for underwater acoustic equipment and improve data acquisition quality.

Port and narrow water operations

The automatic tracking and heading control functions of DPS332 can assist crew members in dealing with complex steering and obstacle avoidance needs in entering and exiting ports or congested waterways, reducing human operational risks.

Industry standards and certifications

Although specific certification information was not explicitly mentioned in the search results, KONGSBERG, as a global maritime technology leader, typically meets the Dynamic Positioning (DP) standards of the International Maritime Organization (IMO) (such as DP-2 or DP-3) and has been certified by authoritative organizations such as DNV GL. For example, the DP2 level system of “Exploration 2” reflects the practical application of KONGSBERG technology in the field of scientific research ships.

Core technical parameters

positioning accuracy

Horizontal accuracy: With the support of SBAS (Satellite Based Augmentation System), the typical value is * *<1 meter * * (RMS); Combined with wide area differential correction technology, it can be upgraded to sub meter level (0.3-0.5 meters).

Vertical accuracy: * *<2 meters * * in SBAS mode, and can be optimized to 1-1.5 meters in dual frequency GPS mode.

Dynamic response: The system delay is less than 100ms, meeting the real-time control requirements of the ship.

Navigation sensor compatibility

Support multi-sensor fusion: GPS (L1/L2 dual frequency), gyro compass, MRU (motion reference unit), sonar, etc.

Built in Lever Arm compensation function, which can access ship heading information and calculate the positions of multiple measurement points on board.

Differential correction support

Compatible with DGPS (Wide Area Differential), SBAS (such as WAAS, EGNOS), and UHF link differential (for offshore loading scenarios).

Physical and environmental parameters

Hardware configuration

Host unit: 4U standard rack mounted design, weighing approximately 15-20kg (referring to similar maritime equipment).

Interface type:

Communication interface: RS-422/485, Ethernet (supporting NMEA 0183/2000 protocol).

Sensor interfaces: gyro compass (such as KONGSBERG HUGIN), MRU, sonar (such as HIPAP 500).

Power requirements:

Input: 220-240V AC, 50/60Hz, power consumption * * ≤ 500W * * (including redundant modules).

Backup power supply: Supports DC 24V (optional UPS).

Environmental adaptability

Working temperature: -20 ° C to+55 ° C (compliant with maritime equipment standards).

Humidity: 5% -95% RH (non condensing).

Protection level: IP54 (dustproof and splash proof), in compliance with DNV GL maritime environmental certification.

Redundancy and reliability

System Architecture

Secondary redundancy: Main/backup controllers, power modules, and communication links, with a fault switching time of less than 200ms.

Data backup: Supports local storage (SSD) and remote log transfer.

Certification standards

Complies with the IMO MSC.86 (70) dynamic positioning standard and supports DP-2/DP-3 level applications (such as the configuration of the “Haiyang Shiyou 981” drilling platform).

Certified by DNV GL (specific model confirmation required, reference to similar products).

function characteristics

Multi mode operation

DPS mode: Real time dynamic positioning, supporting fixed-point hovering, path tracking, and automatic obstacle avoidance.

Navigation mode: Basic navigation information output (latitude and longitude, speed, heading).

Test mode: Sensor calibration and system diagnosis.

data output

Output frequency: 10Hz (configurable).

Data format: NMEA 0183/2000, KONGSBERG specific protocol (such as K-Bridge).

Application scenario parameters

Marine engineering operations

Under the second level sea conditions (wind speed of 12-19 knots, wave height of 1.25-2.5 meters), the position maintenance error is * * ≤ 0.5 meters * *.

Support deepwater operations (water depth>3000 meters), compatible with HIPAP sonar positioning system.

Scientific expedition and deep-sea exploration

Low noise design (compatible with electric propulsion), supporting stable operation of underwater acoustic equipment.

Integrate K-Master bridge system to achieve multi device linkage control.

Scalability

Communication Expansion

Support UHF wireless links (used for relative positioning between ships, such as loading scenarios at sea).

Can be connected to KONGSBERG Intelligent Awareness system (AI assisted navigation).

software upgrading

Support remote firmware updates and feature extensions (such as adding sensor protocols).

Industry application examples

The “Haiyang Shiyou 981” drilling platform is equipped with DPS132 and DPS200 dual redundant positioning systems, which meet the DP-3 level requirements and have a positioning accuracy of less than 0.5 meters.

The “Exploration 2” scientific research vessel adopts similar DP2 technology, supporting the deployment of manned submersibles and the operation of deep-sea observation equipment.