ABB RET 541/543/545 Transformer Terminal Device

Product positioning and core features

RET 541/543/545 is a protection, control, measurement, and monitoring device designed specifically for double winding transformers and generator transformer units in medium voltage distribution networks, suitable for harsh environments such as heavy industry, marine, and offshore. Its core advantages include:

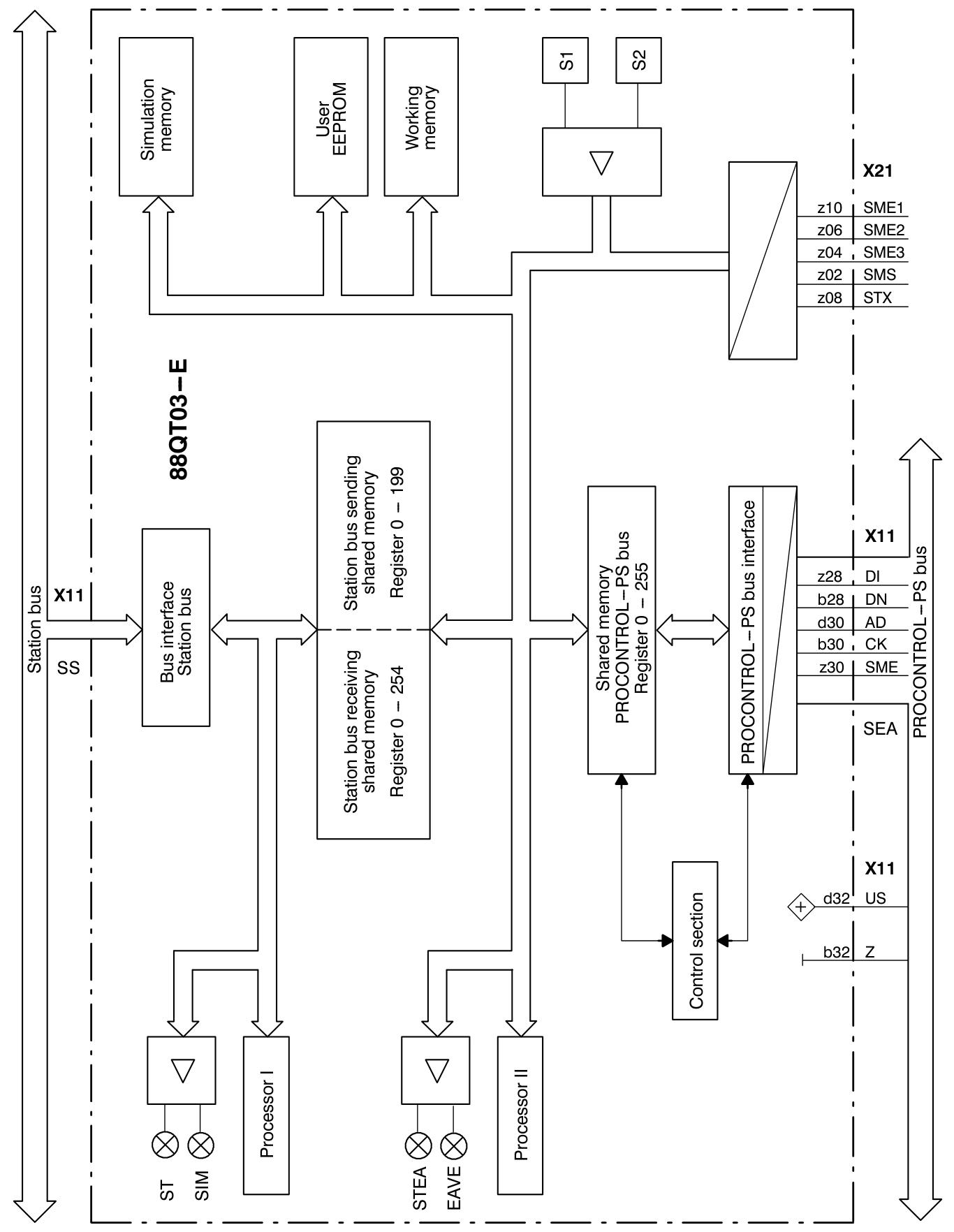

Modular design: Supports 1/2 × 19 inch chassis, can expand functions through RTD/analog modules, and adapt to the needs of substations of different scales.

High performance protection: Integrated stable differential protection, high/low impedance grounding protection, and multi-stage overcurrent protection, response time<50ms, supporting CT saturation adaptive.

Multi protocol communication: Built in SPA, LON, IEC 60870-5-103, Modbus, DNP 3.0 protocols, can be connected to Profibus DP or IEC 61850 systems through adapters.

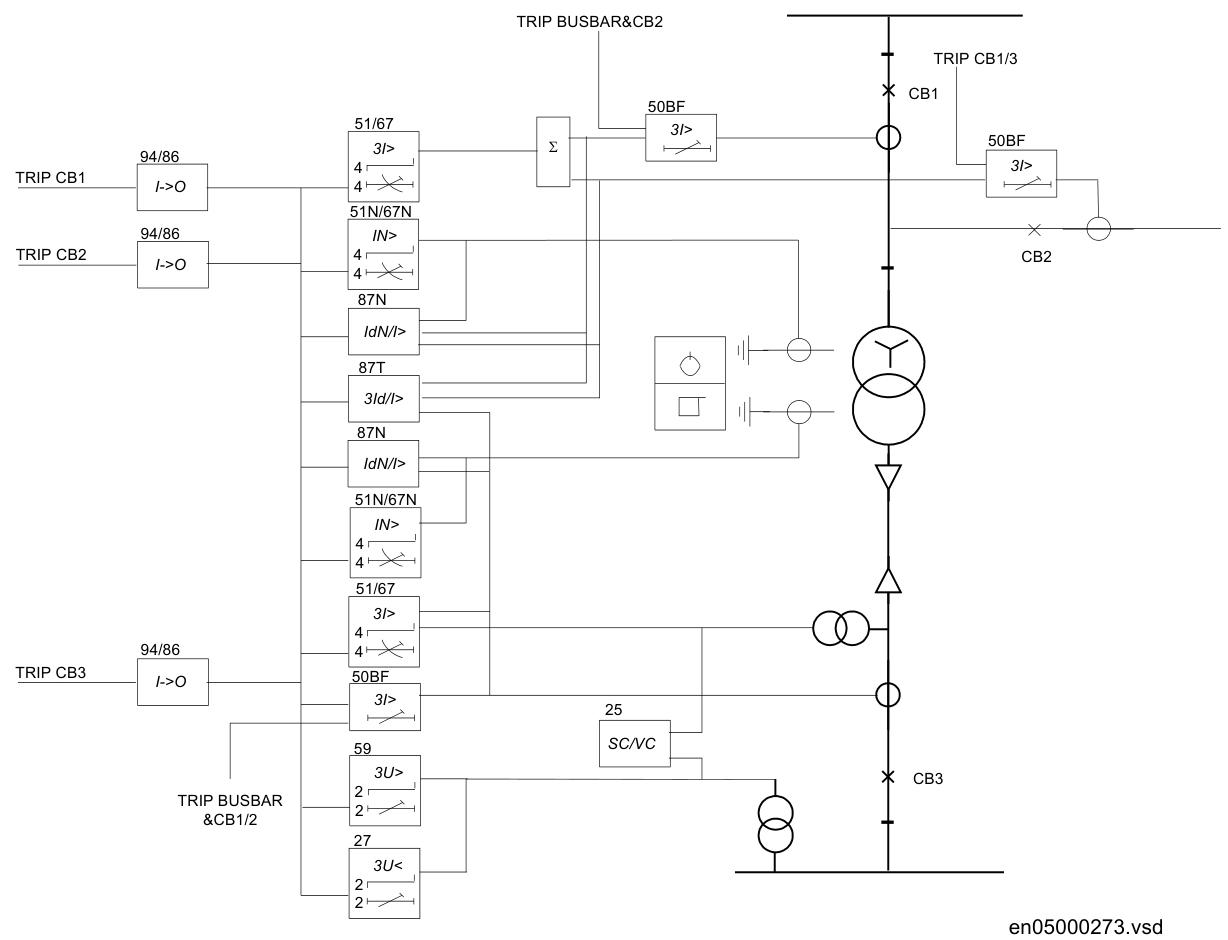

Core protection function

Differential and grounding protection

Three phase differential protection (87T): including second harmonic/fifth harmonic braking and waveform recognition locking, automatically matching transformer vector group, supporting zero sequence current elimination, preventing misoperation of faults outside the area.

High/Low Impedance Grounding Protection (REF): The high impedance principle does not require a stable resistor, while the low impedance principle supports CT variable ratio inconsistent scenarios, with a sensitivity of up to 5% of the rated current.

Overcurrent and backup protection

Multi stage overcurrent protection (51/50): supports definite time (DT) and inverse time (IDMT) characteristics, with three-stage low setting, two-stage high setting, and instantaneous period, with an action accuracy of ± 2.5%.

Directional overcurrent protection (67): Based on phase voltage/line voltage polarization, it supports forward/reverse action direction and has strong resistance to load intrusion.

Voltage and frequency protection

Overvoltage/undervoltage protection (59/27): three-stage phase voltage protection, residual voltage protection (59N) adapted to ground faults, action time<66ms.

Overexcitation protection (24): Based on U/f ratio monitoring, two-stage alarm/trip to prevent magnetic core saturation.

Auxiliary protection

Thermal overload protection (49T): Dual time constant model, real-time monitoring of winding temperature, supporting RTD input (such as Pt100).

Circuit breaker failure protection (62BF): When detecting refusal to move, quickly trip adjacent circuit breakers with a response time of less than 20ms.

Measurement and monitoring functions

real-time

Support three-phase current/voltage, sequence component, power, frequency, and harmonic analysis (suppression -50dB), with a measurement accuracy of ± 0.5%.

RTD/Analog Module: 8 inputs (6 RTDs+2 mA), used for oil temperature and gear monitoring; 4-channel 0-20mA output, compatible with PLC system.

Fault recording and recording

Disturbance Recorder (MEDREC16): 16 analog signals+16 switch signals, supporting COMTRADE format, with a maximum recording time of 23.3 seconds.

Event and fault records: 512 time stamped events, 32 fault records (including peak/phase angle), non-volatile storage.

Status monitoring

Circuit breaker monitoring: monitoring spring energy storage, SF pressure, travel time, and supporting life prediction.

Circuit monitoring: Continuous monitoring of the tripping circuit, detecting disconnection or poor contact, with a response time of less than 40ms.

Control and Communication

Local and remote control

The front panel supports circuit breaker opening and closing, isolation switch position indication, and can be configured with dynamic single line diagram (HMI).

Remote control supports GOOSE horizontal communication to achieve protection interlocking and status synchronization.

Communication interface and protocol

Serial interface: RS-232/485, supports Modbus RTU/ASCII, DNP 3.0, IEC 60870-5-103.

Ethernet interface: 100Base TX/FX, supports SPA, LON bus, and IEC 61850-8-1 GOOSE (transmission time<3ms).

Time synchronization: SNTP, IRIG-B, with a time scale accuracy of 1ms, ensuring consistency of events across the entire network.