ABB S800 I/O DTM 5.3 module

Basic Product Information

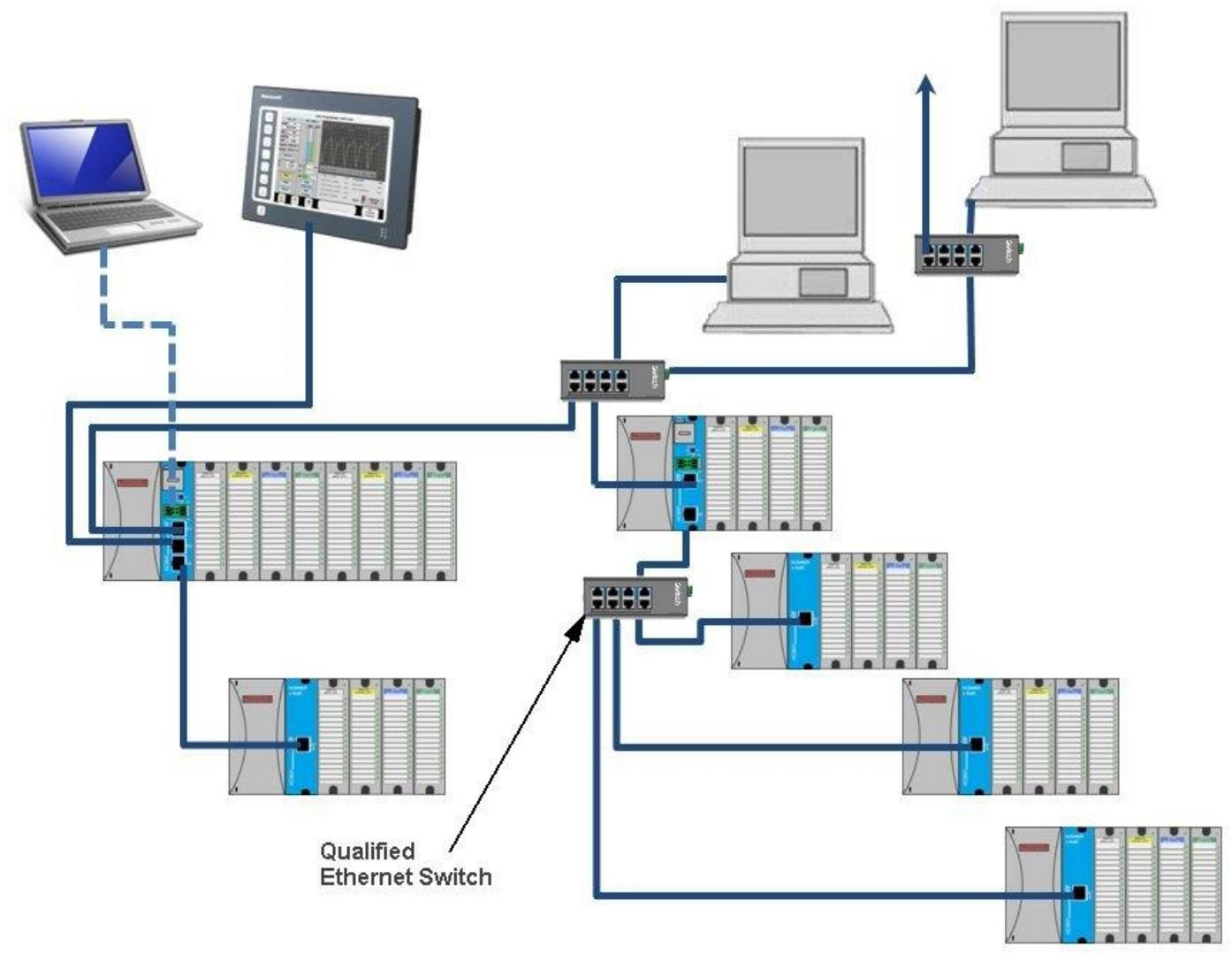

Product positioning: S800 I/O DTM 5.3 is a device type manager software component launched by ABB for S800 I/O modules, which complies with the FDT 1.2 specification and can be used in conjunction with framework applications that comply with this specification.

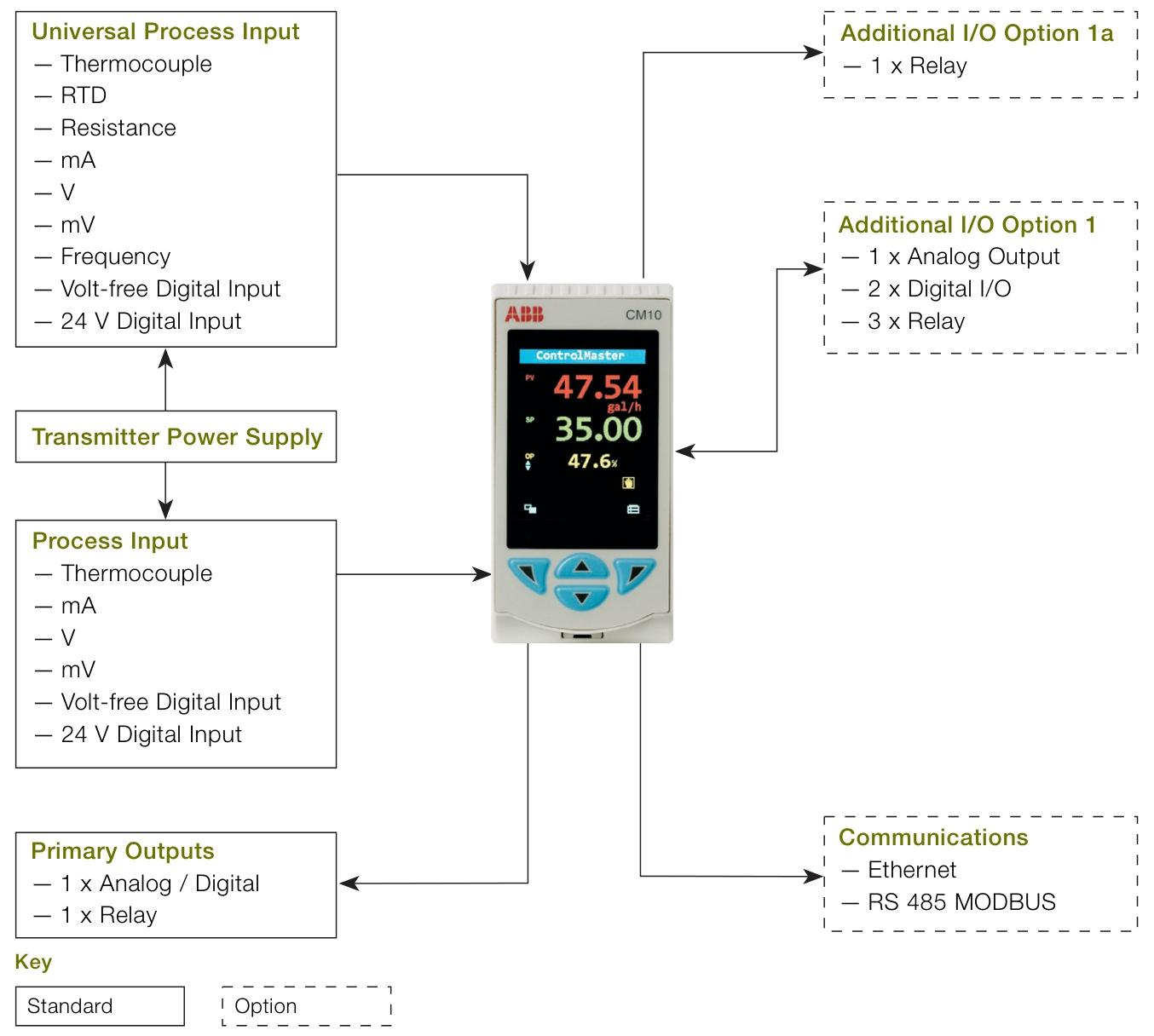

Support modules: covering various S800 I/O modules, including communication interface modules (such as CI801, CI840), analog input/output modules (such as AI801, AO801), digital input/output modules (such as DI801, DO801), and pulse counter modules (such as DP820, DP840).

Version and Release Information: The document version is 3BSE027630-510 A, released in February 2013, suitable for S800 I/O DTM 5.3 version, supporting 64 bit operating systems and 800xA 5.1 Feature Pack 3 scenarios.

Function characteristics

Core functions

Equipment configuration and diagnosis: Provide a graphical configuration interface for various types of S800 I/O modules, which can set parameters such as signal range, filtering time, redundancy mode, etc; Equipped with comprehensive diagnostic functions, it can display module status, channel errors, and diagnostic information related to HART devices.

Data collection and processing: It can collect analog and digital data in real time, process, display, and store them, and support dynamic data viewing and monitoring.

Communication and Interface: Supports multiple communication protocols (such as Modbus) and interfaces (Ethernet, serial port, CAN bus, etc.) to achieve data exchange with other devices and systems; Some modules support the HART protocol and can communicate with HART instruments.

Redundancy and security mechanism: Some modules support redundant configuration (such as CI840, AI845, etc.) to improve system reliability; Equipped with fault diagnosis and monitoring functions, it can monitor equipment status in real-time and issue alarms.

Featured Features

HART tool routing: supports HART DTM connection, enables configuration and monitoring of HART instruments, and can perform HART parameter settings, device scanning, and other operations.

Event Sequence (SOE): Some digital input modules (such as DI825, DI830, etc.) support SOE functionality and can record timestamps of digital input signals for fault analysis and event tracing.

Dynamic data monitoring: Provides real-time display of dynamic data from various modules, such as analog values, digital status, pulse counting, etc., supporting periodic reading and single update.

Installation and system requirements

System prerequisites

Operating system: Supports Windows Server 2008 (32/64 bit), Windows 7 (32/64 bit), etc.

Software dependencies: ABB FDT Shared Components 13.0.0.0 and ABB FDT Base Container 13.0.0.0 need to be installed. Remote I/O requires PROFIBUS master DTM, and HART functionality requires HART DTM (such as Basic HART DTM).

Installation process

Insert the installation CD, run Setup. exe, and follow the wizard to select the installation components.

You can choose to install locally or copy to the server, and support generating installation logs.

Maintenance and uninstallation: Maintenance operations can be performed through the control panel, including changing components, repairing programs, or uninstalling; During uninstallation, it is necessary to confirm and wait for the process to complete.

Operation and Handling

User Interface and Roles

Interface composition: including title bar, toolbar, application area, status bar, etc. Different applications (such as diagnosis, configuration, observation, etc.) have corresponding interface layouts.

User roles: divided into operators, maintenance personnel, planning engineers, etc., different roles have different access permissions to various application functions (such as read/write permissions).

Main application functions

About DTM: Display DTM version, release information, etc.

Identification: Display module hardware information, such as type, manufacturer, location, version, etc.

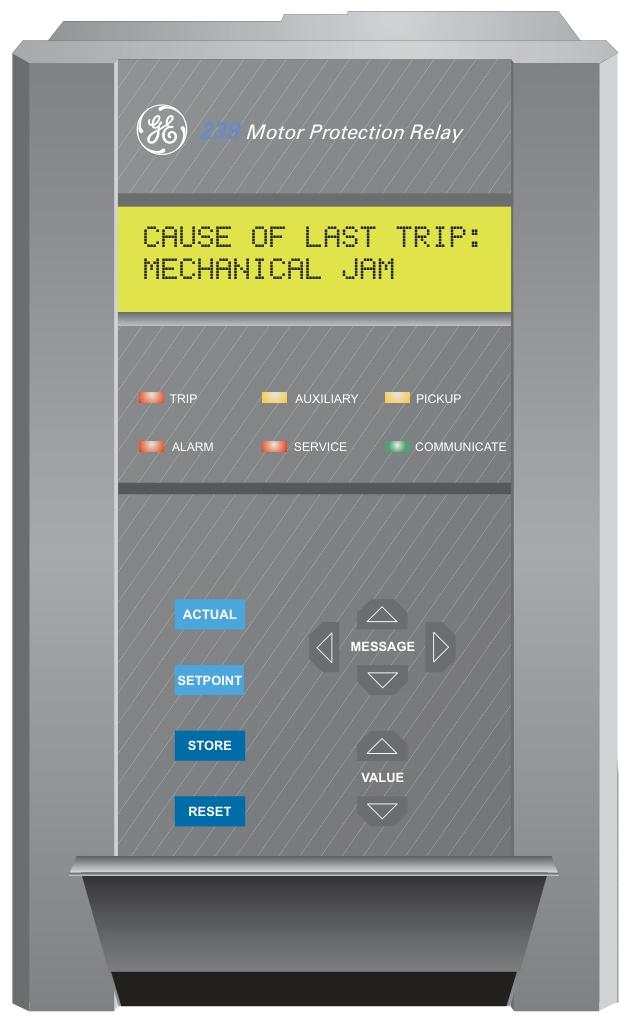

Diagnosis: Display module and channel diagnostic status, including error types, warning messages, etc.

Observe: Real time monitoring module for dynamic data, such as analog values and digital status, supporting periodic refreshing.

Configuration: Set module parameters such as signal range, filtering time, redundancy mode, OSP value, etc.

Parameterization: Set HART parameters for the HART module, such as retry count, scan status, etc.

Service: Execute special function commands, such as resetting modules, reading diagnostic history, switching redundant modules, etc.

Dynamic data: Each module defines pre dynamic data connections, such as station warnings and redundant power failure signals for CI801, analog values and channel states for AI801, digital values for DI801, etc. The data types include bytes, integers, Boolean values, etc.

Application area

Industrial automation: suitable for production line automation control, data acquisition and processing, equipment status monitoring and maintenance, etc. It can control equipment such as motors, valves, sensors, etc.

Railway transportation: used for train tracking and signal management, safety mechanism control, onboard system diagnosis and communication, etc., such as implementing PROFIBUS communication through CI801/CI840 modules.

Energy management: Monitoring and controlling equipment and systems involved in energy production, transmission, and distribution processes in industries such as electricity, oil, and natural gas.

Intelligent building: Centralize control and management of mechanical and electrical equipment (such as elevators, air conditioning, lighting systems) within the building to achieve intelligent operation and energy conservation.

Precautions and limitations

Compatibility: S800 I/O DTM 1.0/0 and higher versions do not support FDT 0.98 specification framework applications; Some module functionalities (such as SOE) are only supported in specific framework applications (such as AC870P/Composer).

Security and Permissions: Operations involve security measures (such as user access, password security, etc.), and users are required to conduct risk assessments and be responsible for the correct configuration, installation, and maintenance of related equipment and software.

HART function limitation: When the HART instrument is connected to modules such as AI895/AO895 during operation, it needs to manually perform “Perform master reset” to be detected; When the HART communication main module fails, manual switching is required.