WOODWARD PG-PL Governor Installation and Operation

Basic information of the document

Document type: PG-PL Governor Installation and Operation Manual

Manual Number: 36694 (Revision P)

Applicable product: Woodward PG-PL governor (used for speed control of engines, turbines, and other prime movers)

Core safety requirements

(1) Warning definition and protection principles

Danger (DANGER): Failure to avoid causing death or serious injury

Warning: Failure to avoid may result in death or serious injury

CAUTION: Failure to avoid may result in minor or moderate injury

Notice: May only cause property damage

Important: Operation tips or maintenance recommendations

(2) Key safety measures

The prime mover must be equipped with an overspeed shutdown device independent of the speed control system, and if necessary, an overtemperature/overpressure shutdown device must be installed

Wear appropriate PPE during operation, including goggles, hearing protection equipment, helmets, gloves, safety boots, respirators, etc

Be prepared for emergency shutdown when starting the prime mover to prevent loss of control or overspeed

Electrostatic protection: Release human static electricity before coming into contact with electronic controls, avoid using non anti-static plastic/vinyl materials, and do not touch printed circuit board components

(3) Special scenario security

Automotive application: A monitoring device independent of the speed control system needs to be installed (if Woodward control is a monitoring control)

Battery charging device: Before disconnecting the battery, the charging device must be turned off

Solvent usage: Operate in a well ventilated area, away from sources of ignition, and follow the manufacturer’s instructions

Installation and commissioning specifications

(1) Installation requirements

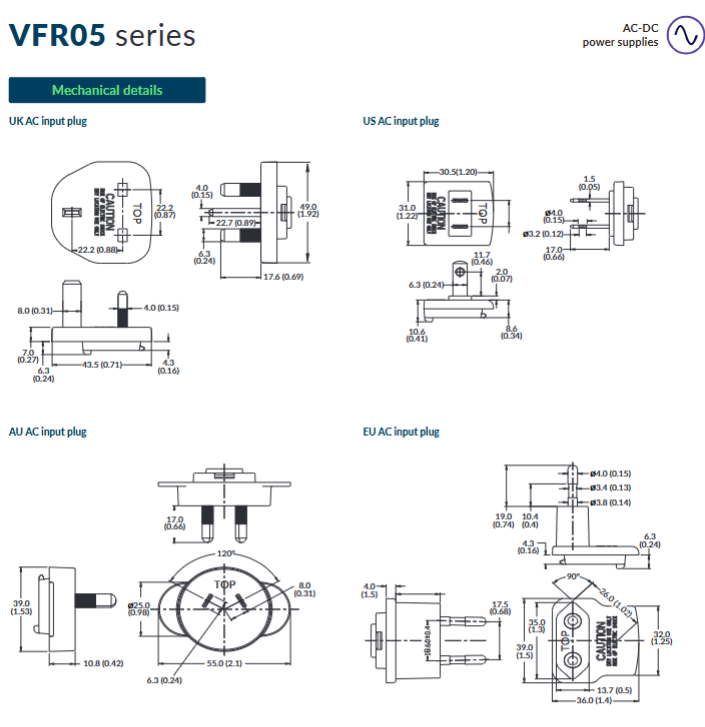

Please refer to Figure 5-3 to confirm the physical dimensions and reserve gaps for installation, disassembly, and maintenance

A gasket needs to be added between the installation surface and the governor base to ensure that the installation is square and the transmission connection is aligned

The transmission gear needs to have no jamming or excessive backlash to avoid affecting the stability of speed regulation

(2) Oil specifications and requirements

Specific project parameters

Oil type: Hydraulic lubricating oil (compatible with nitrile, polyacrylic acid, fluorocarbon sealing materials)

Viscosity range: 50-3000 SUS at operating temperature, ideal 100-300 SUS

Applicable standard API “5” group or “C” group (SA-SF, CA-CD), MIL-L-2104A, etc

Temperature requirement: Continuous working oil temperature of 60-93 ℃, ambient temperature of -29-93 ℃

The oil capacity is 29 ft lb (39 J) and the rotary servo governor is 1.6 US quarts (1.5 liters)

The replacement requirement is to replace the oil immediately when it deteriorates/becomes contaminated, and the ideal working condition can be extended to more than 6 months

(3) Key adjustment operations

Connecting rod adjustment: Ensure that the fuel/steam valve is just closed when the power piston of the governor reaches the end of its stroke in the “closing” direction; Fully open fuel control before maximum travel

Start speed setting: set the direct acting governor to the minimum speed, and the reverse acting governor to the maximum speed (set to the minimum when the air pressure signal is unknown)

Compensation needle valve adjustment: Open the needle valve at idle until the engine fluctuates, then gradually close it until the fluctuation is eliminated, and keep it open for 1/16-2 turns

High and low speed adjustment: By setting the speed control nut, limit screw, etc., ensure that the minimum control air pressure corresponds to the minimum speed, and the maximum control air pressure corresponds to the maximum speed (direct speed control)

Working principle

(1) Core functions

Implement isochronous control: Within the capacity range of the prime mover, maintain a stable speed regardless of load changes

Control logic: By adjusting the fuel or steam supply, respond to changes in engine speed

(2) Key components and mechanisms

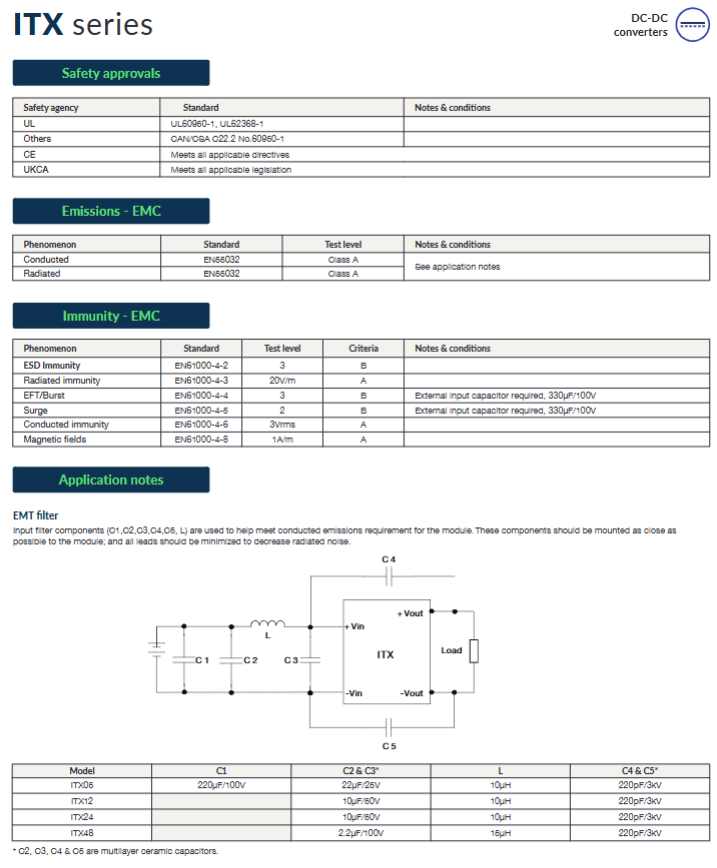

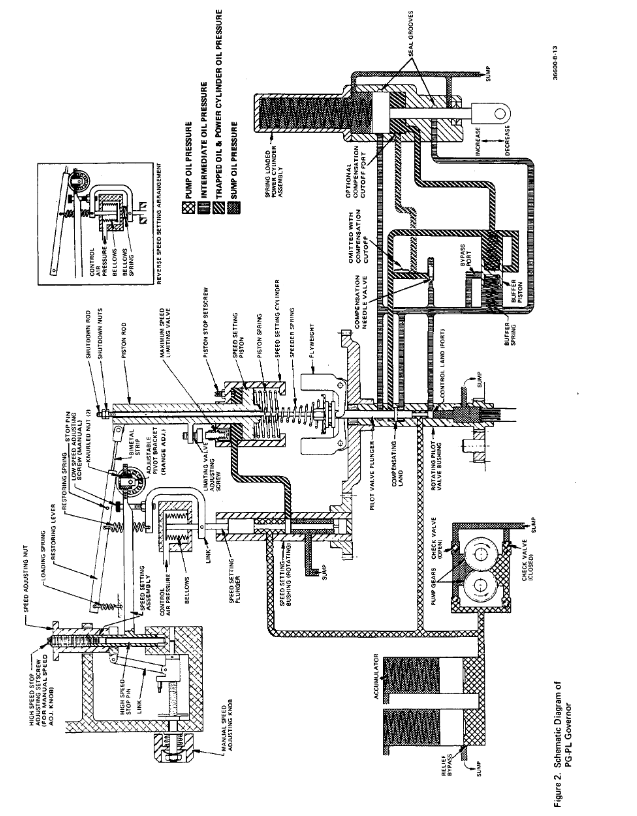

Core components: oil pump, pressure storage area, relief valve, flyweight head directional valve assembly, power cylinder, compensation system, pneumatic speed control mechanism

Speed regulation mechanism

Direct speed regulation: control the increase of air pressure → increase of speed (minimum 3 psi, maximum 100 psi)

Reverse speed regulation: control the increase of air pressure → decrease of speed

Manual speed regulation: When there is no air pressure signal, adjust it within the normal speed range through the knob

Response to special working conditions

Temperature compensation: The old model uses bimetallic strips, while the new model is integrated into the speed regulating spring

Signal loss: Direct speed regulator reduces to minimum speed, reverse speed increases to maximum speed

Maintenance and upkeep

(1) Troubleshooting steps

Confirm if the load exceeds the capacity of the prime mover

Check the working status of the prime mover (engine cylinder ignition, turbine steam valve, etc.)

Check if the connecting rod is stuck or has empty travel

Check for changes in steam/fuel pressure

Verify the compensation needle valve setting and the output pressure of the pneumatic transmitter

Detect the working oil pressure of the governor (standard 100 psi)

(2) Disassembly and assembly

Dismantling sequence: Operate according to the index numbers in Figure 5-1 and 5-2, discard old gaskets, O-rings, etc

Cleaning requirements: Use compatible solvents for ultrasonic cleaning, blow dry with compressed air, and avoid scratching with metal brushes

Assembly specification: Operate in a dust-free environment, apply clean lubricating oil to moving parts, and tighten bolts to the specified torque (such as 45 lb ft for power cylinder bolts)

(3) Parts maintenance

Key inspection points: bearings (replace if there is roughness), flyweight (replace if worn), speed regulating springs (replace if corroded/damaged)

Replacement requirement: Information such as the serial number, part number, manual number, etc. of the speed controller must be provided

Auxiliary functions and membrane speed regulation

(1) Optional auxiliary device

Function and requirements of auxiliary devices

When the oil temperature of the governor oil cooler exceeds 93 ℃ or the speed exceeds 1200 rpm (engine)/1100 rpm (turbine), it is necessary to equip it

The shutdown device includes pneumatic/hydraulic/hydraulic type and electromagnetic type, and cannot be used as overspeed protection (independent overspeed device is required)

Pre loaded buffer spring reduces fuel linkage fluctuations caused by misfire or pump instability

Boost servo motor assists in quick engine start, immediately pushing the connecting rod to the fuel on position

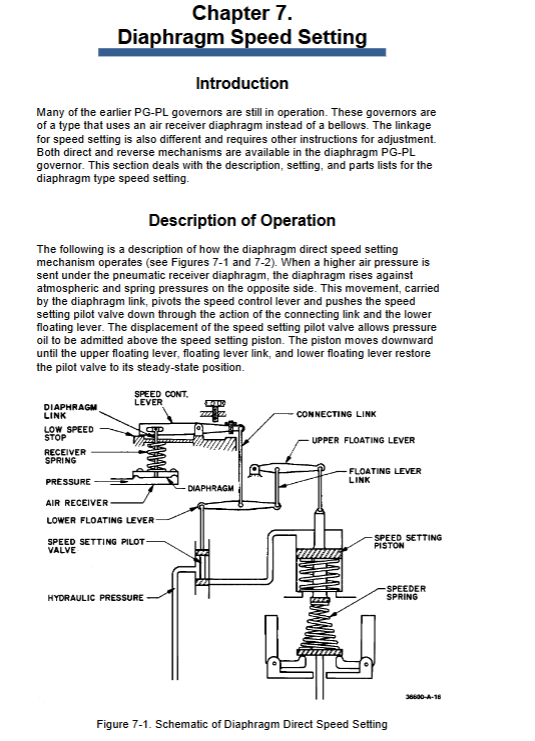

(2) Diaphragm speed regulation setting

Applicable scenario: Early PG-PL speed controller (using air receiver diaphragm instead of bellows)

Adjustment logic: Set the correspondence between air pressure and speed through sliding blocks, idle screws, and base speed adjustment nuts. The direct and reverse types require adjustment of the connecting rod arrangement