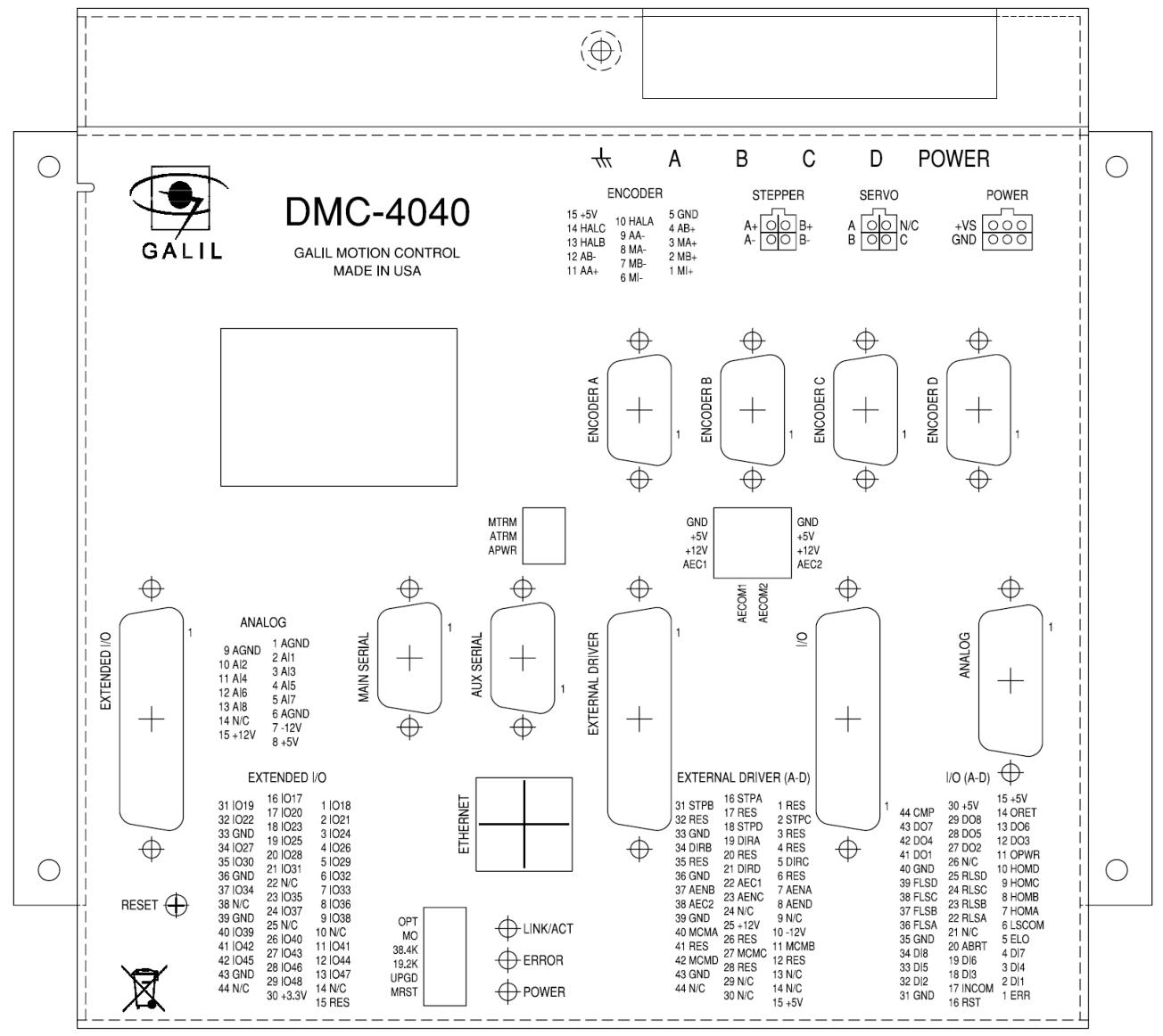

Galil DMC-40×0 series motion controller

Overview

Controller Introduction

The DMC-40×0 series is a Galil high-performance independent controller that supports up to 8-axis control, with high-speed communication, non-volatile program memory, faster encoder speed, and improved EMI reduction wiring.

Provides two communication channels, RS-232 (2-channel, maximum 115K baud rate) and 10BaseT Ethernet, supporting high-speed servo control with up to 22 million encoder counts per second and stepper motor control with 6 million steps per second, with a sampling rate as low as 31.25 µ sec/axis.

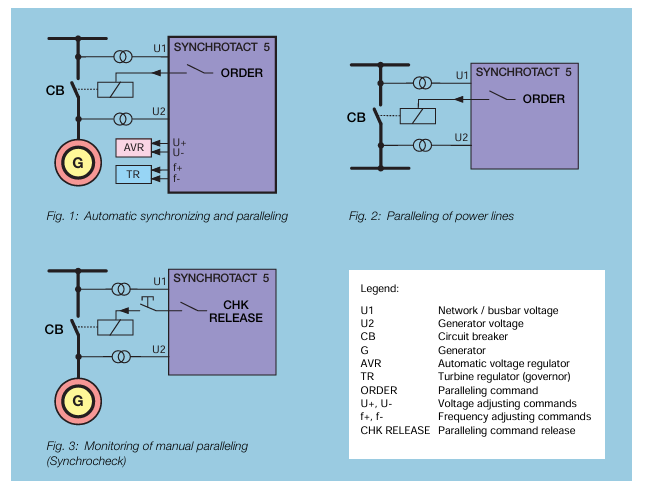

Flash EEPROM provides non-volatile memory for storing application programs, parameters, arrays, and firmware, which can be upgraded on-site.

Supported motor types

Standard servo motor with ± 10V command signal

Brushless servo motor with sinusoidal commutation

Stepper motor with step and direction signals

Other actuators (such as hydraulic devices, please contact Galil for more information)

Overview of External Amplifier

Current mode amplifier: accepts analog command signals within the ± 10V range, and the amplifier gain should be set to+10V command to generate the maximum required current.

Speed mode amplifier: The 10V command signal should cause the motor to operate at the maximum required speed.

Stepper motor amplifier: accepts step and direction signals.

Overview of Galil amplifiers and drivers

A1- AMP-430×0 (- D3040, – D3020): Multi axis brushed/brushless amplifier, capable of processing 500 watts of continuous power per axis, accepting 18-80VDC DC power supply voltage.

A2-AMP-43140 (- D3140): Contains four linear drivers for operating small brushed servo motors, requiring ± 12-30 DC voltage input, with an output power of 20W per amplifier and a total power of 60W.

A3-SDM-44040 (- D4040): Stepper driver module capable of driving up to four bipolar two-phase stepper motors, with selectable currents of 0.5, 0.75, 1.0, and 1.4 amperes per phase, and selectable step resolutions of full step, half step, 1/4, and 1/16.

A4- SDM-44140 (- D4140): Microstep module, driving four bipolar two-phase stepper motors with 1/64 microstep resolution (SDM-44140 drives two), with selectable current of 0.5, 1.0, 2.0, and 3.0 amperes per axis.

Beginner’s Guide

Layout and Size

Introduced the layout and size information of DMC-4040 and DMC-4080.

power connection

The power connector information for controllers without Galil amplifiers or when ordering ISCNTL power options, as well as the power connector information for controllers with Galil integrated amplifiers.

Required components

Including DMC-40×0 motion controller, motor amplifier (integrated when using Galil amplifier and driver), power supply for amplifier and controller, brushed or brushless servo motor or stepper motor with optical encoder, cable connected to DMC-40×0 integrated ICM, PC (RS232 or Ethernet for DMC-40×0), GalilTools or GalilTools Lite software package.

Installation steps

Determine the overall motor configuration, install jumpers on DMC-40×0, install communication software, connect 20-80VDC power supply to the controller, establish communication with Galil software, determine the axis for sine commutation, connect to amplifiers and encoders, connect standard servo motors/sine commutation motors/stepper motors, and adjust the servo system.

Hardware connection

Optical isolation input

Including limit switch input, origin switch input, abort input, ELO (electronic lock) input, reset input, and unconfirmed digital input, their functions, wiring, and electrical specifications are introduced.

TTL input

The auxiliary encoder input can be used for general purposes, with one auxiliary encoder per axis, containing two inputs, and can accept TTL level signals, etc.

High power optical isolation output

Introduced its electrical specifications and wiring methods, the outputs 9-16 of the 5-8 axis controller are located on the I/O (E-H) D-Sub connector.

analog input

There are eight analog inputs configured in the range of -10V to 10V, and different ranges and modes can be set through the AQ command. The electrical specifications are introduced.

TTL output

Including output comparison, error output, etc.

Expansion I/O of DMC-40×0 Controller

Provides 32 extended TTL I/O points that can be configured as inputs or outputs in 8-bit increments, and introduces their electrical specifications.

Amplifier interface

Introduced its electrical specifications and overview, as well as the ICM-42000 and ICM-42100 amplifier enable circuits, and the ICM-42200 amplifier enable circuit.

Software tools and communication

RS232 and RS422 ports

Introduced RS-232 and RS-422 configurations, including pin descriptions, configuration methods, baud rate selection, and handshake.

Ethernet configuration

Supports two industry standard protocols, TCP/IP and UDP/IP, and introduces addressing methods including MAC address, IP address, and UDP or TCP port number.

communication protocol

Introduced communication methods with multiple devices and multicast functionality.

Third party software usage

Supports tools such as DHCP, ARP, BOOT-P, and Ping for establishing Ethernet connections, and can communicate with hosts through any application that can send TCP/IP or UDP/IP packets, such as Telnet.

Modbus

An RS-485 protocol is introduced, including its function code, communication level, and examples.

data record

The status information block can be provided through QR commands, which introduces the mapping of data records and the interpretation of bit fields.

GalilTools (Windows and Linux)

It is a software toolset provided by Galil for the current Galil controller, which includes multiple tools and can run on both Windows and Linux platforms.

Create custom software interface

Provide programming tools such as GalilTools communication library, ActiveX Toolkit,. NET API, and DMCWin to facilitate users in developing their own custom software interfaces.

Command Fundamentals

introduce

Provide over 100 commands for specifying motion and machine parameters, which can be sent via ASCII or binary.

ASCII command syntax

The instruction consists of two uppercase letters followed by applicable arguments, terminated with a semicolon or carriage return, and introduces the syntax for specifying axis data and requesting actions.

Binary Command Syntax (Advanced)

The binary communication mode is about 20% faster than ASCII commands. The binary format can only send commands from a PC and cannot be embedded in applications. This article introduces the binary command format and tables.

Controller’s response to data

Return ‘:’ for valid commands and ‘?’ for invalid commands, error codes can be requested through the TC1 command.

Inquire about the controller

There is a set of commands that directly query the controller and return the required data, introducing the query commands and operands.

Sports programming

overview

Provides multiple motion modes, such as independent positioning and jogging, coordinated motion, electronic cam motion, and electronic gear transmission, and introduces application examples applicable to different modes.

Independent axis positioning

Each axis moves independently and follows its own contour. Relevant commands and operands, as well as examples, are introduced.

Independent Jogging

The ability to change speed, direction, and acceleration during motion is introduced, along with relevant commands and operands, as well as examples.

Position Tracking

This article introduces the characteristics and examples of a target that allows absolute position movement to be changed during motion.

Linear interpolation mode

Multi axis motion coordination, maintaining specified vector velocity, acceleration, and deceleration along a specified path, introducing relevant commands and operands, as well as examples.

Vector mode: Linear and circular interpolation motion

Allow the specification of long 2-D paths consisting of linear and circular arc segments, introduce relevant commands and operands, and provide examples.

Electronic gear transmission

Up to 8 axes can be connected to certain main axis electronic gears, and relevant commands and examples are introduced, including bevel gear transmission.

Electronic cam

A motion control mode that supports periodic synchronization of multiple motion axes, introducing relevant commands and examples.

PVT mode

Allowing the definition of arbitrary motion contours for all 8 axes through position, velocity, and time, relevant commands and examples are introduced.

Multi axis coordinated motion

Many applications require multiple axes to move in a coordinated manner, while also requiring smooth motion. An example was introduced.

contour mode

Allowing the specification of curves at any position for 1 to 8 axes, introduces relevant commands and examples, including recording and playback functions.

Stepper motor operation

Introduced the relevant commands for operating stepper motors, smoothing functions, methods for using encoders, and the Stepper Position Maintenance Mode (SPM).

Double loop (auxiliary encoder)

Except for the shaft configured for stepper motor operation and the shaft used for circular comparison, each shaft provides a second encoder interface, and its purpose and related commands are introduced.

**Backlash compensation**

Two methods of using auxiliary encoders for backlight compensation were introduced: continuous dual loop and sampling dual loop.

Motion Smoothing

Smooth motion and reduced mechanical vibration of the system can be achieved through IT and KS commands.

zeroing

The Find Edge (FE) and Home (HM) commands can be used to zero the motor to the mechanical reference point, and the steps and related commands for zeroing are introduced.

High speed position capture (latch function)

The position of the main encoder or auxiliary encoder can be captured within 25 microseconds of external low input signals (or index pulses), and its usage steps and examples are introduced.

Quick update rate mode

It can run at a much faster servo update rate than the default per millisecond, and introduces the update rates and related limitations of different models of controllers.

Application Programming

overview

Provide a powerful programming language that allows users to customize controllers for specific applications. The program can be downloaded to DMC-40×0 memory, freeing up the host for other tasks.

Using DMC-40×0 editor to input program

The GalilTools package or the line editor provided by DMC-40×0 can be used to input and modify programs, and the editing mode commands are introduced.

Program Format

Composed of DMC instructions, action instructions are combined with program flow instructions to form a complete program, introducing the use of tags and special tags.

Comment

You can use the NO command or apostrophe (‘) to add comments to the program.

Executing Programs – Multitasking

Up to 8 independent programs (threads) can run simultaneously, and instructions for starting and stopping threads are introduced.

debugger

Provide commands and operands that help debug applications, such as trace commands, error code commands, stop code commands, etc.

Program flow command

Including event triggers and conditional jumps, the program flow can be changed based on the occurrence of events.

Mathematics and Function Expressions

Provides a variety of mathematical operators and functions that can be used for data manipulation.

variable

Provides 510 variables that can be used to store mutable parameters, and introduces the definition and assignment of programmable variables.

array

Used for storing and collecting numerical data, this article introduces the definition, assignment, upload and download of arrays, as well as automatic data capture functions.

Data input (numerical and string)

The IN command can be used to prompt the user to enter numerical or string data, introducing the operator data input mode and the use of communication interruption.

Data output (numerical and string)

MG commands can be used to output numerical and string data, introducing message sending, port specification, and formatting.

Hardware I/O

Introduced the usage methods of digital output, digital input, auxiliary encoder input, input interrupt function, analog input, and extended I/O.

Example application

Examples include line cutters, X-Y worktable controllers, speed control through joysticks, position control through joysticks, and backlight compensation through sampling dual loops.

Hardware and software protection

overview

Providing multiple hardware and software functions to check for error conditions and disable motors in case of errors helps protect various system components from damage.

hardware protection

Including output protection lines (such as amplifier enable, error output) and input protection lines (such as universal stop, selective stop, ELO, forward limit switch, reverse limit switch).

software protection

Provides programmable error limits that can set limit values for position errors, introduces programmable position limits, Off On Error functionality, automatic error programs, and limit switch programs.

Troubleshooting

overview

Potential issues are classified into three categories: installation, stability and compensation, and operation. Various symptoms, diagnoses, causes, and remedial measures are introduced.

Operational theory

overview

Discussing the operation of a motion control system, a typical motion control system consists of multiple elements, and the operation can be divided into three levels: closed-loop, motion contour, and motion programming.

Closed loop system operation

Qualitatively and quantitatively explained the operation of the servo system, including the principle of closed-loop control, the causes of instability, and the role of PID filters.

system modeling

Established mathematical models for various elements of the servo system, such as motor amplifier, encoder DAC、 Digital filters and ZOH.

system analysis

Starting from the block diagram model of system elements, analyze to determine the stability of the system.

System design and compensation

Aiming to close the loop with cross frequency and phase margin, the analysis and design methods are introduced.

appendix

Electrical specifications

Electrical specifications including servo control, stepper control, input/output, and power requirements.

Performance specifications

Including performance parameters such as minimum servo loop update time, position accuracy, and speed accuracy.

Quick update rate mode

Introduced the update rate and disabled features in fast mode.

Ordering options for DMC-40×0

Introduced controller board options, CMB communication board options, ICM interconnect board options, and AMP internal amplifier options.

DMC-40×0 power connector

Introduced the Molex connector models and cable connections used.

Integration Components

Detailed descriptions, electrical specifications, mating connectors, and operation information of integrated components such as A1 to A8 were provided.