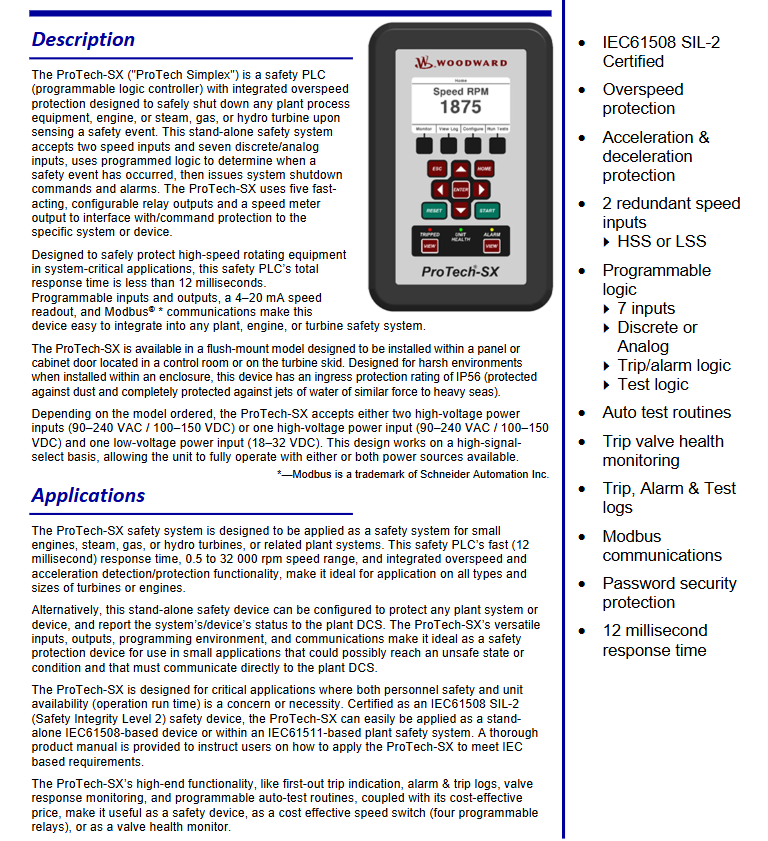

Woodward ProTech SX Security System

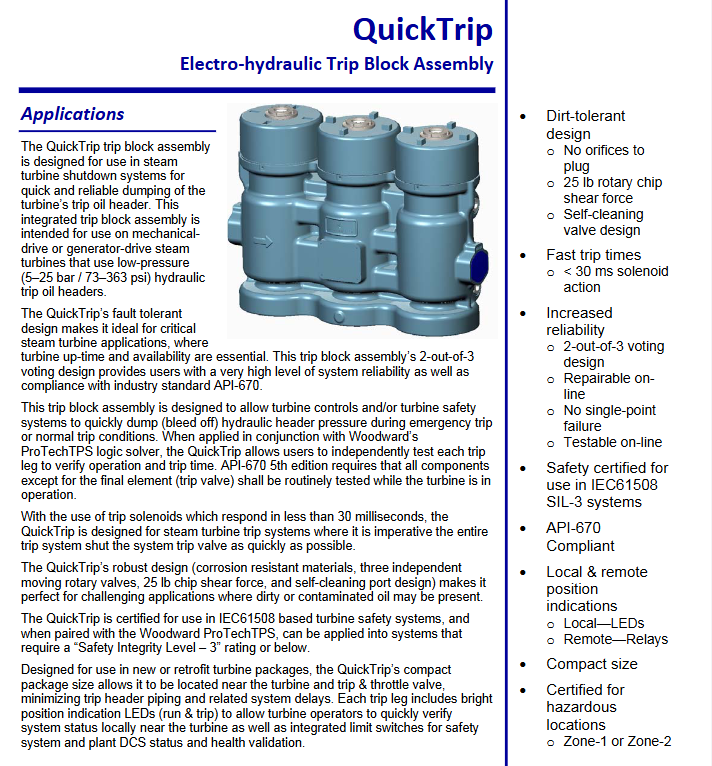

The Woodward ProTech SX safety system is an IEC61508 SIL-2 certified safety PLC, designed for the safety protection of small engines, steam/gas/water turbines, and other equipment. It has a 12 millisecond fast response, 0.5-32000 RPM speed range, supports 2 redundant speed inputs and 10 analog/discrete inputs, and is equipped with 5 solid-state outputs and 4-20mA speed analog outputs. It integrates overspeed/acceleration/deceleration protection, trip valve health monitoring, log recording (50 trips/alarms+20 overspeed events), Modbus communication, and other functions, with a protection level of IP56. It can be programmed and configured through software tools and is suitable for personnel and equipment safety protection in critical scenarios.

Core parameters and hardware configuration

(1) Key performance parameters

Specific indicators for parameter categories

Response time of 12 milliseconds (from security event detection to shutdown command output)

Speed range 0.5-32000 RPM

Protection level IP56 (dustproof, anti strong water spray)

Working temperature -20 ° C to+60 ° C

The storage temperature is consistent with the working temperature

The clock function has a built-in real-time clock and supports external DCS time synchronization signal input

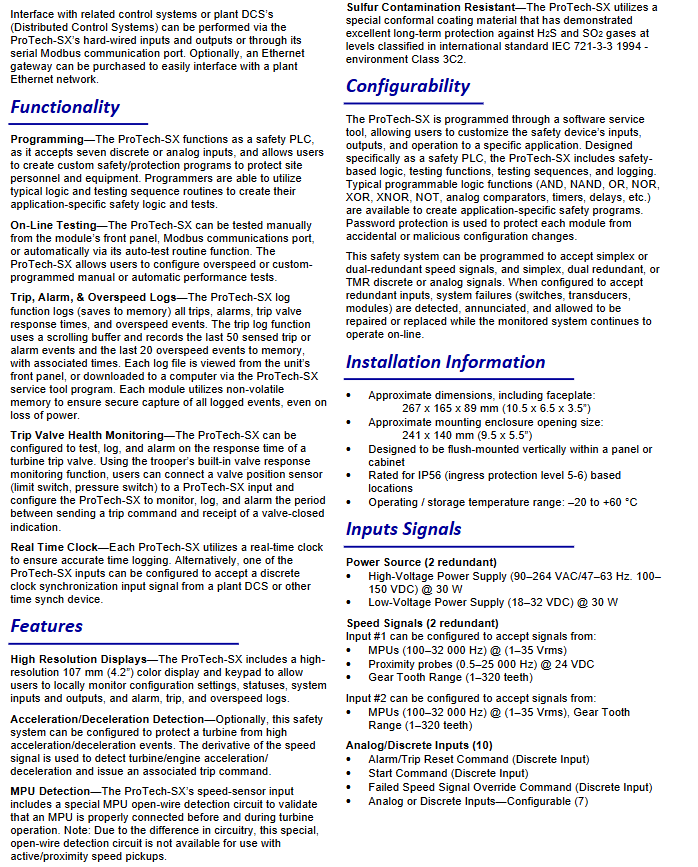

(2) Input configuration

Enter type specification details

There are two power input modes to choose from:

1. Dual redundant high voltage input (90-240 VAC/47-63Hz or 100-150 VDC, 30W)

2. Single high voltage+single low voltage input (high voltage as above, low voltage 18-32 VDC, 30W)

Speed input (2-channel redundant) Input 1: Supports MPU (100-32000 Hz, 1-35 Vrms), proximity probe (0.5-25000 Hz, 24 VDC), gear teeth 1-320

Input 2: Only supports MPU (parameters are the same as input 1), with gear teeth ranging from 1-320

Signal input (10 channels) includes 3 fixed discrete inputs (alarm/trip reset, start command, speed signal failure override)+7 configurable inputs (analog/discrete optional)

Special detection MPU open circuit detection (only applicable to MPU sensors, not applicable to active/proximity probes)

(3) Output configuration

Output type specification details

Discrete output (5 solid-state) and 2 shutdown relay outputs: 1A@24 VDC

3-channel programmable relay output: 1A@24 VDC (supporting functions such as alarm, trip, speed switch, etc.)

Analog output (1 channel) 4-20 mA, dedicated for tachometer reading output

Auxiliary power supply 24 VDC, 0.5 A, used for intermediate relay circuit

Core functions and features

protection function

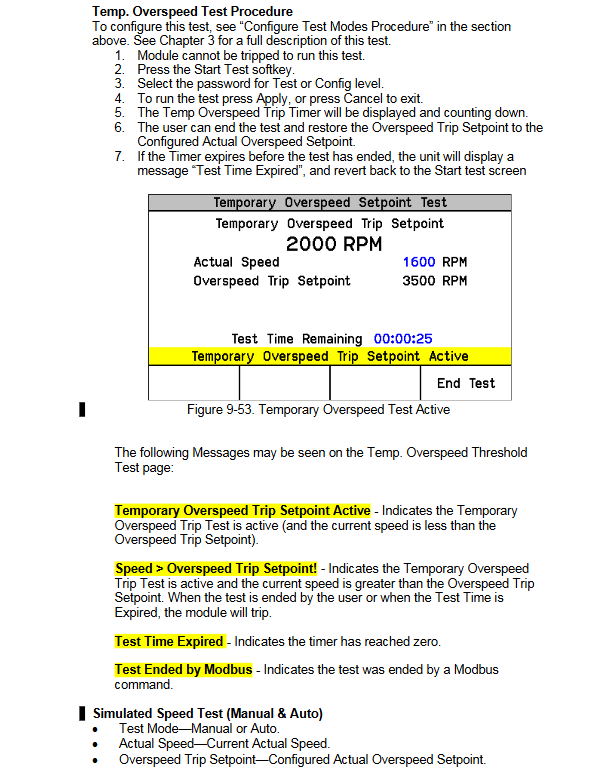

Overspeed protection: Accurate monitoring of speed, triggering shutdown command when exceeding the set value

Acceleration and deceleration protection: optional configuration, detecting abnormal acceleration and deceleration through the derivative of the speed signal, triggering protection

Anti pollution design: using a special conformal coating that can withstand H ₂ S and SO ₂ gases of IEC 721-3-3 1994 Class 3C2 level

MPU open circuit detection: Verify the connection status of MPU sensors before startup and during operation to ensure signal reliability

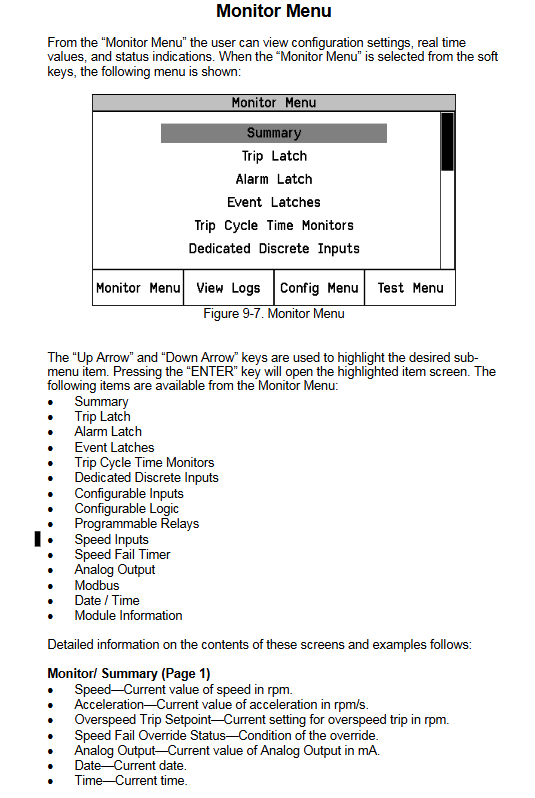

Monitoring and diagnostic functions

Trip valve health monitoring: connect valve position/pressure sensors, monitor the response time from “trip command issued to valve closed”, support logging and alarm recording

Status feedback: Real time feedback on equipment operation status, input/output signal status, and integration with factory DCS

Programming and Configuration

Programming ability: Supports standard logic functions (AND, NAND, OR, NOR, XOR, XNOR, NOT), analog comparator, timer, delay, etc., customizable security logic

Configuration method: Programming through dedicated software service tools, supporting simplex/dual redundancy/TMR signal configuration

Security protection: Password protection function to prevent accidental operation or malicious modification of configurations

Logs and Communication

Log recording: non-volatile memory storage, no data loss during power outage

Trip/Alarm Log: Record the last 50 events (including timestamps)

Overspeed log: Record the last 20 overspeed events (including timestamps)

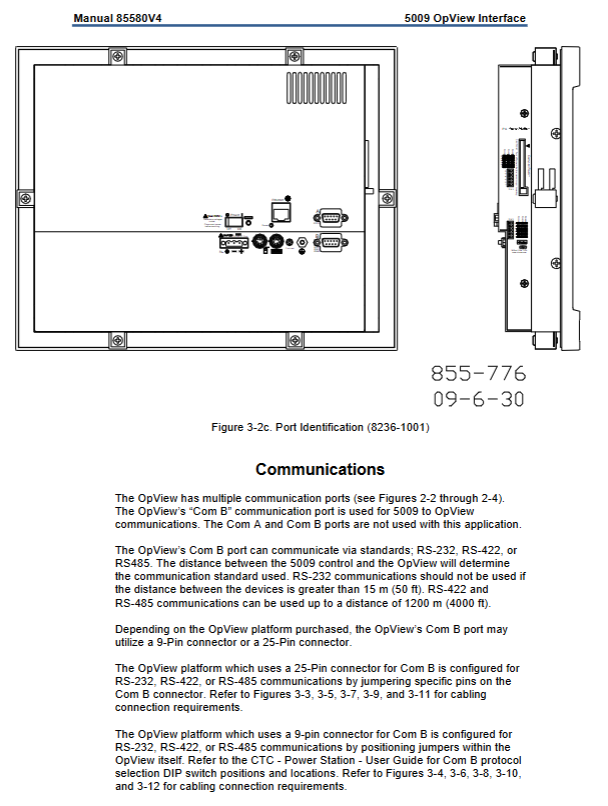

Communication interface: 1 serial communication port (supporting RS-232/RS-422/RS-485), Modbus protocol; Optional Ethernet gateway for factory Ethernet connection

Installation and physical specifications

Specification category specific parameters

Overall dimensions (including panel) 267 x 165 x 89 mm (10.5 x 6.5 x 3.5 inches)

Installation opening size 241 x 140 mm (9.5 x 5.5 inches)

Installation method: Embedded vertical installation (control panel or cabinet door)

Compliance certification

Regional/Standard Certification Details

North American CSA certification (Class I, Division 2, Groups A-D, T4, 60 ° C environment)

Europe EMC Directive 2014/30/EU、ATEX Directive 2014/34/EU(II 3 G, Ex ec nC IIC T4 Gc)、LVD Directive 2014/35/EU、RoHS 2011/65/EU

UK Electromagnetic Compatibility Regulations 2016, Explosion proof Equipment Regulations 2016, Electrical Equipment Safety Regulations 2016

International IEC61508 SIL-2 (T Ü V certification) API670、API612、IEC60068-2-60、 Australian RCM certification (applicable only to EMC)