Core positioning and value of the product

ABB Ability ™ Symphony ® The Plus MR series (also known as Melody Rack) is a modular, high availability, and easy to configure efficient control system, mainly aimed at industrial fields such as power generation and water treatment. Its core goal is to help users improve production control efficiency, maximize process availability, reduce maintenance costs, and support rapid response to market demand changes, adapting to automation tasks in factories of different sizes through flexible architecture and powerful functions.

Traditional production facilities require the maintenance of multiple independent controller subsystems, while the MR series integrates multifunctional capabilities through an extensible controller platform that combines openness and high availability, avoiding compatibility issues with multiple systems, reducing overall operational complexity, and bringing higher returns to enterprise assets.

Core functions and technical features

1. Flexible hardware architecture and I/O system

(1) Modular assembly and installation method

Deployment form: Supports distributed DIN rail installation, can be combined with local I/O or remote I/O (such as ABB S800, S900 series and other PROFIBUS remote I/O), suitable for centralized or decentralized system layouts;

Installation compatibility: Provides three installation methods: cabinet installation, DIN rail installation, and 19 inch rack installation, which can be combined and used in the same project to facilitate the upgrading and renovation of existing facilities;

Space optimization: The high packaging density of local I/O modules can minimize installation space and reduce cabinet occupancy costs.

(2) Comprehensive I/O types and functions

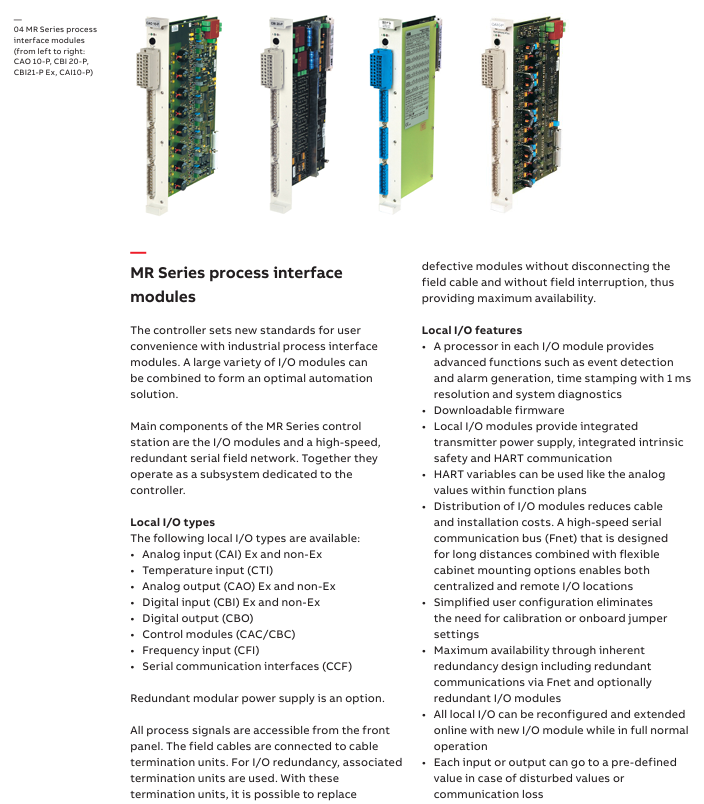

The MR series provides a wide range of local I/O modules, covering common signal requirements in industrial scenarios, and supporting intrinsic safety (Ex i) design and HART communication. The specific types and features are as follows:

Specific classification of I/O module types and core functions

Analog Input (CAI) Ex version/non Ex version integrated transmitter power supply, 1ms resolution timestamp, signal monitoring and filtering, supports equal use of HART variables and analog signals

Temperature Input (CTI) – Accurately collects temperature signals and adapts to different industrial temperature measurement scenarios

Analog output (CAO) Ex version/non Ex version provides continuous control signals and supports preset value output under fault conditions

Digital input (CBI) Ex/non Ex version event detection and alarm generation, 1ms timestamp, compatible with switch signal acquisition

Digital Output (CBO) – controls external actuators (such as solenoid valves) and supports redundant configurations to enhance availability

Control module (CAC/CBC) CAC 10-P (closed-loop output), CBC 11-P (drive control) CAC is used for continuous controllers, PI step controllers, etc; CBC is used for switch actuators, motor drives, etc., and can operate independently of the controller

Frequency Input (CFI) – collects frequency signals, adapts to monitoring parameters such as speed and flow rate

Serial Communication Interface (CCF) – expands external communication such as Modbus and PROFIBUS, supporting third-party device access

(3) I/O redundancy and maintenance convenience

Redundant design: Supports I/O module redundancy, communication bus (Fnet, high-speed serial bus) redundancy, and power module can also choose redundant configuration to ensure no single point of failure;

Online maintenance: By using dedicated wiring terminal units, it is possible to replace faulty I/O modules without disconnecting on-site cables and without interrupting the production process;

Online expansion: I/O modules can be reconfigured or added during normal system operation without downtime, ensuring process continuity.

High performance controllers and control capabilities

(1) Core parameters and functions of the controller

The MR series controller (represented by PM877) has powerful computing and control capabilities, suitable for complex industrial scenarios, and key features include:

I/O processing capability: A single controller can handle local I/O (2000 analog/digital points)+PROFIBUS DP remote I/O (6000 analog/digital points), totaling 8000 I/O points;

Control function coverage: supports open-loop/closed-loop control, sequential control, batch control, and advanced control (such as formula management based on S88 standard and fault handling based on NAMUR standard), meeting complex control strategies in fields such as power generation and water treatment;

Performance: Equipped with a real-time multitasking operating system, supporting 16 different cycle times, with a time synchronization accuracy of 0.5ms between controllers and a sequence of events (SOE) timestamp resolution of 1ms, ensuring real-time performance and data accuracy;

Diagnosis and safety: Regularly check the integrity of hardware and firmware, and automatically report abnormal states to HMI or alarm system; Compliant with network security standards (DSAC), the battery free design reduces maintenance costs, and the performance is improved compared to the previous generation product (CMC 50/60), with power consumption reduced by 50% compared to PM875/876.

(2) Redundancy guarantee and seamless switching

The controller adopts a “hot standby” redundancy design, which does not require additional configuration or wiring:

The main controller and backup controller operate synchronously with the same control strategy and process data;

If the main controller fails, the backup controller immediately takes over control, achieving “disturbance free switching” and ensuring system availability (high average time between failures).

Standardized communication and network architecture

(1) Multi level communication network

The MR series adopts a layered and functionally segmented network architecture to ensure real-time control and operational flexibility. The specific levels are as follows:

Technical characteristics of core functions at the network level

Control the network to achieve real-time signal interaction between controllers and between controllers and I/O modules, closed-loop control and protection signal transmission redundant high-speed serial network, no routing configuration required, supports remote communication, and is not affected by operational layer message traffic

Operate network connection engineering workstations (S+Engineering), operation workstations (S+Operations), and system servers to transmit visual data, configuration information, and maintenance instructions, supporting simultaneous access by multiple users

Fieldbus interface docking with third-party devices and intelligent electronic devices (IEDs) supports PROFIBUS DP (DPV0/DPV1/DPV2), Modbus RTU/TCP, IEC 61850 (electrical subsystem integration)

(2) Key communication interface capability

PROFIBUS DP: A single controller supports 2 PROFIBUS lines, each line can be redundant, the transmission rate is adjustable from 9.6kbit/s to 12Mbit/s, supports PROFIBUS-DP/PA converters, and is compatible with Ex area devices;

Modbus: The local interface card provides Modbus RTU, and the controller has built-in Modbus TCP. A single controller supports 128 Modbus TCP servers and 16 Modbus TCP slaves, making it easy to interface with third-party instruments PLC;

IEC 61850: Intelligent Electronic Devices (IEDs) that directly integrate electrical subsystems without the need for additional gateways, simplifying the integrated design of electrical and control systems in the field of power generation.

Efficient engineering tools and software support

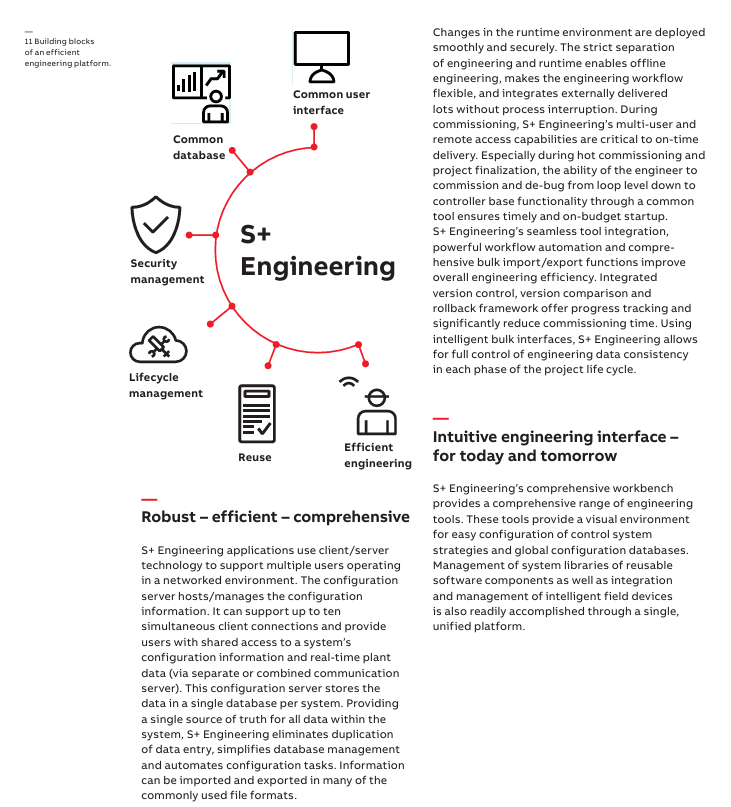

(1) S+Engineering for Melody Engineering Platform

This platform is the core configuration tool of the MR series, which achieves efficient project management through a client server architecture. Its core advantages include:

Single source data management: System configuration information is stored in a single database, eliminating duplicate data entry, ensuring data consistency, and supporting import/export of common file formats (such as Excel);

Multi user collaboration: The configuration server supports simultaneous connection of 10 clients, and engineers can remotely debug (from loop level to controller basic functions), which is suitable for efficient progress in hot debugging and project closure stages;

Version and Lifecycle Management: Integrated version control, version comparison, and rollback functions, supporting offline engineering design to avoid the impact of online modifications on production; Support replacing old modules (such as CMC 50/60/70, PM875/876) with new modules (such as PM877) without changing the existing topology and control logic;

Function Block Library: Provides a powerful function block library that has been verified on site, covering simple controls (such as MAX/MIN, 2 out of 3 logic), complex controls (such as polygon curves, batch formulas), supports user-defined function block libraries, and is programmed based on IEC 61131-3 standard Sequential Function Diagram (SFC).

(2) On site equipment integration

Through standardized FDT/DTM (Field Device Tool/Device Type Manager) interfaces, on-site devices can be “plug and play”, and configuration and diagnostic information can be transmitted to the system layer through the control network, supporting asset optimization and device management applications.

System compatibility and lifecycle advantages

1. Backward compatibility and smooth upgrade

The MR series follows ABB’s “evolution without exclusion” philosophy to ensure compatibility between old and new systems

Hardware compatibility: New I/O modules and controllers (such as PM877) are compatible with previous generation modules (such as CMC series) in terms of installation size and functional interfaces. Existing I/O cards can be retained for use (supporting 375kBaud and 2Mbit cards);

Software support: S+Engineering for Melody provides a tool for replacing old modules, without the need to rewrite control logic. Simply update the firmware to extend new features (such as adding IEC 61850 interfaces);

Investment protection: Users can reuse the factory specific control strategies and operational processes accumulated by decks to avoid “starting over” during upgrades and reduce capital and labor costs.

2. Industry Applications and Case Scale

The MR series is widely used in the fields of power generation and water treatment. As of document release (2018):

We have provided control solutions for over 60000 MW of new power generation projects worldwide;

The installed capacity covers multiple types of units, such as NEU (50 units), NAS (40 units), CEU (860 units), MED (120 units), etc., with a total of over 1200 devices in operation, verifying the maturity and reliability of the technology.

Leave a comment

Your email address will not be published. Required fields are marked *