Overview

This document is the GA800 Industrial AC Inverter Selection Guide (document number SL. GA800.01) released by Yaskawa USA in 2021. It introduces the multi voltage levels (240V/480V/600V), dual duty ratings (Normal Duty/Heavy Duty), and corresponding model parameters of GA800 inverters, covering core data for inverter selection (such as output current, power range), supporting components (reactors, filters, braking units, etc.), configuration package solutions (Type 1/12/3R enclosure), technical parameters (overload capacity, protection level, etc.), as well as training services and sales terms, providing comprehensive selection support for Yaskawa salespeople, distributors, and partners.

GA800 inverter core selection parameters

1. Voltage and power range (key numbers)

Voltage level, phase number, power range (HP), core model example, applicable scenarios

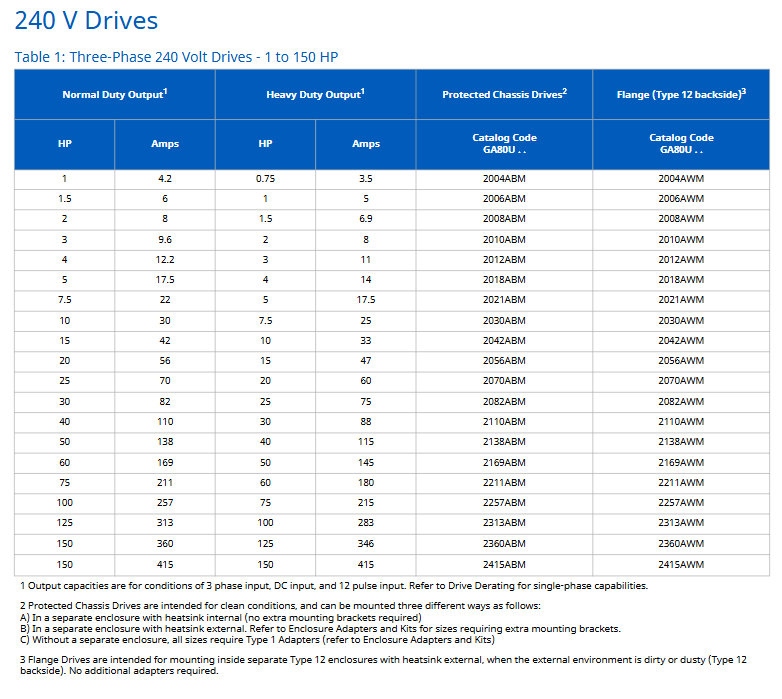

240V Class 3-phase 1-150 2004ABM (1HP ND), 2360AWM (150HP ND) low-power motors, such as small pumps/fans

480V Class 3-phase 1-1000 4002ABM (1HP ND), 4H12AAM (1000HP ND) medium and high-power equipment, such as compressors/machine tools

600V Class 3-phase 125-500 5125ABM (125HP ND), 5472AWM (500HP ND) high-voltage industrial scenarios, such as large transmission systems

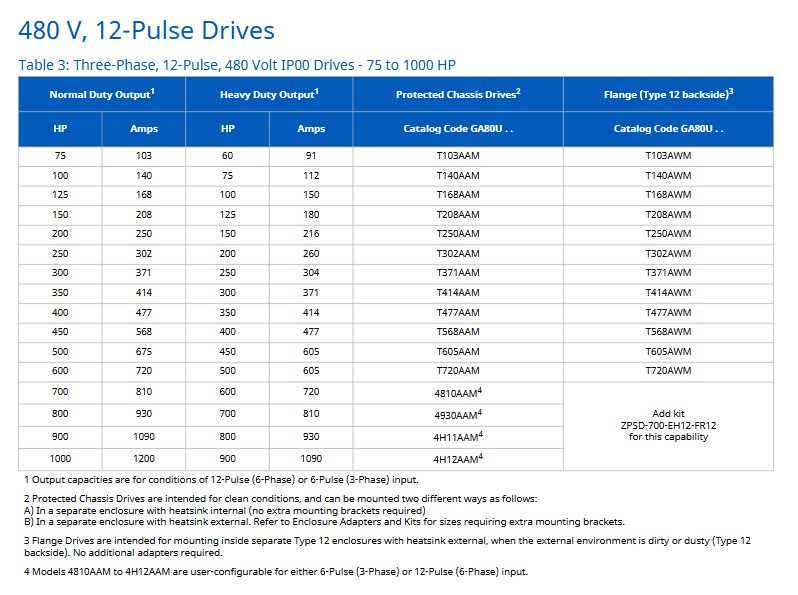

Scenarios where harmonic reduction is required for 480V 12 Pulse 3-phase 75-1000 T140AAM (100HP ND) and 4H12AAM (1000HP ND), such as medical equipment

2. Performance rating and overload capacity

Normal Duty (ND): Suitable for larger motors, overload capacity of 110% rated current x 60 seconds

Heavy Duty (HD): Stronger torque, overload capacity of 150% rated current x 60 seconds

Example: 240V model 2030ABM, ND 10HP (30A), HD 7.5HP (25A)

3. Model coding rules (taking “GA80U 2 004 ABM” as an example)

Encoding segment meaning optional values/description

GA80U series identification fixed prefix (Americas region)

2 voltage levels 2=240V, 4=480V, 5=600V, T=12 pulse 480V

004 output current corresponds to ND rated current (unit: A, here it is 4A)

A protection level A=IP00, B=IP20, W=Type 12 flange

B environmental specification B=humidity/dust protection (compliant with IEC 60721-3-3 Class 3C2/3S3)

M EMC filter M=Not used (A=Not used, some models in the document default to no filter)

Single/three-phase input adaptation and component selection

1. Single phase input configuration (requires reduced capacity, some require reactors)

Taking 240V single-phase input as an example, the core parameters are as follows (excerpt from Table 5):

Drive model (GA80U) without reactor (ND/HD) with reactor (ND/HD) Input reactor model (Open)

2004… 1/3HP(1.5A)/1/2HP(2.2A) -/- URX000303

2008… 3/4HP(3.2A)/1HP(4.2A) -/- URX000307

2030… 2HP(6.8A)/5HP(15.2A) -/- URX000323

2. Core supporting components

(1) Reactor and Filter

Component Type Impedance Options Installation Form Core Function Example Model (480V)

DC Bus Reactor 3%/5% Open/Enclosed Type 1 reduces DC side transients and decreases THD URX000033 (3% Open) and URX000215 (3% Enclosed)

AC Input Reactor 3%/5% Open/Enclosed Type 1 suppresses input side harmonics and protects the frequency converter URX000288(3% Open)、URX000551(3% Enclosed)

AC Output Reactor 3% Open/Enclosed Type 1 reduces motor side voltage spikes and is compatible with long cables 05P00620-0014(Open)、05P00620-0016(Enclosed)

EMC Input Filter – Integrated to EN 61800-3 C2 level, reduces electromagnetic interference B84743A00008R176 (8A), B84243A6180Z000 (180A)

(2) Braking unit

Dynamic braking:

3% duty cycle: operates for 3 seconds within a 100 second cycle, with resistance models such as R7504 (240V) and R7508 (480V)

10% duty cycle: operates for 10 seconds within a 100 second cycle, requiring the use of transistor modules (such as CDBR-21100D) and resistors (such as URS000275)

Regenerative braking (R1000):

Suitable voltage: 240V (5-150HP), 480V (5-500HP)

The kit includes: R1000 module, current suppression reactor, power coordination reactor, fuse

Example: R1000-480-50HP kit, including R1000 module model 4A0035AAA

(3) Control and Feedback Attachment

Attachment Type Function Description Model Example

I/O adapter AI-A3: 3 additional analog inputs (13 bits+symbol) AI-A3

Motor feedback card PG-X3: Incremental encoder interface (line driven type) PG-X3

Network Communication Card SI-P3: PROFIBUS-DP Communication Interface SI-P3

Operation keyboard with Bluetooth LCD keyboard: supports mobile APP control-

Remote Cable UWR0052: Keyboard Remote Cable (3m) UWR0052

GA800 configuration package scheme (Type 1/12/3R)

1. Configure the core parameters of the package (taking 480V Type 1 ND as an example)

Rated current (A), nominal HP (ND), basic model, optional power options, optional control options

2.1 G8C1B002 E (standard circuit breaker), C (65kAIC circuit breaker), T+C (PROFINET), T+H (PROFIBUS)

40 30 G8C1B040 P+EX (3% Bus Reactor), F (Input Fuse), T+D (EtherNet/IP), A (Analog Input)

180 150 G8C1B180 M (100kAIC circuit breaker), R (3% Line reactor), T+Q (Modbus TCP), X (PG-X3 feedback)

2. Shell type and environmental adaptation

Shell type, protection level, applicable environmental temperature range, special options

Type 1 IP30 (adapted) cleanroom (such as electronic workshop) -10~+40 ℃ space heater, blower starter

Type 12 IP54 (external heat sink) for dusty environments (such as machinery factories) -10~+50 ℃ external heat sink adapter

Type 3R IP54 (weatherproof) outdoor/humid environment (such as pump station) -10~+50 ℃ (optional 50 ℃ adaptation) independent support leg (UUX000923, 12 inches), lightning arrester

Technical parameters and environment Derating

1. Key technical specifications

Project specification description

Output frequency 0-590Hz

Control mode: open-loop/closed-loop vector, open-loop/closed-loop V/f

Motor compatibility sensitive motor, surface permanent magnet motor (SPM), built-in permanent magnet motor (IPM), synchronous reluctance motor

Standard I/O with 8 digital inputs (24Vdc), 3 analog inputs (0 ± 10V/4-20mA), and 3 relay outputs

Safe Torque Off (STO), SIL3 (IEC 62061), PLe (ISO 13849-1)

Certified UL, CSA, CE, RCM, RoHS, SEMI-F47, IEEE1668

2. Derating rules for the environment

Temperature Derating:

When the ambient temperature is greater than 40 ℃ (Type 1)/greater than 50 ℃ (IP20), for every 1 ℃ increase, the output current will decrease by 2%

Altitude Derating:

≤ 1000m: No capacity reduction

1000-4000m: For every 1000m increase, the output current decreases by 8%

Voltage Derating (altitude>2000m):

Neutral grounding system: No need to reduce capacity

Non neutral grounding system: higher voltage level needs to be selected (such as 600V frequency converter for 480V scenario)

Leave a comment

Your email address will not be published. Required fields are marked *