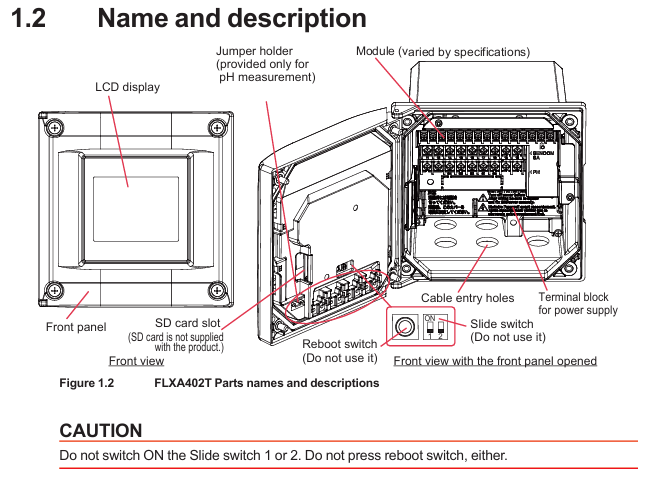

Product positioning

Product type: FLXA402T is a modular design liquid analyzer converter that supports measurement of various parameters such as turbidity (TB820D/TB830D), residual chlorine (FC800D/RC800D), pH value, conductivity (SC), etc. It needs to be used in conjunction with corresponding sensors; Equipped with analog signal output (4-20mA), relay contact output, and digital communication (Modbus RTU/IP) functions, it can upload data to the host system and display locally.

Applicable scenarios: Suitable for industrial process liquid monitoring, supporting indoor and outdoor installation (in accordance with rainproof design), the corresponding sensor module needs to be selected according to the measurement parameters. For example, turbidity measurement needs to be matched with TB series sensors, and residual chlorine measurement needs to be matched with FC/RC series sensors.

Product specifications and model description

1. Core specification parameters

Working environment temperature: -20~+55 ℃ (operation), -30~+70 ℃ (storage); Humidity: 10~90% RH (40 ℃ without condensation)

Waterproof design with protective performance, suitable for both indoor and outdoor use; Outdoor exposure requires a sunshade (/H6/H7 options)

Power supply requirements: AC version (suffix code – A), external 5A or above switch/circuit breaker (compliant with IEC60947-1/3), built-in 250V/2.5A delay fuse (IEC60127 standard)

Communication function supports Modbus RTU (RS-485, suffix – R), Modbus TCP/IP (Ethernet, suffix – E)

Analog IO can choose 2 4-20mA outputs+1 contact input (- N2) or 4 4-20mA outputs+2 contact inputs+1 4-20mA input (- N4), with a maximum load of 600 Ω

Relay outputs 4 sets of SPDT contacts (suffix – WR), including fault safety contacts (S4), configurable for alarm and fault signal output

Grounding requirements: Class D grounding (≤ 100 Ω), protective grounding wire cross-sectional area ≥ 0.75mm ² (CSA certified models 0.75~2.1mm ²)

2. Model and suffix code rules

Model structure: FLXA402T – [Power Supply/Housing] – [First Input] – [Second Input] – [Analog IO] – [Relay Output] – [Digital Communication] – [Other]+[Option Code]. The key code meanings are as follows:

|Code Category | Code Example | Meaning|

|Power supply/enclosure | – A | AC power supply|

|| – B/- D | Aluminum alloy shell (- B: polyurethane coating; -D: High anti-corrosion coating|

|| – AB/- AD | Universal type (- AB: CE/RCM/Chinese standard; -AD: CSA certification)|

|First Input | – CL | SENCOM Protocol Chlorine Sensor (FC800D/RC800D)|

|| – TB | SENCOM Protocol Turbidity Sensor (TB820D/TB830D)|

|Second input | – NN | No second input|

|| – P1/- C1 | pH Sensor/Conductivity (SC) Sensor|

|Analog IO | – N2/- N4 | 2-channel output+1-channel input/4-channel output+2-channel input+1-channel input|

|Relay output | – WR/- NR | with contact output (cleaning/range/fault)/no contact output|

|Digital Communication | – N/- E/- R | No Communication/Ethernet (Modbus TCP/IP)/RS-485 (Modbus RTU)|

|Option code |/U//PM | Universal installation kit (including pipeline/wall installation)/panel installation hardware|

||/H6/H7 | Stainless steel sunshade/Stainless steel+polyurethane coated sunshade|

||/CB4//CD4//CF4 | Catheter adapter (G1/2 x 4/1/2NPT x 4/M20 x 1.5 x 4)|

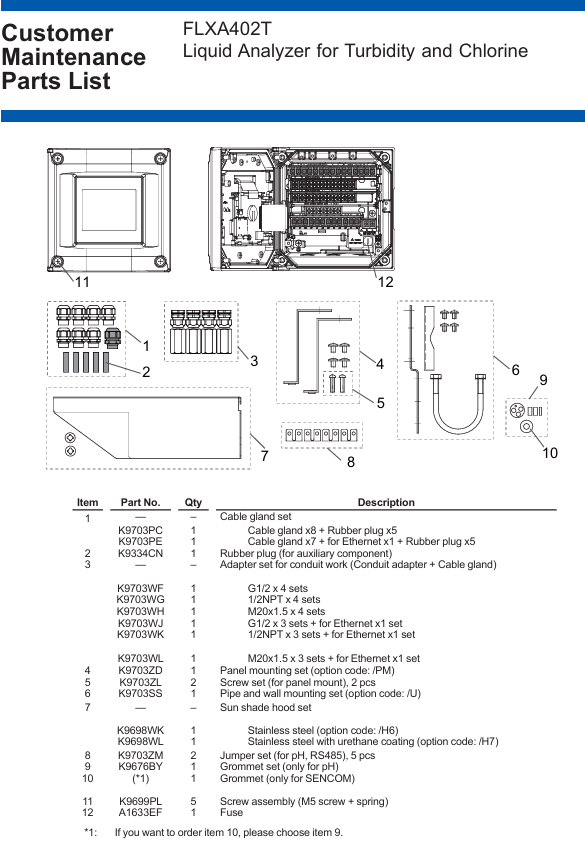

3. Standard and optional accessories

Standard accessories: Cable gland (M20 × 1.5, 8 pieces, Ethernet version includes 1 black Ethernet gland), rubber plug (5 pieces), pH module gasket set, SENCOM module sealing ring, jumper (for pH/RS-485), starter manual (IM 12A01G01-01EN).

Optional accessories: Pipe/wall/panel mounting bracket (/U//PM), sunshade (/H6//H7), conduit adapter (/CB □//CD □/CF □), stainless steel label (/SCT), spare fuse (A1633EF), industrial SD card (A1019NL, 2GB and above).

Installation process and requirements

1. Preparation before installation

Environmental requirements:

Avoid severe vibrations and strong electromagnetic interference (keep away from relays/power switches), and reserve space for cable connections;

Outdoor installation should avoid direct sunlight (when there is no sunshade), and high anti-corrosion coating shell (- D) should be selected for corrosive environments;

The installation surface should be able to withstand a weight of ≥ 8kg (wall installation), and the pipeline installation should be compatible with a nominal 50A pipeline (outer diameter 60.5mm).

Tools and accessories: Prepare torque wrenches (for tightening seals/panel screws), wire strippers, M3/M4 screwdrivers, as well as standard cable seals, jumpers, gaskets, etc.

2. Detailed explanation of installation method

(1) Panel installation (required/PM option)

Drill holes on the panel according to the size (138 × 195mm, tolerance 0+1mm);

Insert the analyzer into the opening and use the matching panel mounting hardware (K9703ZD) to fix it from the inside of the panel. The torque of the four mounting screws is 2N · m.

(2) Wall installation (required/U option)

Drill 3 M8 screw holes on the wall (positioned according to the bracket holes);

Fix the wall bracket (K9703SS) to the wall with M8 bolts, and then use 4 screws to secure the analyzer to the bracket with a torque of 2N · m.

(3) Pipeline installation (required/U option)

Fix the pipeline bracket (including U-bolts) onto the nominal 50A pipeline, ensuring that the bracket is horizontal/vertical;

Fix the analyzer on the bracket with 4 screws, with a torque of 2N · m. If equipped with a sunshade, use the 2 screws above the bracket to fix the sunshade.

3. Disassembly of shielding cover (before wiring)

The high-voltage power terminal and relay module of the analyzer are covered by a shielding cover. Before wiring, the power must be cut off. Loosen the two screws on the shielding cover (marked with a triangle), pinch the circular mark, and pull out the shielding cover (be careful to save the screws to avoid loss); After wiring is completed, the shielding cover needs to be reinstalled to ensure safety and anti-interference.

Wiring operation specifications

1. Installation of cable sealing sleeve

All cable entrances need to be equipped with sealing sleeves (standard M20 × 1.5, compatible with cable outer diameters of 6-12mm), and unused entrances need to be sealed with rubber plugs:

Ordinary cable: Assemble in the order of “sealing sleeve body → sealing ring → nut”, torque 2N · m;

Ethernet cable: Use a black dedicated sealing sleeve (suffix – standard for E models);

Catheter protection: When selecting a catheter adapter (/CB □//CD □//CF □), replace the standard sealing sleeve with a dedicated adapter sealing sleeve (white). The adapter needs to be connected to a flexible catheter to avoid stress damage to the housing.

2. Key wiring process

(1) Power wiring

Confirm power outage, strip off the insulation layer of the power cable (cross-sectional area ≤ 2.5mm ², AWG14), and crimp the solderless terminal;

Connect the AC power supply to terminals “L” (live wire) and “N” (neutral wire), and connect the protective grounding wire to the internal grounding terminal (M4 screw);

After checking the wiring is correct, reinstall the shielding cover. The external power switch/circuit breaker should be labeled as a “power-off device” and installed in an easy to operate position.

(2) Relay output wiring (suffix WR)

The four sets of SPDT contact terminals are defined as follows, connected to the controller/PLC using multi-core cables, with terminal screws of M3 (torque 0.6N · m):

|Terminal number | Contact type | Function|

| — | — | — |

|31/32/33 | S1 (C/NC/NO) | Universal Contact 1 (normally closed/common/normally open)|

|41/42/43 | S2 (C/NC/NO) | Universal Contact 2|

|51/52/53 | S3 (C/NC/NO) | Universal Contact 3|

|71/72/73 | S4 (C/NO/NC) | Fault safety contact (NO → NC when power is off)|

(3) Digital communication cabling

Modbus RTU (RS-485, suffix – R):

Use shielded twisted pair cables (multi-core) to connect terminals 91 (A+, data positive), 92 (B -, data negative), 93 (GND, signal ground), and 94 (SHIELD, shielding layer);

When terminal matching is required at both ends of the bus, use the standard jumper to connect terminals 91 and 95 (with a built-in 110 Ω resistor). Unused jumpers need to be stored in the jumper bracket on the inside of the panel.

Modbus TCP/IP (Ethernet, suffix – E):

Use CAT5 and above shielded twisted pair (STP) cables to make RJ45 connectors (supporting direct/cross connections);

Insert the network cable into the Ethernet interface of the analyzer, fix the cable with a black dedicated sealing sleeve, and ground the shielding layer.

(4) Simulate IO wiring

4-20mA output: Use shielded cables, connect terminals 61 (mA1+)/62 (mA1-), 65 (mA2+)/66 (mA2-), etc., and connect the shielding layer to terminal 63 (or 89, – N4 model);

4-20mA input (- N4 model): Connect terminals 87 (AI+) and 88 (AI -), and connect the shielding layer to terminal 89;

Contact input: Connect terminals 21 (DI1)/24 (DI2, – N4 model) and 22 (COM), used to initiate cleaning cycles or switch ranges, with shielding layer connected to terminal 63.

3. Sensor wiring

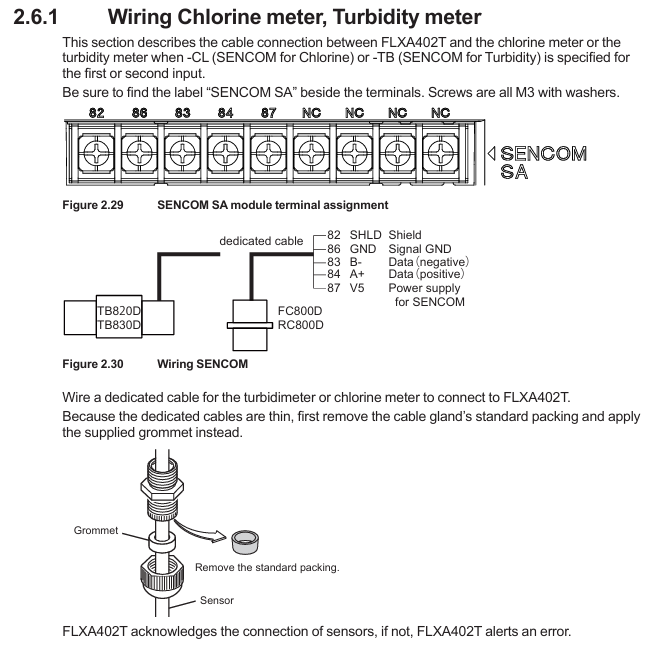

(1) SENCOM sensor (- CL/- TB)

Use sensor specific cables, remove the cable sealing sleeve and standard sealing ring, and replace with standard grommet (suitable for thin cables);

Connect according to the terminal markings “SHLD (shielding), GND (signal ground), B – (data negative), A+(data positive), V5 (power supply)”, with terminal screw M3 (torque 0.6N · m);

The sensor adopts single ended grounding to avoid interference caused by grounding at both ends.

(2) PH sensor (- P1)

Conventional pH sensor connection terminals 13 (REF, reference electrode), 15 (Glass, measuring electrode), 11/12 (Temp, temperature compensation), 14 (Solution ground), shielding layer connected to 16/17;

Low impedance reference electrodes require the installation of jumpers (2 standard), and unused jumpers should be stored in the jumper bracket; Special double glass electrodes do not require jumper wires.

(3) Conductivity (SC) sensor (- C1)

The 4-electrode sensor is directly connected to terminals 11 (Temp+), 12 (V -), 13 (I -), 15 (V+), and 16 (I+);

Two electrode sensors require one jumper wire (standard) to be connected between terminals 13-14 and 15-16 to ensure normal signal transmission.

Inspection and maintenance

1. Check after wiring

Before powering on: Confirm that all wiring is correct, the shielding cover has been reinstalled, and the panel screws are evenly tightened (torque 1.5~1.6N · m, electric screwdriver speed ≤ 400rpm);

After power on: Check that the LCD display screen starts normally, there are no fault alarms (such as sensors not connected or wiring errors), and communication and analog output signals are normal.

2. Regular maintenance

Daily inspection: Check the panel sealing and cable sealing sleeve for integrity and no moisture intrusion every week;

Regular maintenance: Check the grounding resistance (≤ 100 Ω), fuse status, and clean the casing every 6 months (using a soft cloth and prohibiting the use of corrosive solvents);

Accessory replacement: Fragile parts such as fuses (A1633EF) and rubber seals (K9334CN) require Yokogawa certified accessories, and power off operation is required during replacement.

3. Fault handling prompts

If there is a communication failure, check whether the RS-485/Ethernet wiring and terminal resistance are correct;

When simulating abnormal output, check the load resistance (≤ 600 Ω), whether the wiring is loose, or calibrate the output through the converter menu;

When the sensor is unresponsive, confirm that the sensor cable shield is grounded and the terminal wiring corresponds, and refer to the sensor manual to troubleshoot the sensor itself.

Key precautions

Safety regulations: All wiring must be powered off, power cables must comply with UL 2556 VW-1 or equivalent flame retardant rating, and protective grounding wires cannot be omitted;

Anti interference: Analog signals, digital communication, and power cables need to be wired separately, shielded cables should be grounded at one end (analyzer side), and avoid parallel laying with strong electrical cables;

Modular maintenance: Only authorized personnel from Yokogawa can perform module repairs/replacements (such as pH module K9704EB, SC module K9704FB). Unauthorized operations will result in loss of warranty eligibility;

Environmental protection: For outdoor installation, it is necessary to confirm that the sunshade/conduit is properly adapted to prevent rainwater and corrosive gases from entering and extend the service life of the equipment.

Leave a comment

Your email address will not be published. Required fields are marked *