Product positioning and core features

ControlMaster CM10 is a universal PID process controller with 1/8 DIN specifications, integrating display, control, and communication, suitable for industrial process control scenarios. Its core advantages include:

Full color visualization: 5.5 cm TFT full-color display screen, supporting custom interface, clearly displaying process parameters, alarms, and diagnostic information.

Flexible and Scalable: Hardware and software functions can be scaled to meet different control needs through function keys and templates.

Multi mode control: supports switch control, time proportional control, analog PID, motor valve control, and branch output control.

High protection design: The front panel reaches IP66/NEMA 4X protection level, suitable for harsh industrial environments.

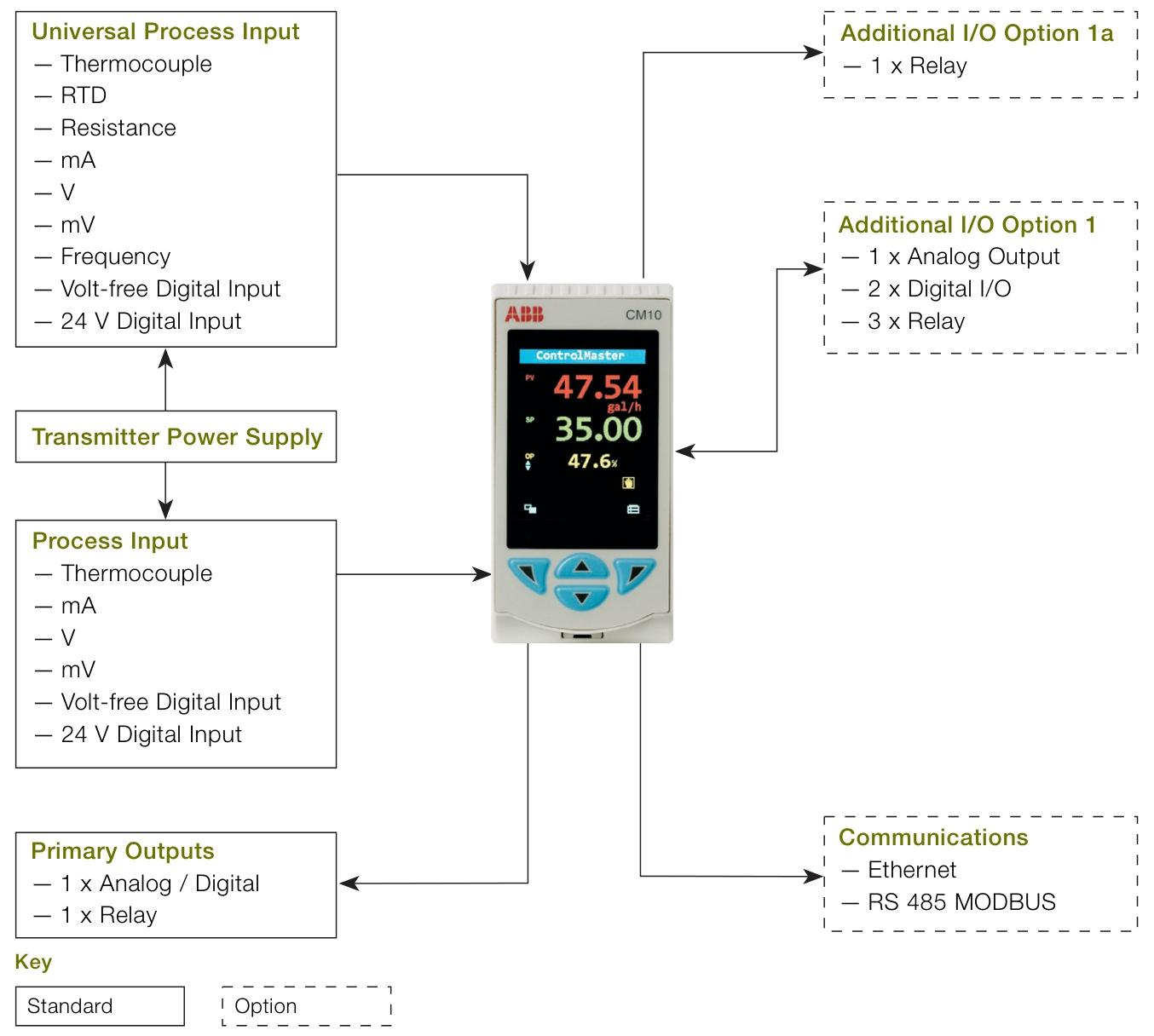

Hardware and Input/Output Configuration

1. Input type

Universal process input (1-channel standard): Supports thermocouples (B/E/J/K and other types) RTD(Pt100)、 Resistance, current (0-50mA), voltage (0-25V), frequency, digital input (dry contact/24V).

Non universal input (1-channel standard): voltage, current, thermocouple, etc., suitable for specific sensors.

Accuracy: Thermocouple accuracy ± 0.1% or ± 0.5 ℃ (such as K-type thermocouple -100~1300 ℃ range), RTD accuracy ± 0.5 ℃.

2. Output configuration

Control output: 2 channels (1 standard+1 optional), configurable as analog (0-20mA, 750 Ω load) or digital pulse, supporting split output (such as heating/cooling dual control).

Relay output: 1 standard+3 optional, contact capacity 5A/240V (at 40 ℃), supports NO/NC switching.

Digital I/O: 2 selectable channels, programmable as input (dry contact/24V) or output (open collector, 30V/100mA).

Control functions and software features

1. Control strategy

PID control: supports AutoTune, gain scheduling (automatic switching of 3 sets of PID parameters), and branch output (such as single loop heating/cooling).

Remote control: Supports external signal switching between automatic/manual modes, with preset output values (such as automatic valve opening during cleaning cycles).

Setpoint selection: Switch local/remote setpoints (such as multi-stage temperature control) through digital signals.

2. Advanced features

Alarm and Logic: 8 process alarms (high and low limits, latch), 2 real-time alarms (timed trigger), 8 sets of logic equations (OR/AND, etc.).

Mathematics and Linearization: 8 mathematical modules (addition, subtraction, multiplication, division, square root, maximum value, etc.), 2 sets of 20 point custom linearization (adapted to nonlinear liquid level volume conversion).

Delay timer: 2 programmable delay timers, supporting event sequence control.

Communication and integration capabilities

Ethernet (optional): Supports MODBUS TCP, web server (remote monitoring), and email alerts (up to 3 recipients).

RS 485 MODBUS (optional): Supports RTU protocol, with a maximum baud rate of 115kbps and galvanic isolation.

PC configuration: Offline configuration through Asset Vision Basic software, with configuration files transmitted via infrared port.

Application templates and scenarios

Single loop control: suitable for single parameter adjustment of heat exchanger temperature, flow rate, etc., supporting remote setpoint switching.

Automatic/Manual Station: As a backup controller for PLC/DCS, it takes over control when detecting low signals or faults.

Simulated backup station: Automatically switches when the main controller fails to maintain process stability (such as critical flow control).

Technical specifications and certification

Power supply: 100-240V AC (± 10%) or 10-36V DC, power consumption ≤ 10W.

Environment: Working temperature 0-55 ℃, humidity 5-95% (no condensation), front panel IP66 protection.

Certification: Compliant with EN 61010-1 and cULus standards, EMC meets industrial environmental requirements.

Leave a comment

Your email address will not be published. Required fields are marked *