The official project planning manual for Bosch Rexroth CDH1/CGH1/CSH1 series milling machine hydraulic cylinders revolves around product technical parameters, installation configuration, seal selection, accessory matching, and safety specifications. It specifies key specifications such as rated pressure of 250 bar, piston diameter of 40-320 mm, and maximum stroke of 6 m. It provides detailed requirements for 6 installation methods, selection of multiple types of sealing systems, and adaptation requirements for position measurement and control interfaces (IO Link/Profinet, etc.), as well as practical points such as tightening torque, anti buckling calculation, and corrosion resistance level, providing comprehensive technical guidance for equipment selection, installation, commissioning, and maintenance.

1、 Basic Information

Covering products

CDH1 series: Single piston rod differential cylinder, supports 6 installation methods, suitable for conventional hydraulic scenarios.

CGH1 series: Double piston rod cylinder, installation methods include MF3/MT4/MS2, suitable for bidirectional symmetrical loads.

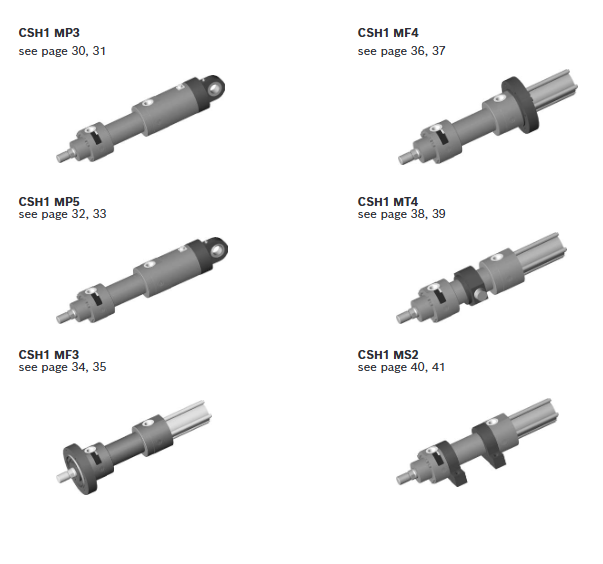

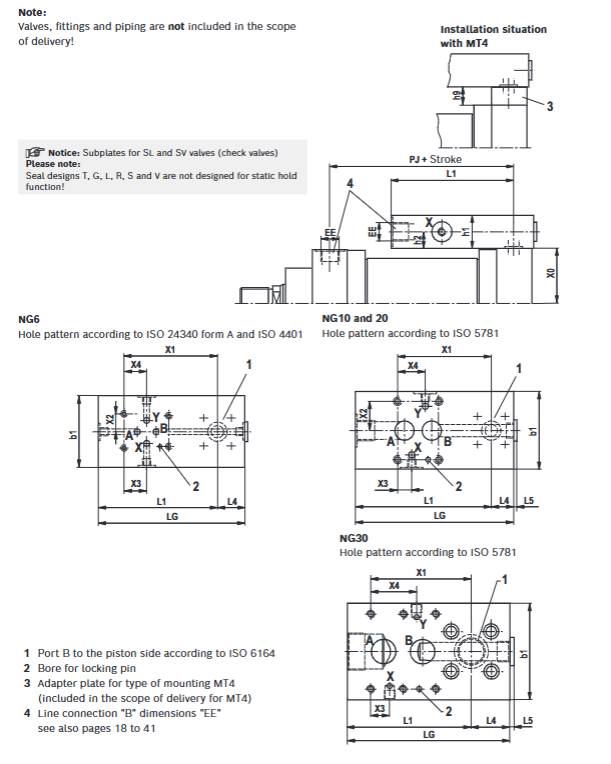

CSH1 series: differential cylinder with magnetostrictive position measurement system, supporting multiple digital/analog signal outputs.

Document type and purpose: Project planning manual, used to guide product selection, mechanical/electrical integration, installation, commissioning, and maintenance.

Core applicable scenarios: milling machines, industrial hydraulic equipment, heavy-duty transmission systems, etc., suitable for various hydraulic media such as mineral oil and water ethylene glycol.

2、 Core technical parameters

(1) Summary of Key Specifications

Remarks on the numerical range of parameter items

Rated pressure 250 bar Static test pressure 375 bar

Piston diameter (Ø AL) 40-320 mm in accordance with ISO 3320 standard

Piston rod diameter (Ø MM) 22-220 mm matches with piston diameter

The maximum travel of 6 meters needs to be confirmed in conjunction with anti buckling calculations to allow for travel

Hydraulic media HL/HLP/HFA/HFC/HFDR/HFDU correspond to different sealing systems

The temperature range of the medium is -20 ℃~+120 ℃, adjusted according to the sealing type

Cleanliness requirements ISO 4406 20/18/15 require a matching filtering device

(2) Travel speed limit

Piston diameter (mm) Interface specification Maximum travel speed (m/s)

40 G1/2 0.31

63 G3/4 0.28

100 G1 0.20

200 G1 1/2 0.11

320 G1 1/2 0.04

3、 Installation and fastening requirements

(1) Classification of installation methods and applicable scenarios

Installation method type applicable scenarios

MP3 base rotating earrings require swinging load connection

Scenario of MP5 Base Self Adjusting Fork Head Compensation Installation Deviation

MF3 head circular flange fixed installation, axial load

MF4 base circular flange body integrated installation

MT4 Ear Shaft Installation Heavy Load Swing Scenario

MS2 Foot Seat Installation Horizontal/Vertical Fixed Installation

(2) Key tightening torque (bolt grade 10.9)

Piston diameter (mm) Head/base bolt specifications Tightening torque (Nm)

40 M8 23

100 M12 100

200 M20 410

320 M30 1500

4、 Sealing system and selection

(1) Sealing design types and compatible media

Sealing type adapted to the core characteristics of the medium

M/L/R Mineral Oil HL/HLP/HFA Standard Type/Low Friction/Heavy Industrial Grade

G/T mineral oil+water ethylene glycol HFC servo grade low friction

V/S phosphate ester HFDR/polyol ester HFDU resistant to chemical corrosion

A/B Mineral Oil/Water Ethylene Glycol Lip Seal Kit

(2) Core principles of selection

Medium matching: Select the corresponding sealing design based on the type of hydraulic oil (mineral oil/water-based/synthetic oil).

Temperature adaptation: Choose conventional sealing for -20 ℃~+80 ℃, and high-temperature resistant type (such as V/S) for+80 ℃~+120 ℃.

Working condition requirement: Avoid T/G/L/R/S/V type seals when maintaining static pressure for more than 10 minutes.

5、 Position measurement and control interface

(1) Control interface type

Interface type signal output applicable scenarios

Proximity switch PNP normally open signal simple terminal detection

IO Link Digital Signal (32-bit Position Value) Industry 4.0 Networking

Profinet RT/IRT protocol high-precision synchronous control

SSI 1/5 μ m resolution high-precision position feedback

(2) Key parameters

Supply voltage: 12-30 VDC (IO Link/Profinet)

Protection level: IP67 (after connector installation), IP68 (cable outlet)

Transmission rate: Profinet maximum 100 MBit/s, IO Link 230.4 kBaud

6、 Key points of safety and maintenance

Pressure safety: The maximum working pressure should not exceed the rated value, and pressure amplification caused by area ratio should be considered.

Buckling prevention requirement: When installed vertically, the allowable travel must be calculated according to Euler’s formula, with a safety factor of 3.5.

Corrosion protection: Choose CP3 (conventional) to CP7 (offshore high salt spray) coatings according to the environment.

Medium requirements: The optimal viscosity is 20-100 mm ²/s, with a minimum of 12 mm ²/s to avoid impurity contamination.

Leave a comment

Your email address will not be published. Required fields are marked *