B&R Power Panel 300/400 Touch Screen

Core positioning and core advantages

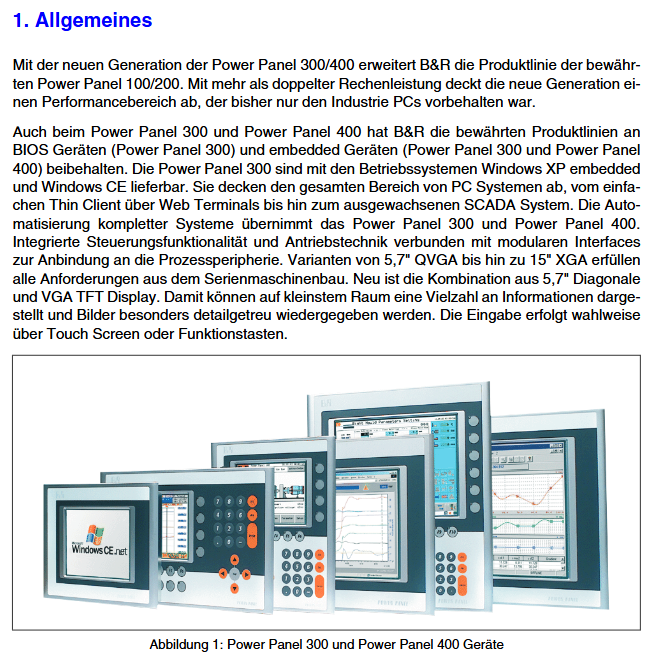

The B&R Power Panel 300/400 series touch screen is a human-machine interaction terminal designed specifically for industrial automation scenarios, covering multi scenario requirements from basic control to complex automation. Its core advantages focus on three dimensions: high compatibility, industrial grade reliability, and flexible scalability, which can be summarized into six key features:

Dual product line adapts to diverse needs: divided into Power Panel 300 (basic type) and Power Panel 400 (extended type). The former focuses on basic human-computer interaction, while the latter supports 1-2 aPCI slots, expandable communication modules or function cards, meeting the needs from simple data display to complex control integration.

Industrial grade environmental tolerance: The front side protection level reaches IP65/NEMA 250 Type 4X, dustproof and water-resistant; Working temperature coverage -20~+50 ° C (some models support -20~+70 ° C storage), anti vibration (2-200Hz, 0.5-2g amplitude), anti impact (15-30g, 11-15ms half sine wave), suitable for harsh industrial sites.

Flexible hardware configuration: equipped with Geode LX800 500MHz processor, supporting 128-512MB DDR SDRAM memory and Type I CompactFlash storage expansion; The display size covers 5.7 inches (QVGA/VGA) to 15 inches (XGA), including various screen types such as monochrome LCD, color LCD, color TFT, etc. Some models integrate resistive touch screens (Elo Accu Touch/Unze technology), with a light transmittance of 80% ± 5%.

Rich communication and interfaces: standard 10/100Mbps Ethernet (Intel 82551ER controller), RS232 serial port (16C550 compatible, maximum 115kBaud), 2 USB 2.0 interfaces (maximum 500mA power supply per port); The Power Panel 400 additionally supports aPCI slots and can expand fieldbus modules (such as CAN, Profinet, etc.) to meet the interconnection needs of industrial equipment.

Dual Run Mode Switching: Supports OS Mode (regular operating system startup, such as Windows CE/XP Embedded) and AR Mode (automatic runtime startup, adapted to B&R Automation Runtime) through BIOS Boot Mode switch, meeting the startup logic requirements in different control scenarios.

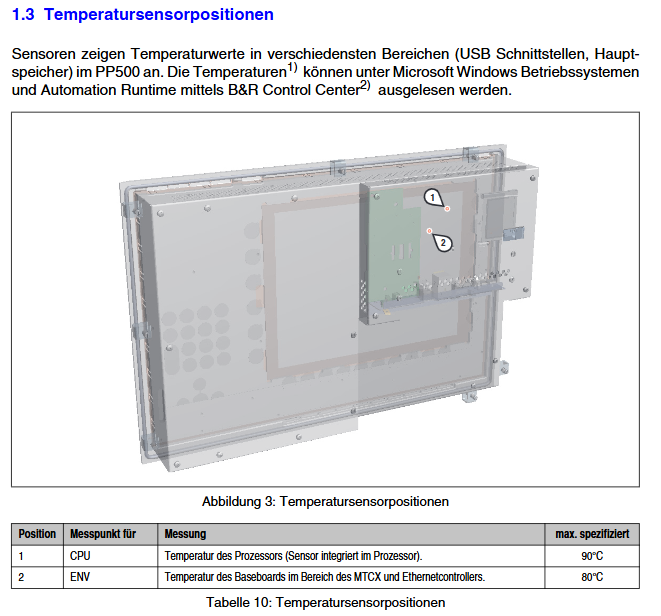

Convenient maintenance and diagnosis: equipped with Mode/Mode dip switch (supports Boot/Mode/Dyn. Mode/Diagnosis four modes), status LED (Power/User/CF indicator light), external Reset/Power button; Support reading key data such as CPU and ambient temperature through B&R Control Center, enabling fast and efficient fault location.

Core components and functional details of the product

(1) Core hardware components and classification

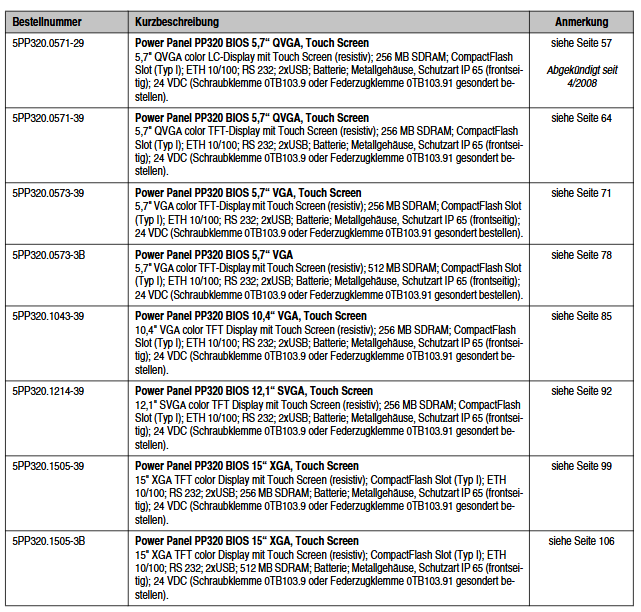

According to functional positioning and hardware configuration, products are mainly divided into three categories, and the differences in core parameters of each model are shown in the following table:

Product Category Represents Model Core Configuration Differences Applicable Scenarios

Power Panel 300 (BIOS version) 5PP320.0571-29 and 5PP320.1505-39 only support BIOS startup and do not have an aPCI slot; The memory is mostly 256MB, with some models (such as 5PP320.1505-3B) reaching 512MB; the display size is 5.7-15 inches, and some scenarios include touch screen basic data monitoring, simple device control, and no need for extended functions

Power Panel 300 (Automation Runtime Edition) 4PP320.0571-01, 4PP381.1043-31 pre installed with Automation Runtime system, without aPCI slot; 128MB memory, supports CompactFlash storage; Some models (such as 4PP381.1043-31) integrate 28 function keys with LED indicator lights that need to be linked with the B&R automation system, focusing on operational control scenarios

Power Panel 400 (Automation Runtime Edition) 4PP420.0571-45, 4PP451.1043-75 supports 1-2 aPCI slots and expandable communication modules; 128MB memory (some older versions 64MB), 512kB SRAM (battery backup, supports data saving in case of power failure); Integrate more function keys (such as the 4PP451 series with 16 function keys and 6 soft keys) into complex automation systems, requiring the expansion of fieldbus and multi device linkage control scenarios (such as production line control and equipment cluster monitoring)

(2) Key functional characteristics

1. Display and input functions

Screen performance: Different screen sizes have differentiated design parameters, such as 5.7-inch QVGA color TFT (4PP320.0571-35) with a contrast ratio of 350:1 and brightness of 500cd/m ², and 15 inch XGA color TFT (4PP320.1505-31) with a contrast ratio of 400:1 and brightness of 250cd/m ², all of which support screen rotation function and are suitable for horizontal/vertical installation requirements.

Touch and buttons: The resistive touch screen supports 12 bit precision and has a click life of over 10 ⁶ times; The function keys adopt industrial grade design, with a pressure range of 1 ± 0.3~3 ± 0.3N. Some models (such as the 4PP481 series) include plug-in key strips with customizable labels for easy on-site identification and maintenance.

2. Power supply and protection design

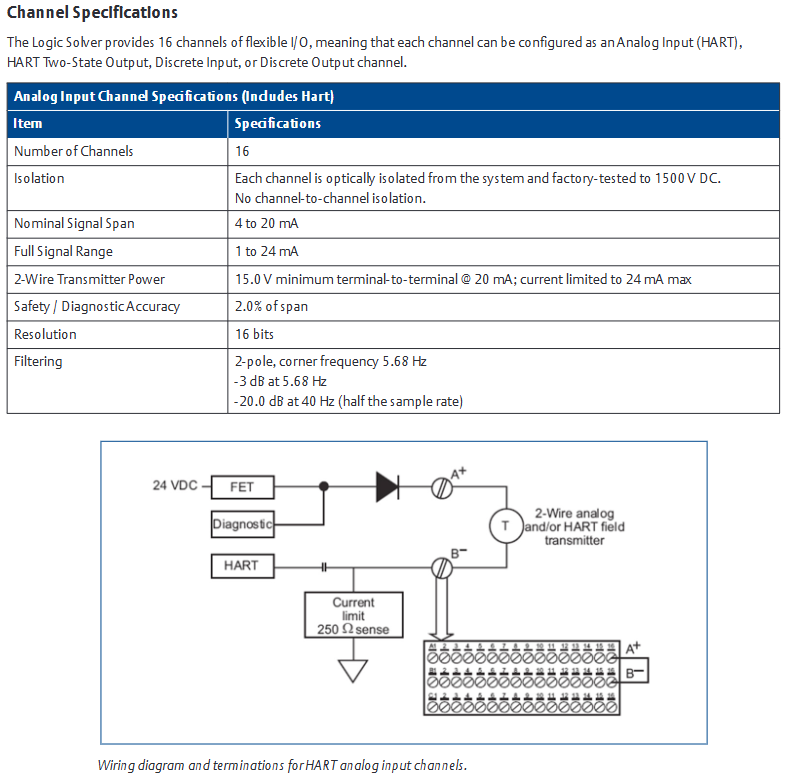

Power supply and isolation: Input voltage 18-30VDC, supporting reverse polarity protection; Each channel is optically isolated from the system (1500VDC test), and the USB interface is protected by a “USB current limit switch” (maximum 500mA per port) to prevent external device overload damage.

Heat dissipation and durability: adopting passive heat dissipation (heat sink) and fanless design to reduce dust accumulation; The shell is made of anodized aluminum material, and the sealing strip on the front side is waterproof, suitable for long-term industrial operation.

3. Diagnostic and maintenance functions

Status monitoring: Real time display of device status through LED indicator lights (Power light green=power supply normal, red=standby; CF light yellow=storage read/write in progress); Support reading CPU temperature, memory usage, and other data through B&R ADI (Automation Device Interface), triggering alarms in case of abnormalities.

Convenient maintenance: CompactFlash slot with locking buckle and ejector, supports power-off replacement; BIOS supports the “restore default value” function (set the Mode/Mode switch to 00 and reset three times), simplifying the fault recovery process.

Hardware specifications and environmental parameters

(1) General Electric and Physical Specifications

Category parameter details (universal type, some models have differences)

Processor Geode LX800 500MHz, 32-bit x86 architecture, supports MMX/3D Now! instruction set

128-512MB DDR SDRAM memory, 8MB shared video memory (for graphics card)

Storage Type I CompactFlash slot (supports 64MB-16GB SLC NAND Flash)

Communication interface 1 x Ethernet (RJ45, 10/100Mbps), 1 x RS232 (9-pin D-Sub), 2 x USB 2.0 (Type A)

Power input 18-30VDC, rated current 0.45-1.25A (depending on model), power 10-30W

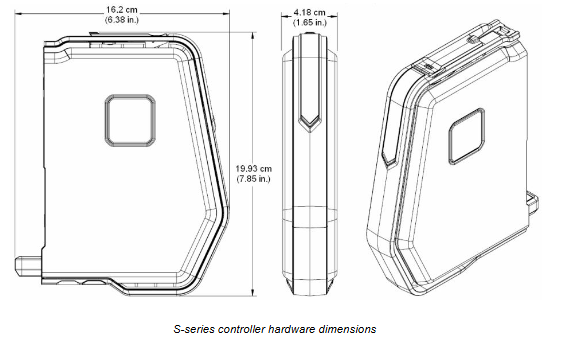

Physical size 5.7 inches model: 212 × 156 × 55.5mm (width × height × depth); 15 inch model: 435 × 330 × 71.5mm

The weight of the 5.7-inch model is approximately 1.4-1.7kg, and the 15 inch model is approximately 6.3kg (excluding expansion modules)

(2) Environmental and Protection Parameters

Category parameter details

Working temperature 0~+50 ° C (some models such as 4PP320.1043-31 support -20~+50 ° C)

Storage temperature -20~+70 ° C

Relative humidity of 5%~95% (no condensation), in compliance with ISA-S71.04-1985 G3 level pollution protection

Protection level: Front side IP65, Rear side IP20 (requires insertion of CF card or aPCI module)

Anti vibration operation: 2-9Hz (1.75mm amplitude), 9-200Hz (0.5g); Storage: 2-8Hz (7.5mm amplitude), 8-200Hz (2g)

Anti impact operation: 15g (11ms); Storage/Transportation: 30g (15ms)

The maximum altitude is 3000m (for every 1000m increase, the maximum working temperature decreases by 1 ° C)

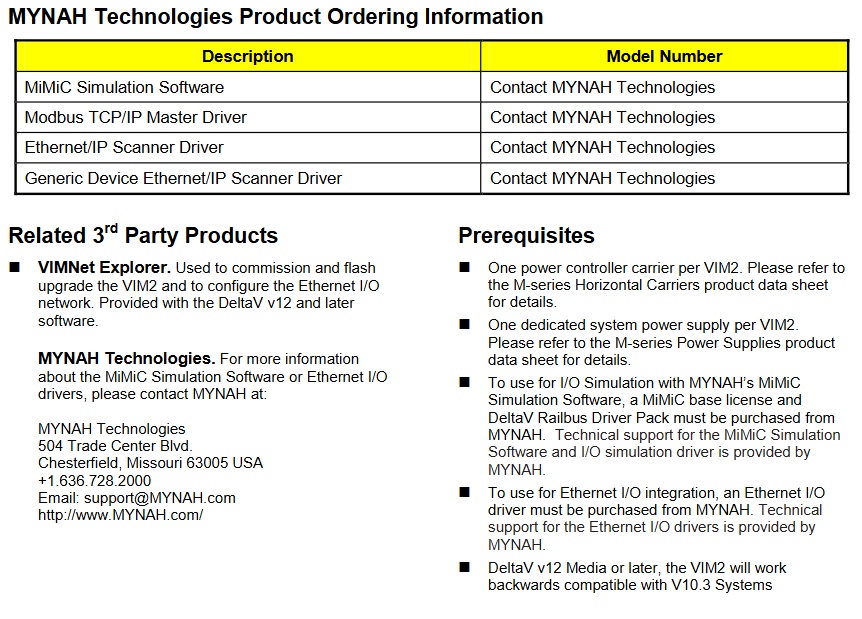

Order information and system compatibility

(1) Core Product Order List (Key Models)

Product Category Model Description Remarks

Power Panel 300 (BIOS version) 5PP320.0571-29 5.7-inch QVGA color LCD with touch screen, 256MB memory including 1 CF slot, no aPCI slot

5PP320.1505-39 15 inch XGA color TFT with touch screen, 256MB memory, front side IP65, supports screen rotation

Power Panel 300 (AR version) 4PP320.1043-31 10.4-inch VGA color TFT, with touch screen, 128MB memory compatible with B&R Automation Runtime, including 6 fixed buckles

4PP381.1043-31 10.4-inch VGA color TFT with touch screen and 28 function keys supporting aPCI expansion, suitable for complex operation scenarios

Power Panel 400 (AR version) 4PP420.0571-75 5.7-inch QVGA color TFT, with touch screen, 1 aPCI slot, 128MB memory, including lithium battery (3V/950mAh)

4PP451.1043-75 10.4-inch VGA color TFT with 10 soft keys+28 function keys and 2 aPCI slots, compatible with multi bus integration

Spare part 0AC201.91 lithium battery (3V/950mAh, 4 pieces/box) for RTC clock and SRAM data backup

5CFCRD.2048-04 2GB Type I CompactFlash Card (SLC NAND) industrial grade storage, compatible with all models

0TB103.9 24V 3-pin screw terminal power plug needs to be ordered separately for power connection

(2) System compatibility requirements

Software compatibility: Supports Windows CE 5.0/6.0 (Professional/ProPlus version) Windows XP Embedded(Feature Pack 2007)、Windows Embedded Standard 2009; Automation Runtime needs to be configured with B&R Automation Studio software.

Hardware compatibility: aPCI slots only support B&R System 2005 series modules (such as CANopen, Profinet modules); CompactFlash should use industrial grade SLC type (recommended original B&R model to avoid compatibility issues); External devices must comply with USB 2.0 specifications or RS232 protocol (such as barcode scanners, printers).

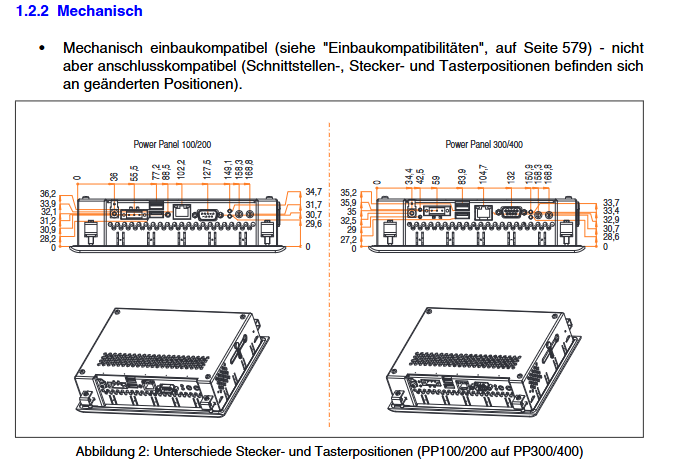

Installation compatibility: Compatible with the mechanical installation dimensions of Power Panel 100/200 (with the same hole size), but with different interface positions (such as rotating the power plug 180 °), requiring rewiring.