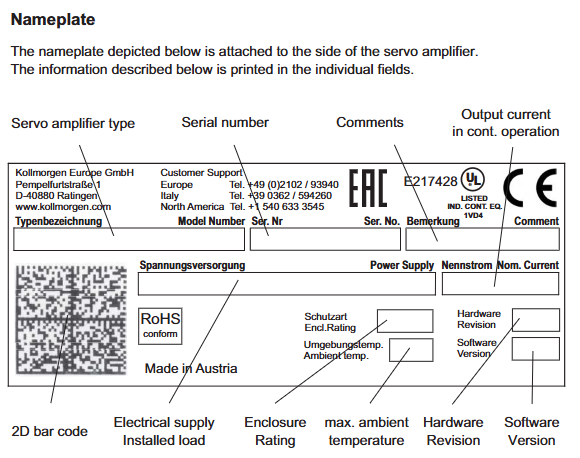

KOLLMORGEN Saia PCD Series I/O Modules

Basic Information

Core scope

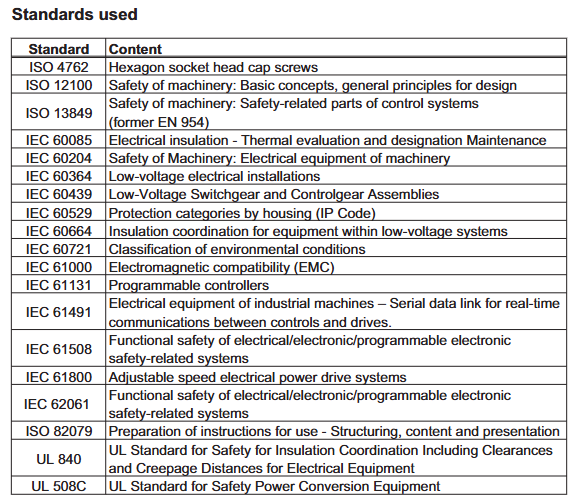

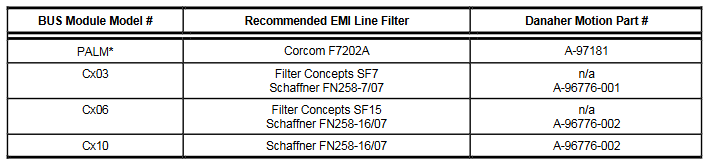

Covering five major categories of modules: digital input/output modules, analog input/output modules, digital hybrid I/O modules, counting and motion control modules, and special function modules (such as weighing and thermocouple modules), while distinguishing the differences between PCD2 and PCD3 series modules (such as the addition of cage spring terminals and higher anti-interference levels in PCD3), supporting industrial standard signal types such as 24V DC/115-230V AC input and 0-10V/0-20mA analog signals. Some modules have electrical isolation (up to 500V isolation voltage) and short-circuit protection functions.

Version and compatibility

Document historical version updates focus on module function supplementation (such as adding PCDx.B160/W380/G200 modules in ENG07), parameter correction (such as adjusting product status section in ENG09), and the latest version of ENG10 optimizes PCD3.A810/W800 power consumption parameters; In terms of hardware compatibility, the PCD2 module needs to be compatible with CPU hardware version H or above, while the PCD3 module supports RIO remote IO systems (some modules such as H210/H31x are currently not compatible).

Core module classification and technical parameters

(1) Core parameters of PCD2 series modules

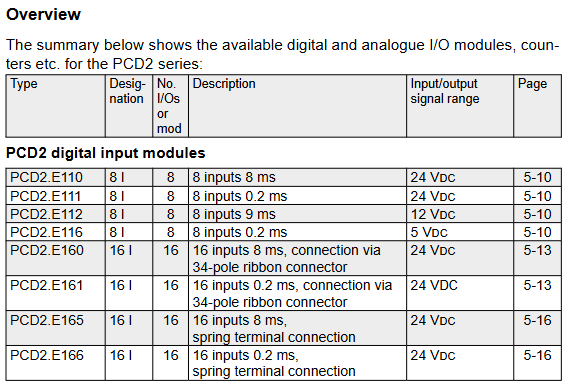

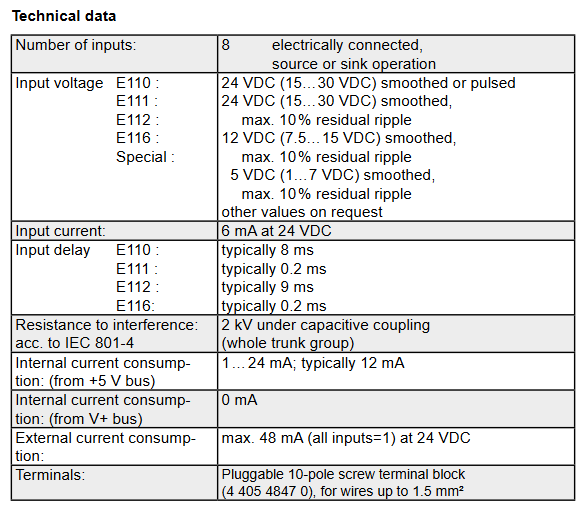

1. Digital input module

Module model, number of input channels, signal range, response time, electrical isolation, wiring method

PCD2.E110 8 24V DC 8ms without 10 pole screw terminal

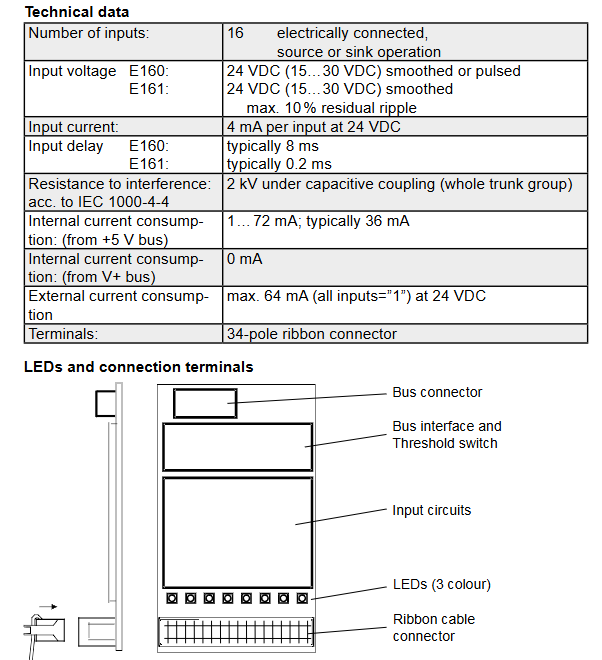

PCD2.E160 16 24V DC 8ms without 34 pole ribbon cable connector

PCD2.E500 6 115-230V AC 10ms (pull in)/20ms (release) with (2.5kV optocoupler isolation) 10 pole screw terminal

PCD2.E610 8 24V DC 10ms with (1kV AC isolated) 10 pole screw terminal

2. Digital output module

Module model, output channels, rated current signal range, protection function

PCD2A300 6 2A/channel 10-32V DC without short circuit protection, requires external 12.5A fast melting

PCD2.A400 8 0.5A/channel 5-32V DC without short circuit protection, load resistance ≥ 48 Ω

PCD2.A200 4 2A/channel (relay) 250V AC/50V DC varistor+RC component contact protection

PCD2.A410 8 0.5A/channel 5-32V DC electrical isolation (1kV AC), without short circuit protection

3. Analog input module

Module model, channel number, resolution, signal type, accuracy (25 ℃)

PCD2.W100 4 12 bit 0-10V/-10~+10V ± 0.1% ± 1LSB

PCD2.W220 8 10 bit Pt/Ni1000 temperature sensor ± 3LSB

PCD2.W305 7 12 bit 0-10V ± 0.15%

PCD2.W745 4 16 bit J/K type thermocouple ± 0.4 ℃ (0-100 ℃)

4. Counting and motion control module

Module model, function, highest frequency, number of axes, encoder support

PCD2.H100 pulse counting 20kHz incremental encoder (phase A/B)

PCD2.H150 SSI interface 500kHz 1 absolute encoder (SSI protocol)

PCD2.H210 stepper motor control 19.45kHz 1 24V DC encoder

PCD2.H310 servo motor control 100kHz 1 24V DC incremental encoder

(2) Core Upgrade of PCD3 Series Modules

The PCD3 series optimizes terminal design, anti-interference performance, and functional expansion based on PCD2, with the following core differences:

Module type: PCD2 series features: PCD3 series upgrade points

The screw terminal of the digital input module (with a maximum wire diameter of 1.5mm ²) has added cage spring terminals (such as 24 pole terminals for E165, supporting a wire diameter of 1.0mm ²), and the anti-interference level has been raised to IEC 61000-4-4 (± 2kV capacitive coupling)

The 8-bit resolution of the analog output module is mainly increased from the W6x0 series to 12 bit resolution, with an output delay of ≤ 10 μ s and support for -10~+10V bipolar signals

The motion control module only supports local IO H32x series, supports DSP processors, realizes S-curve trajectory planning, and supports 250kHz encoder input

Wiring compatibility only supports fixed terminals, supports PCD3.K010/K106 connection cables, and modules can be directly cascaded (maximum distance of 2.5m)

(3) Electrical isolation and safety characteristics

Isolation type and level

Digital isolation module (such as PCD2. E610/PCD3. E610): using optocoupler isolation, isolation voltage 1000V AC (1 minute), no isolation between channels, suitable for strong interference environments (such as near frequency converters);

Analog isolation module (such as PCD2. W3x5/PCD3. W3x5): adopts DC/DC isolation, isolation voltage of 500V, supports 7-channel analog signal acquisition, suitable for signal isolation in process control (such as chemical equipment).

Safety Specifications

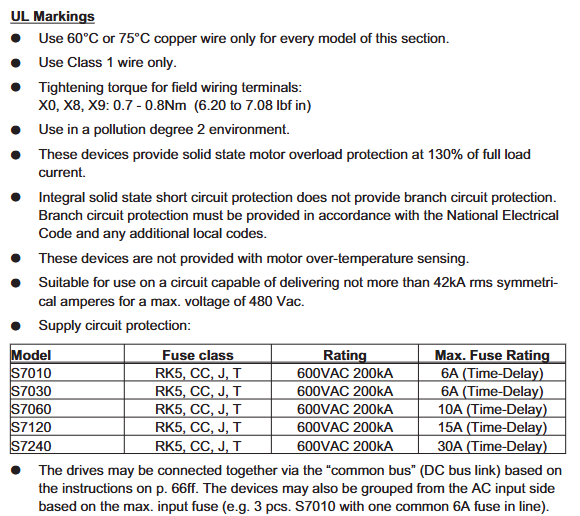

High voltage modules (such as PCD2, E500, PCD3, E500115-230V AC input) need to be separately equipped with fuses (1A/250V), and are prohibited from being connected together with low voltage signals (≤ 50V);

The contact protection of relay output modules (such as A200/A210) needs to be matched with the load type: inductive loads require external current diodes, and capacitive loads require series current limiting resistors to avoid contact arc damage.

Installation and wiring specifications

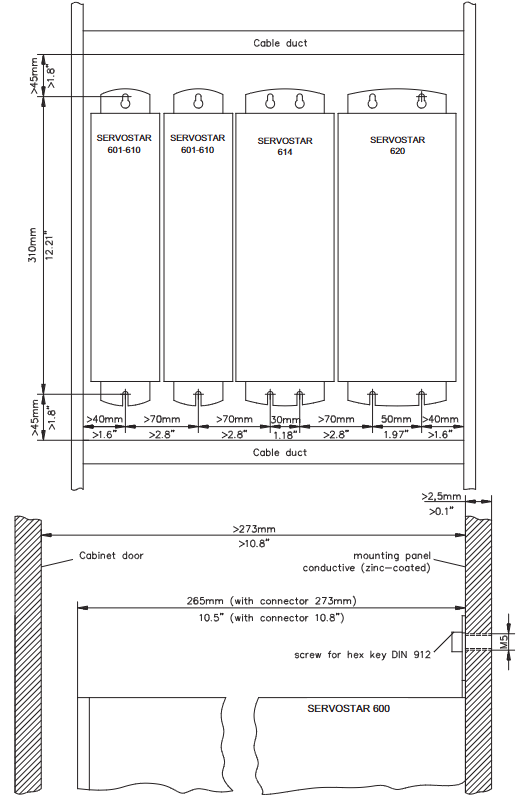

(1) Mechanical installation requirements

Installation environment

Working temperature: 0-55 ℃ (if it exceeds 40 ℃, the output current should be reduced by 2% for every 1 ℃ increase);

Protection level: IP20 (IEC 60529), to be installed inside the control cabinet to avoid dust and condensation water;

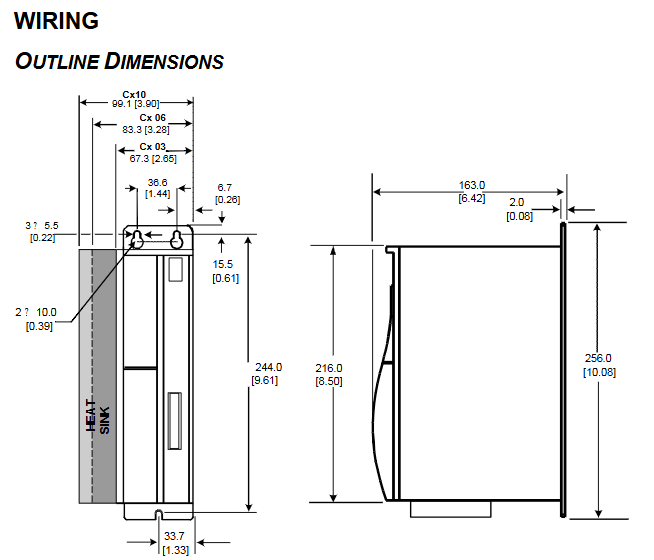

Installation spacing: Reserve ≥ 25mm heat dissipation space on both sides of the module for vertical installation (allowing ± 15 ° tilt), and additional fixation is required for heavy-duty modules (such as PCD2. H32x).

Terminal installation

Screw terminal: torque 0.7-0.8Nm (compatible with M3 screws), wire diameter 0.5-2.5mm ²;

Cage type spring terminal (PCD3 specific): No tools required, directly insert the wire (maximum 1.0mm ²), press the release button when pulling out, and increase wiring efficiency by 30%.

(2) Key specifications for electrical wiring

Power supply and grounding

Digital module: 24V DC power supply needs to be supplied separately (ripple ≤ 10%), PE wire cross-section ≥ 1.5mm ², single point grounding is used (grounding resistance ≤ 1 Ω);

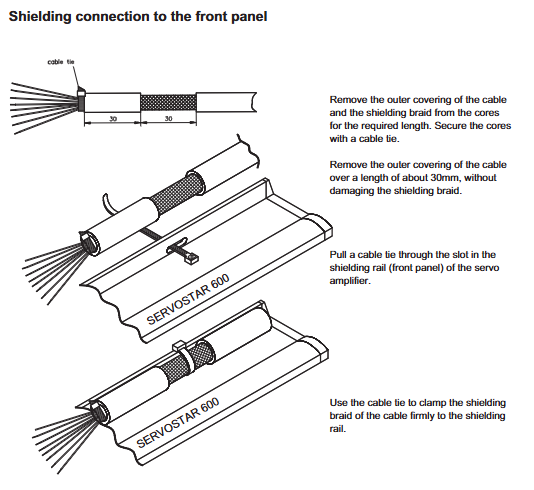

Simulation module: The signal ground and power ground are wired separately, and the analog signal cable adopts twisted pair shielded wire (single end grounding of the shielding layer) to avoid parallel connection with the power cable (spacing ≥ 200mm).

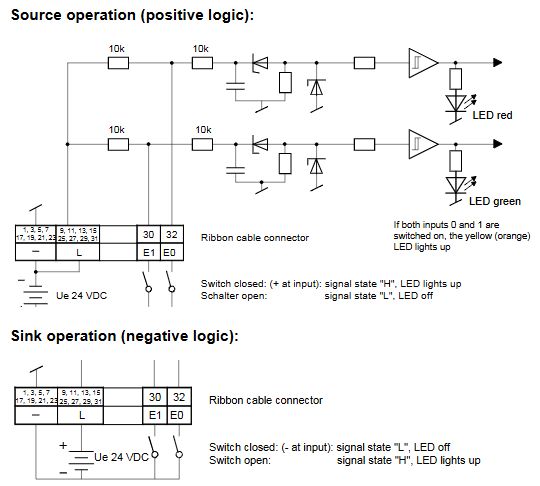

Typical wiring example

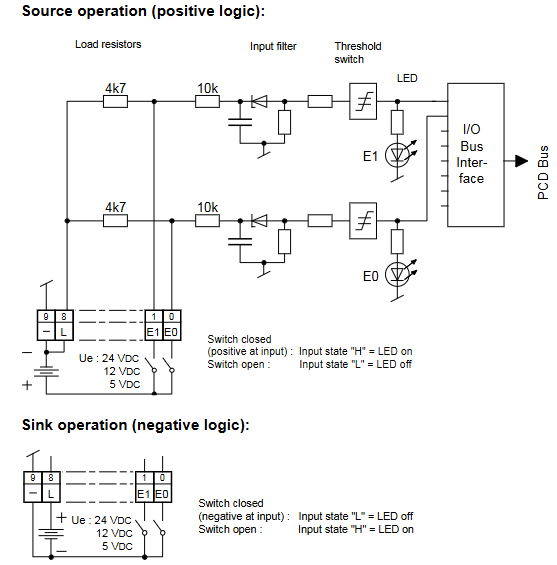

Digital input (source wiring): PCD2.E110 module E0-E7 is connected to the sensor signal,+24V is connected to the positive pole of the external power supply, and the negative pole of the sensor is connected to the module GND. The LED lights up to indicate that the input is valid;

Analog output (current type): PCD3.W410 module A0 connected to actuator (such as valve positioner), external 24V DC power supply positive pole connected to actuator, negative pole connected to module A0 terminal, select 4-20mA signal range through jumper;

Isolation module: The PCD2.E610 module needs to be separately connected to a 24V isolation power supply, and the signal end should be completely isolated from the PLC system ground to avoid common ground interference.

Function configuration and programming support

(1) Hardware configuration

Address setting

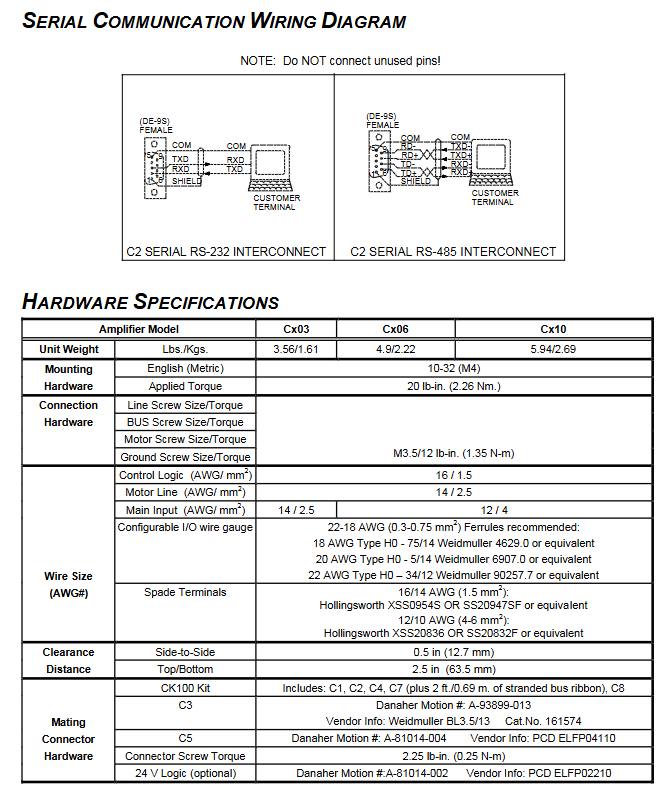

Digital module: Set the CANopen station address (1-99) and baud rate (10-1000kbit/s) through the DIP switch on the front-end of the module. After setting, restart the 24V power supply to take effect;

Expansion card configuration: Multifunctional modules such as PCD2.G410 need to be plugged into a communication expansion card (such as a PROFIBUS card) through Slot 1/2, and the module will automatically recognize it after power on. If it is not recognized, the locking status of the card buckle needs to be checked.

Signal filtering

Digital input: Select the filtering time through the internal jumper of the module (such as PCD2.E111 supporting 0.2ms/8ms switching), and select a short filtering time for high-frequency signals (such as encoders);

Analog input: PCD3.W380 supports software configuration of digital filtering (50/60Hz notch filtering) to suppress power grid interference, with a filtering time constant of 2.4ms.

(2) Software Configuration (PG5 Environment)

tool support

Saia PG5 software (version ≥ 2.3) is required to configure module parameters through the “Device Configurator”:

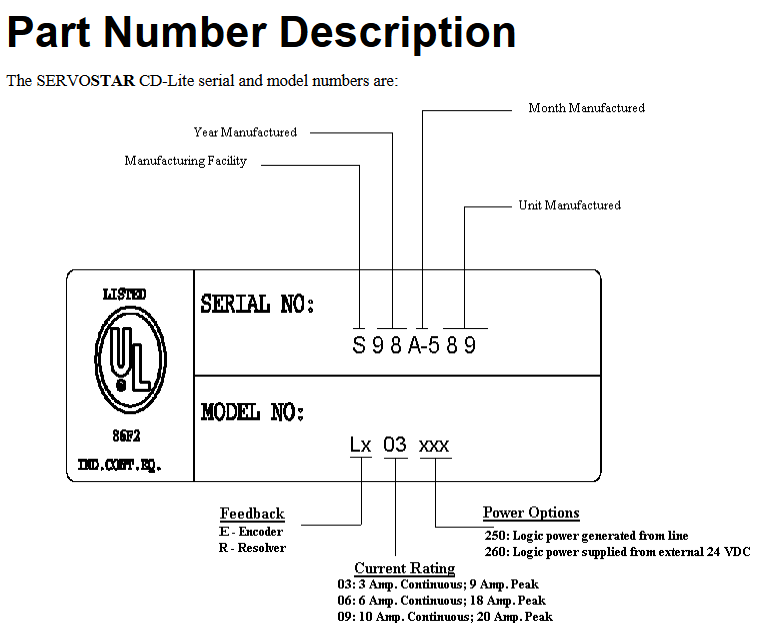

Motor configuration: Select the motor model (such as AKM series servo motor), automatically load rated current, inductance and other parameters, and execute “Motor Probe” to optimize the current loop gain;

Safety configuration: The STO function needs to be associated with a safety controller and set a periodic testing interval (≤ 8 hours, meeting SIL CL3 requirements);

Linearization of analog signals: The PCD2-W745 thermocouple module requires the selection of thermocouple type (J/K type), and the software automatically compensates for the cold junction temperature (compensation accuracy ± 0.2 ℃).

Programming Example

Counting function: PCD2.H100 reads the counting value through the IL command “RD-DIGIAL-IO-0TO15”, and sets “WR-DIGIAL-OUTPUT0TO15” to trigger the counter reset;

Servo control: PCD2.H310 sets the target position through the FB function block “MC_SoveAbsolute”, and the parameter “Position” is filled in with the number of pulses (to match the electronic gear ratio).

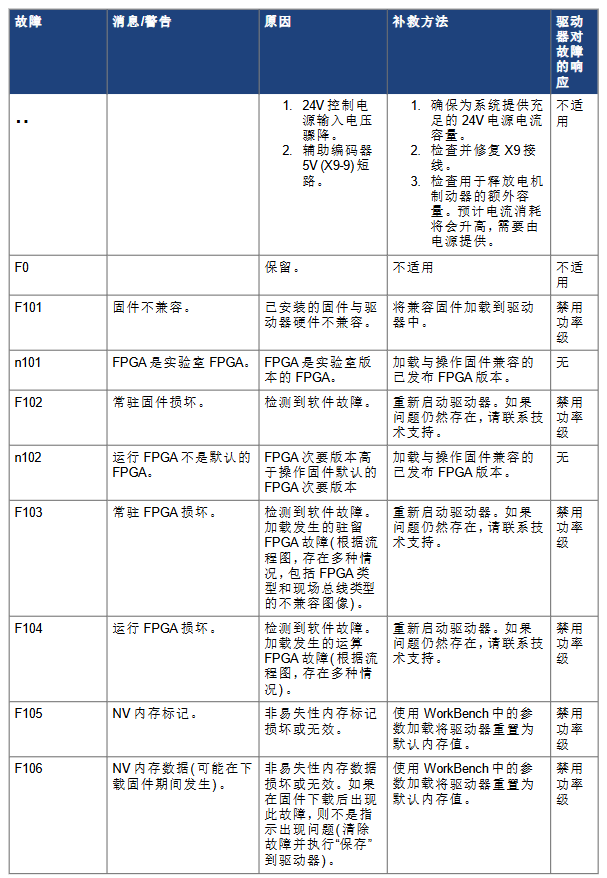

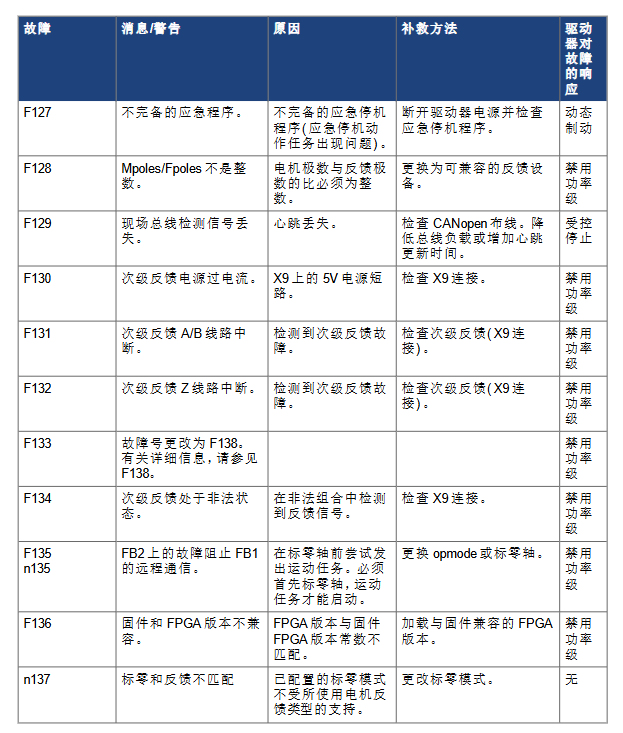

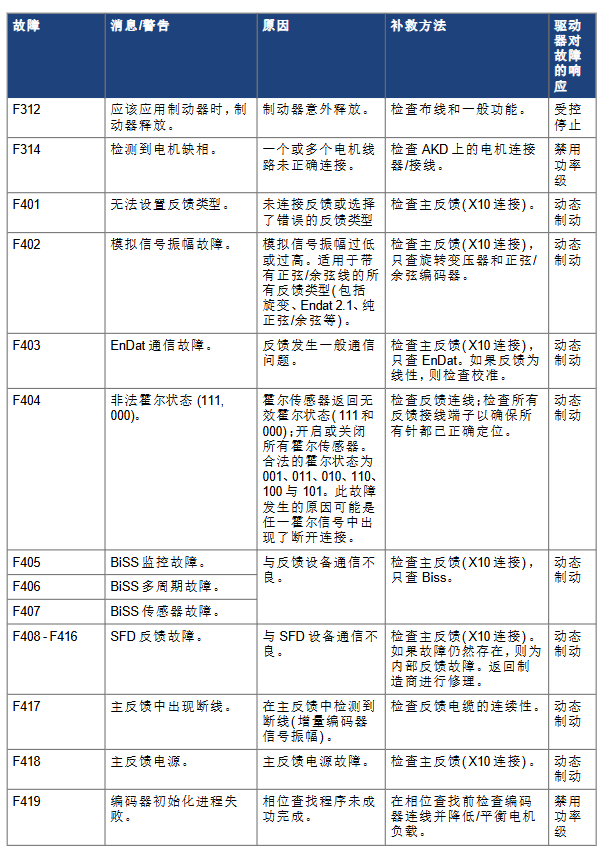

Troubleshooting and Maintenance

(1) Common faults and solutions

Troubleshooting steps for possible causes of fault phenomena

No response to digital input (LED not lit) 1. Power supply not working; 2. Loose wiring; 3. Input signal exceeds the range. 1. Measure the 24V voltage at the X4A terminal of the measurement module; 2. Re tighten the terminal screws (torque 0.8Nm); 3. Check the sensor output (e.g. NPN sensor needs to output a low level)

Simulated output deviation exceeds tolerance 1. Calibration parameters are lost; 2. Load impedance mismatch; 3. Signal distortion caused by interference. 1. Perform “Analog Calibration” through PG5 to recalibrate; 2. Confirm load resistance: voltage output ≥ 3k Ω, current output ≤ 500 Ω; 3. Add shielding layer grounding (single ended grounding)

Relay output contact adhesion: 1. Load current exceeds the set value; 2. Contactless protective components; 3. Frequent switching: 1. Measure the load current (such as A200 maximum 2A/channel); 2. Inductive load connected in parallel with 1N4007 freewheeling diode; 3. Reduce switching frequency (recommended ≤ 10 times/minute)

The frequency of the counting module is abnormal. 1. The encoder cable is too long; 2. Signal interference; 3. Improper setting of filtering time: 1. Cable length ≤ 10m (signal repeater is required for over distance); 2. Use twisted pair shielded wires (with the shielding layer grounded); 3. Set the filtering time to 1/5 of the signal period (e.g. 10 μ s for a 20kHz signal)

(2) Regular maintenance project

Standard requirements for maintenance project cycle operation content

Terminal inspection every quarter: 1. Tighten screw terminals (torque 0.7-0.8Nm); 2. Clean the terminal dust and ensure that the terminal is free from oxidation and looseness, with a contact resistance of ≤ 10m Ω

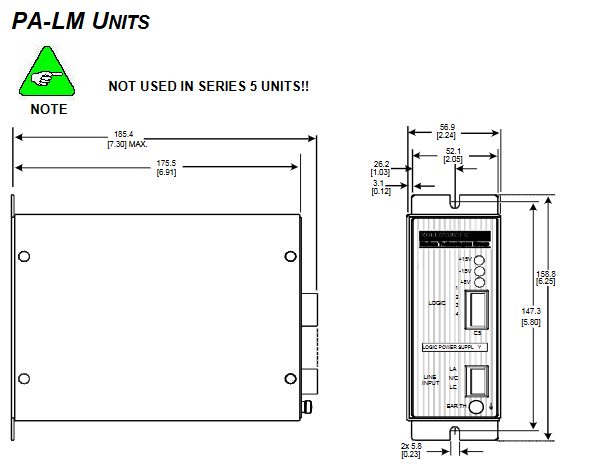

Module temperature monitoring: 1. Measure the temperature of the heat sink every month; 2. Check the fan speed (e.g. PCD2.H32x fan ≥ 2500rpm), the temperature of the heat sink is ≤ 75 ℃, and the fan has no abnormal noise

Calibration verification every six months: 1. Analog input: Input standard signal (such as 5V/10mA), read module values; 2. Analog output: Set 50% output, measure actual value deviation ≤ ± 0.5% (if exceeded, recalibration is required)

Monthly safety function testing: 1. Trigger the STO function and check if the motor torque is cut off; 2. After testing the safety relay contacts and activating STO, the motor has no torque, and the contact response is ≤ 10ms

Product lifecycle and spare parts management

Product status classification

The manual specifies the status of modules “Active”, “Outphased”, and “Repair phase”:

The maintenance period for discontinued modules (such as PCD2.G400/G410) is until December 31, 2018, and there will be no spare parts supply thereafter;

Alternative solutions: Replace PCD2.W100 with PCD2.W380, and PCD2.H222 with PCD3.H222.

Recommended spare parts list

It is recommended to reserve 1-2 sets of key spare parts, with the following matching models:

Module type/common model/spare part model

Digital input module/PCD3.E110/PCD3.E111 (compatible and responsive)

Analog output module/PCD2.W410/PCD3.W410 (terminal upgrade)

Relay module/PCD2.A200/PCD3.A200 (same function, higher anti-interference)

Counting module/PCD2.H100/PCD3.H110 (maximum frequency increased to 100kHz)