SIEMENS SIMATIC S5 S5-115U Programmable Controller

SIMATIC S5-115U is a programmable controller suitable for the mid to low end performance range. It adopts a modular design, with core components including power module, CPU (941/942/943/944 models), I/O module, etc. It supports both centralized and distributed configurations, and can expand up to 3 expansion units. In terms of communication, it is compatible with various systems such as SINEC L1. Programming relies on STEP 5 language and has functions such as interrupt handling and analog processing. It is suitable for multiple industries such as automotive, chemical, and food. Installation needs to follow mechanical fixation, standardized wiring, and electromagnetic compatibility requirements. Startup and testing need to complete steps such as overall reset, program transmission, parameter setting, and fault diagnosis.

Core hardware components

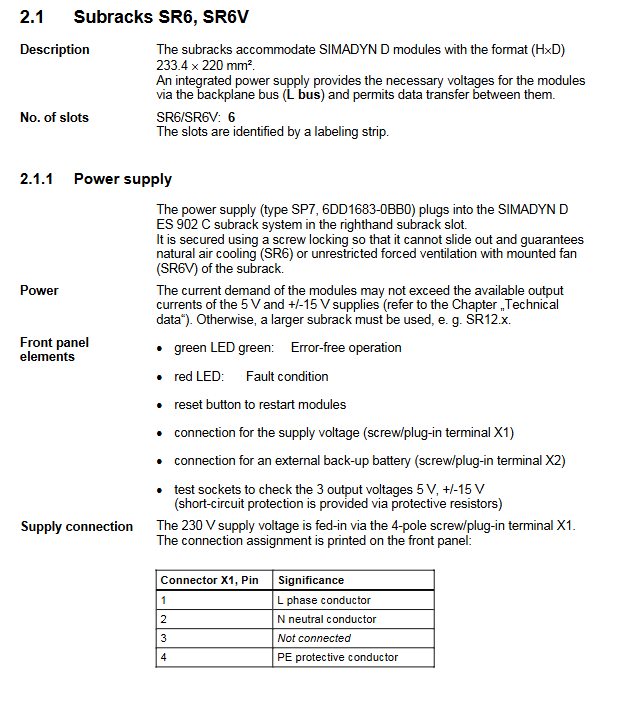

2.1 Power module (PS 951)

Input voltage: 120V AC, 230V AC, or 24V DC

Output current: 3A, 7A, 15A (7A and below do not require a fan)

Backup function: Lithium battery backup program memory and retention flag/timer/counter, battery life of about 2 years

Key features: Equipped with battery failure LED indicator, reset switch, voltage selection switch

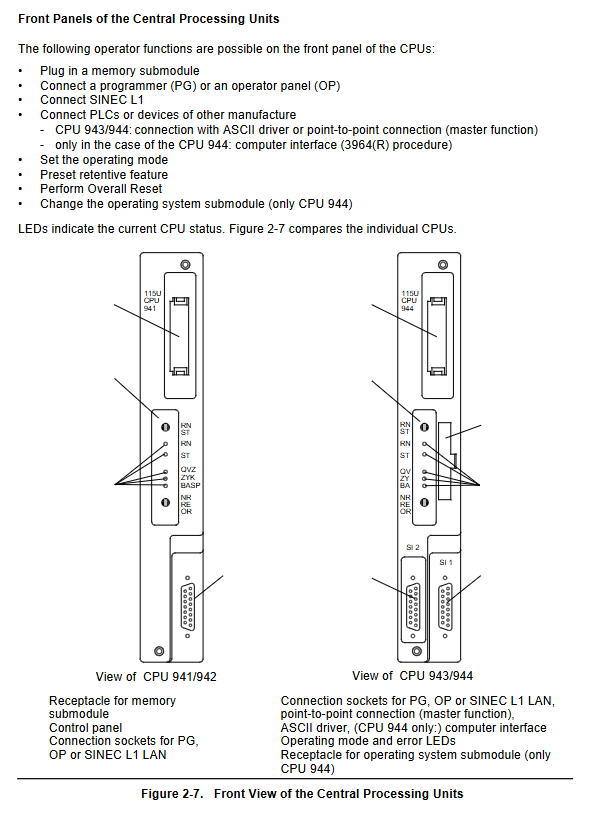

2.2 CPU module

CPU model, memory capacity, execution time (in thousands of instructions), core features

CPU 941 internal 2Kbytes, maximum 18Kbytes, approximately 10ms basic type, supports PID control

CPU 942 internal 10Kbytes, maximum 42Kbytes, approximately 10ms enhanced, supports PID control

CPU 943 internal 48Kbytes approximately 5ms dual serial ports, including real-time clock and ASCII driver

CPU 944 internal 96Kbytes, approximately 1.5ms dual serial port, supports 3964/3964R protocol, PID control

Common features: Supports 1024 flag bits, 128 timers/counters, time range 0.01-9990s, counting range 0-999

2.3 I/O modules

Digital module: adapted to machine voltage/current levels, supports screw or crimping connections

Simulation module: handles closed-loop control tasks, up to 4 measurement ranges per module, supports range card replacement

Intelligent I/O module: independent processor, parallel processing time critical tasks (counting, positioning, etc.)

2.4 Communication components

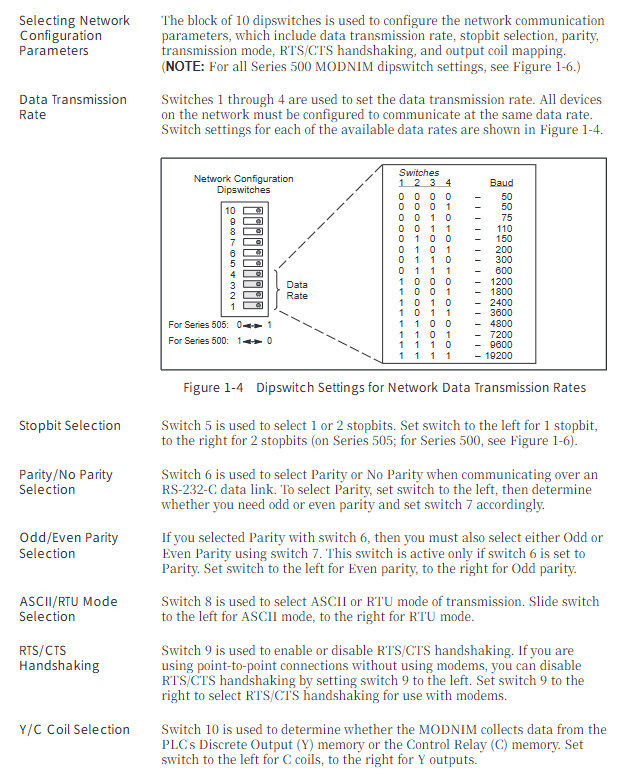

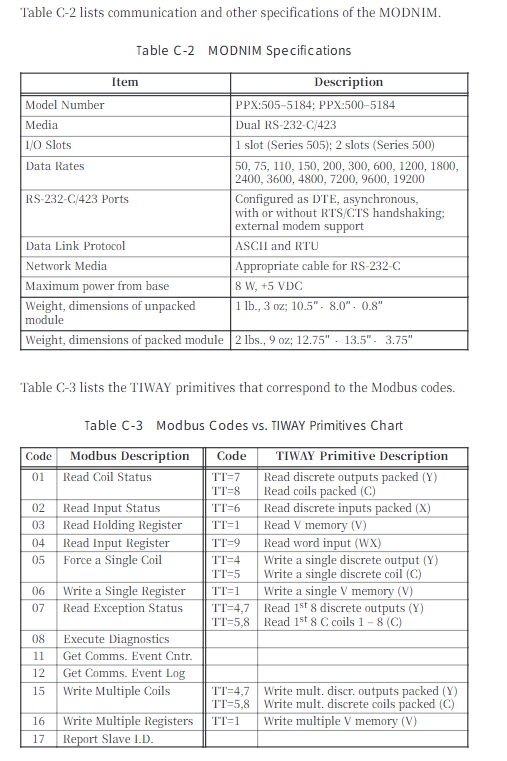

Communication system: Supports SINEC L1 LAN PROFIBUS、 Industrial Ethernet, point-to-point connection

Communication Processor (CP): divided into LAN type and link/signal/log type, adapted for human-machine and machine machine communication

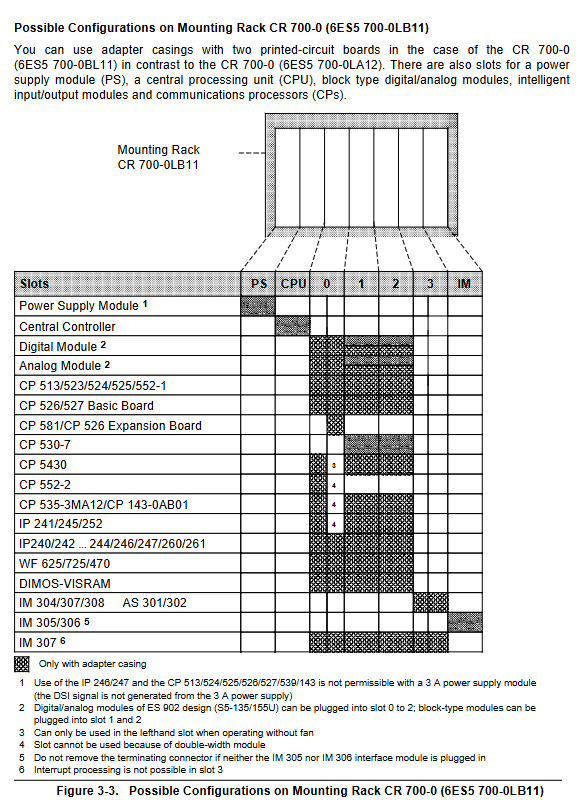

System configuration

3.1 Centralized Configuration

Structure: 1 central controller (CC)+up to 3 expansion units (EU)

Interface modules: IM 305 (supporting 1 EU, cable ≤ 1.5m), IM 306 (supporting 3 EU, cable ≤ 2.5m)

Power supply: EU takes power from CC through interface module, with a maximum power supply current of 2A (IM 306)

3.2 Distributed Configuration

Maximum distance: Depending on the interface module, it can reach up to 3000m

Interface modules: AS 301/302, IM 304/314, etc., supporting multiple EU extensions

Advantages: Reduce sensor/actuator wiring costs and install closer to the site

Programming and Functionality

4.1 Programming Fundamentals

Programming language: STEP 5, supports 4 representation methods, structured/linear programming

Program block types: Program block (PB), Function block (FB), Sequential block (SB), Data block (DB), Organization block (OB)

Execution method: Loop execution (OB1), interrupt driven, time controlled

4.2 Core Functions

Interrupt handling: Supports process interrupts, time interrupts, and response time can be calculated

Analog processing: compatible with multiple sensors, supports wire breakage detection and sampling, including FB250/251 matching blocks

PID control: up to 8 control loops, sampling time ≥ 100ms

Real time clock: Built in CPU 943/944, supports time related program execution

Installation and Startup

5.1 Installation Requirements

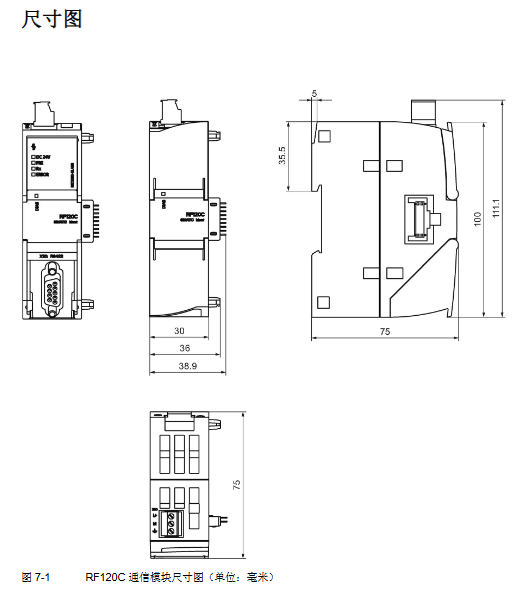

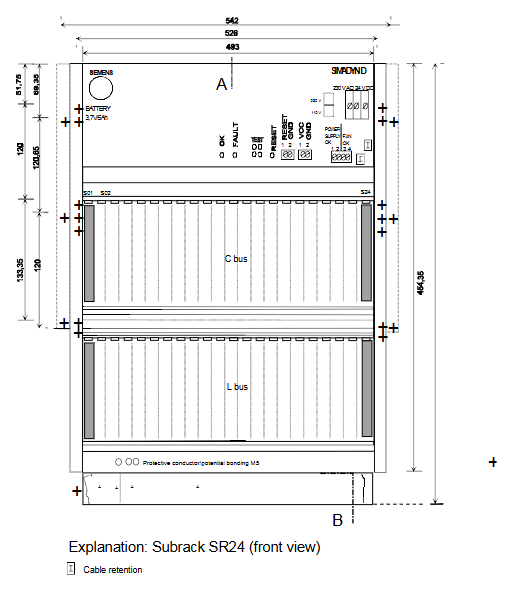

Mechanical installation: The module is fixed on the mounting bracket (CR/ER series), allowing for a 15 ° tilt installation. High power modules require a fan

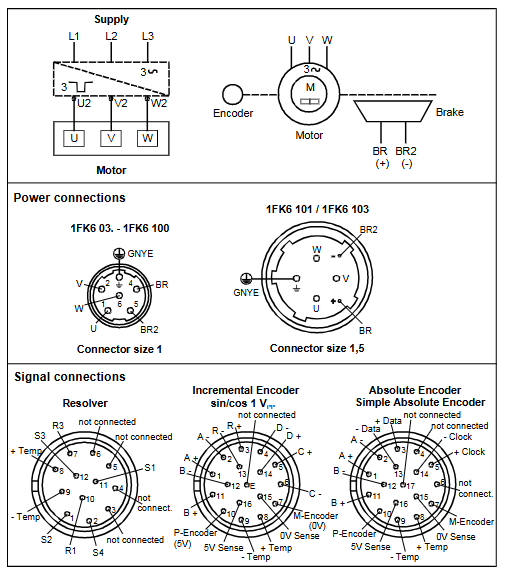

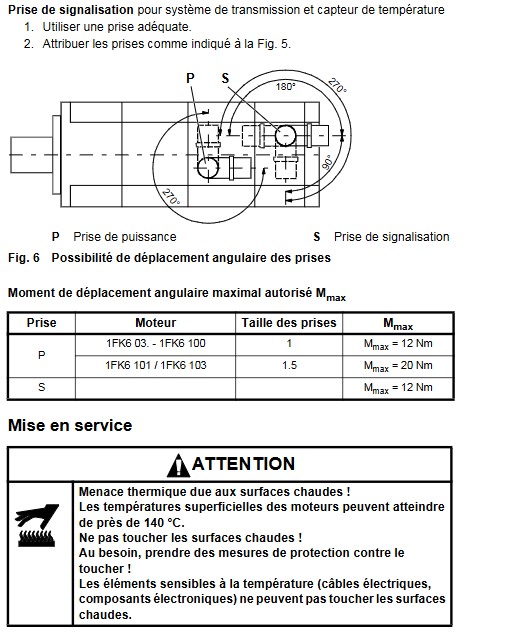

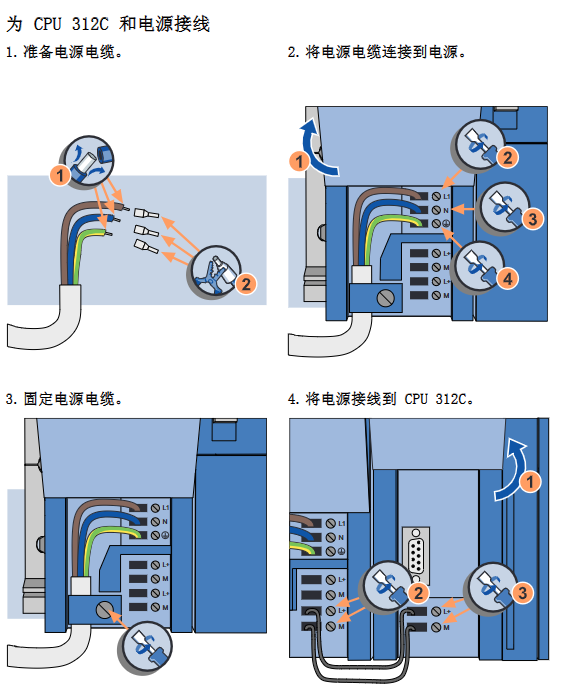

Wiring specifications: Distinguish between control circuits (5V/5.2V/24V) and load circuits, with different wiring for floating/non floating modules

Electromagnetic compatibility: Cable grouping and wiring, shielded cable double ended grounding, potential bonding conductor cross-section ≥ 16mm ² (≤ 200m)

5.2 Startup steps

Overall reset: Clear program memory, data, and error IDs, restore system data to default values

Program transfer: Directly transferred through memory submodules or programmers, automatically loaded into internal RAM by CPU 943/944

Parameter settings: Determine timer/counter/flag retention, set scan monitoring time (default 500ms, maximum 2.55s)

Program testing: Use functions such as STATUS/VAR, FORCE, etc. to check I/O signals and program logic

Fault diagnosis

Diagnostic tools: ISTACK (Interrupt Stack) analysis, LED indicator lights, BSTACK (Block Stack) program tracking

Common faults: battery failure (BAU signal), scan time timeout (ZYK), I/O not ready (PEU), memory error

Solution: Replace the faulty module, retransmit the program, check the wiring and terminal resistance