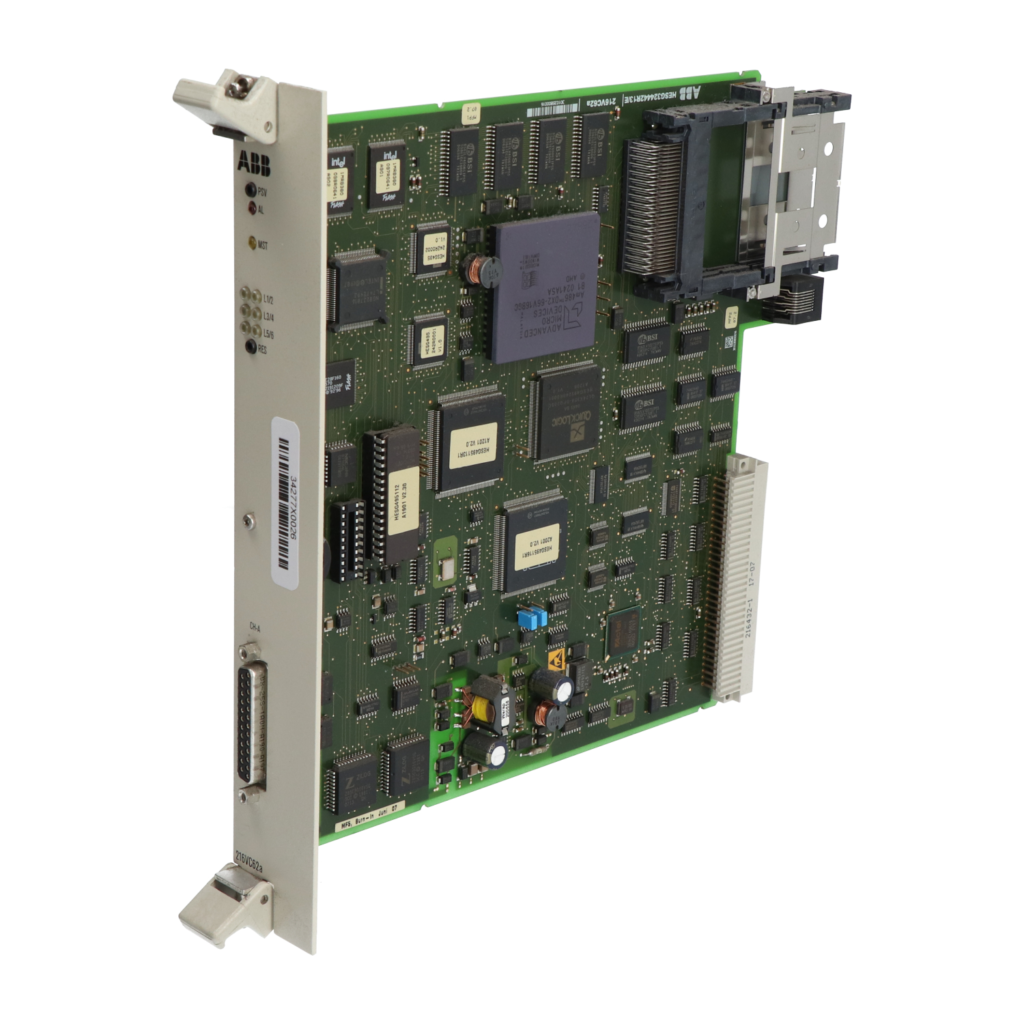

ABB UNS2980c-ZV4 digital I/O module

ABB UNS2980c-ZV4 is an advanced programmable logic controller (PLC) module designed for industrial automation applications. In the field of industrial automation, various devices and systems require reliable and efficient digital I/O modules to achieve signal acquisition and output in order to meet complex and changing control requirements. This module is an ideal choice for manufacturing and process control systems due to its outstanding performance, rich functionality, and high adaptability.

Key parameters of the product

Size specifications: Its external dimensions are 480 × 82 × 180mm. This size design ensures a reasonable layout of internal components, fully utilizes performance, and achieves efficient use of space as much as possible. Whether installed in compact control cabinets or in automated production line scenarios that require high equipment integration, it can be easily adapted without occupying too much valuable space.

input/output characteristic

Digital Input/Output Points: This module supports up to 512 digital input and output points, making it easy to handle complex signal acquisition and control tasks in large-scale automation projects. Whether it is digital signal input from numerous sensors, limit switches, buttons and other devices on site, or control signal output from a large number of actuators, relays and other devices, it can be accurately processed to ensure the stable operation of the entire automation system.

Input voltage: The input voltage is 24V DC, which has wide applicability in common industrial DC power supply systems. It can ensure the stability of signal transmission and match the output signal voltage of most industrial field devices, reducing the risk of equipment failure caused by voltage incompatibility.

Output capability: The output voltage is 24V DC, and the maximum output current is 10A. With strong output driving capability, it can directly drive load devices such as small contactors and solenoid valves that require certain driving current, reducing intermediate relays and other conversion links, simplifying system wiring, and improving system reliability and response speed.

Adaptability to work environment

Temperature range: The working temperature range is -20 ° C to+60 ° C, and some data shows that it can withstand extreme temperatures from -40 ° C to 70 ° C. This means that the module can maintain a stable working state under various harsh temperature conditions such as high temperature industrial furnaces, hot outdoor environments, cold storage, high-altitude and low-temperature areas, and continuously provide reliable digital I/O functions for automation systems.

Other environmental tolerance: The module has good dust, moisture, and electromagnetic interference resistance capabilities. It adopts a sealed shell design and electromagnetic shielding technology, effectively blocking dust and moisture from entering the internal circuit. At the same time, it can resist the interference of complex electromagnetic environments around it, ensuring normal operation in high electromagnetic interference industrial environments such as steel smelting and chemical production.

Communication capability: Supports multiple communication protocols such as Modbus, Profibus, Ethernet/IP, which enables seamless communication and connection with different brands and types of control systems and smart devices. Both traditional industrial automation networks and emerging industrial Ethernet architectures can be easily integrated to achieve rapid data exchange and sharing, laying a solid foundation for building intelligent and integrated industrial automation systems.

Memory configuration: It has 1MB of flash memory and 256KB of random access memory (RAM). Sufficient flash memory is used to store important data such as control programs and system configuration parameters written by users, ensuring that data is not lost after the device is powered off; A moderate amount of RAM provides temporary space for data processing and variable storage during program execution, ensuring that the program can run efficiently and stably.

Power consumption: The maximum power consumption is 10W, which meets the requirements of powerful functions while maintaining a low energy consumption level, in line with the pursuit of energy conservation and environmental protection in today’s industrial field, and helps to reduce the operating costs and energy consumption of enterprises.

Performance advantages

High flexibility and scalability: The module supports a wide range of digital input and output points, and can be flexibly expanded or combined according to actual project requirements. In the upgrade and renovation project of the automated production line, if the original system has insufficient digital I/O points, the UNS2980c-ZV4 module can be easily added without the need for large-scale redesign and wiring of the entire control system, greatly saving time and cost, and easily adapting to constantly changing production processes and control requirements.

Excellent reliability: In terms of hardware design, high-quality electronic components are selected and rigorously screened and aged to ensure the stability of each component during long-term operation; At the software level, it has a comprehensive self diagnostic function and fault tolerance mechanism, which can monitor its own working status in real time. Once an abnormality is detected, corresponding measures are taken immediately for processing, such as automatic switching of backup channels, issuing fault alarm signals, etc., to ensure the uninterrupted operation of the system. In continuous production chemical enterprises, even if a temporary failure occurs in one input channel, the module can automatically switch to the backup channel to ensure that the production process is not affected and avoid huge economic losses caused by equipment shutdown.

Easy to integrate and use: With support for multiple mainstream communication protocols, it can quickly integrate with existing industrial automation systems. During the project implementation process, engineers do not need to spend a lot of time on complex communication interface development and debugging work, which can significantly shorten the project implementation cycle. At the same time, its operating interface is simple and clear, and the programming method complies with the IEC 61131-3 standard, making it easy for engineers to understand and master, reducing the threshold for use. Even relatively inexperienced technicians can quickly get started, configure modules, and write programs.