ABB S503X Circuit Breaker

The following is a comprehensive introduction to ABB S503X circuit breaker, combined with the S500 series characteristics and industrial application scenarios in the document:

Product positioning and overview

S503X belongs to ABB S500 series miniature circuit breakers (MCBs), designed for three poles (3P), mainly used for overload and short circuit protection in industrial and commercial circuits, especially suitable for three-phase alternating current (AC) or direct current (DC) systems. Its design is compact, supports DIN rail installation, complies with standards such as UL 1077 and IEC 60947, and is suitable for scenarios such as motor control, power distribution systems, and automation equipment.

Core technical parameters

Electrical parameters

Voltage range:

AC model (such as S503-K): 600V AC (UL)/690V AC (IEC).

DC models (such as S503UC-K/B): 250V DC (single pole)/750V DC (four pole).

Current range: 0.1-45 A (K-curve, inductive load) or 6-63 A (B-curve, DC load).

Breaking capacity: up to 30 kA (UL/CSA/IEC standards).

Physical specifications

Number of poles: 3 poles (3P), with a width of approximately 52.5mm (single pole 17.5mm x 3).

Installation method: 35mm DIN rail installation, supporting vertical or horizontal installation.

Terminal type: Anti electric shock design, supporting wire cross-sectional area of 1.5-10mm ² (M4 screw, torque 1.7N · m).

Release characteristics

K-curve: Suitable for inductive loads such as motors and transformers, allowing for high surge currents during startup (such as 8-12 times the rated current).

B curve (DC model): suitable for DC circuits, more sensitive to overload and short circuit reactions.

Function and application scenarios

Core functions

Thermal magnetic trip protection:

Thermal trip: For overload current, the trip is triggered by heating and bending of a bimetallic strip.

Magnetic trip: For short-circuit current, it trips instantly through an electromagnetic mechanism.

Quick disconnection: The disconnection time is 2.3-2.5ms, reducing the duration of faults and lowering the risk of equipment damage.

Status feedback: Supports auxiliary contacts (optional) and outputs circuit breaker on/off status signals.

Typical applications

Industrial automation: three-phase motor control (such as conveyor belts, fans), PLC system power supply protection.

Energy and Infrastructure: DC Circuit Protection for Photovoltaic Inverters and Energy Storage Systems (DC Models).

Commercial buildings: Overload protection for three-phase circuits in distribution boxes and lighting systems.

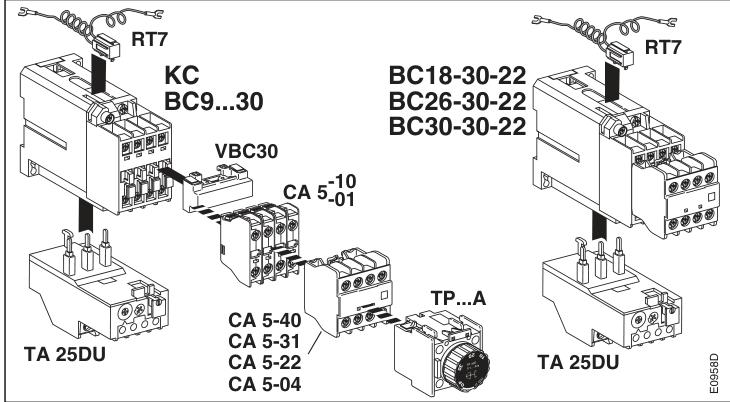

Motor starter matching: Combined with contactors and soft starters, it forms a complete motor control circuit.

Model and Selection Reference

Model, prefix, type, number of poles, current range, typical applications

S503-K AC circuit breaker 3P 0.1-45 A three-phase AC motor, transformer

S503UC-K DC Circuit Breaker 3P 0.1-45 A DC Motor and Battery System

S503UC-B DC circuit breaker 3P 6-63A high current DC load (such as welding machine)

Example:

S503-K4.2: Three pole AC circuit breaker, current 2.8-4.2 A, suitable for small three-phase motor protection

S503UC-K45: Three pole DC circuit breaker, current 38-45 A, suitable for industrial DC distribution systems.