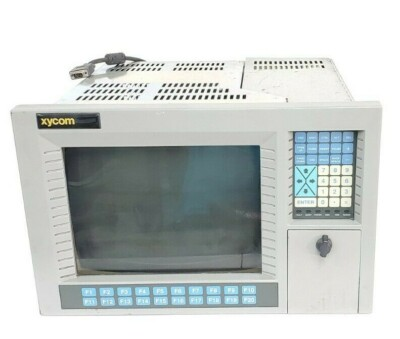

XYCOM Automatic 9987 Operating Interface PN.9987-3338-2100

The 9987 PC/AT™ Flat-panel Industrial Computer (also known as the Portrait PC) com bines a PC/AT computer with a flat-panel display to offer a powerful, compact package for the factory floor and other harsh environments.

The 9987 features an open architec ture to meet a wide variety of applications where both a powerful PC and a durable in dustrial enclosure are required.

The system integrates a computer card cage, mass stor age, display, keypads, and power supply in a truly industrial form factor.

The 9987 system includes a four-slot, full-length, passive ISA backplane, a VGA flat panel display, hard and floppy disk drive facilities, and data entry/function keypads.

The front panel is sealed to NEMA 4/4X/12 standards, and the flat-panel display is protected by an impact-resistant shield.

The open-architecture design accepts IBM PC/AT compatible cards and keyboards.

The processor board combines the functions of a IBM PC/AT-compatible computer on a single, industrially-hardened circuit board. Refer to the Xycom CPU manual for more in formation on processor and hardware features.

The system’s modular design allows easy access to boards, switches, power supply, and disk drives.

You can easily remove the drawer by detaching six ACCESS fasteners.

Standard Features

The 9987 offers the following standard features:

• High-performance, single-board 486 and Pentium® processors

• 5.62-inch mounting depth

• Four-slot, full-length, passive ISA backplane

• 10.4-inch 256-color CCFT TFT LCD flat-panel display (640×480)

• 32 data entry and 10 function keys

• 3.5-inch 1.44 Mbyte floppy drive

• MS-DOS®

• Slide-out computer module (to access disk, backplane, and power supply)

• 110-watt power supply

• IBM PC/AT compatibility

• Front or rear access floppy disk

• External printer port

• External COM1 and COM2 ports (RS-232)

• Front panel sealed to meet NEMA 4/4X/12 specifications when panel mounted

Optional Features

The following optional items are also available with the 9987:

• A variety of high-capacity IDE hard drives and Solid State (Flash) drives

• RADAR card with isolated RS-232C/RS-485 serial ports

• External full-stroke keyboard

• Durapoint sealed front-panel mouse

• Various sealed rack- or panel-mount keyboards

• Preloaded Windows® 95 or Windows NT operating systems

• Hazardous location configurations

Unpacking the System

When you remove the 9987 from its box, verify that you have the parts listed below.

Save the box and inner wrapping in case you need to reship the unit.

• 9987 unit

• Documentation kit, which includes

Power cable

PKIM utility disk

Diagnostic software disk

20 hex nuts (6 spares)

9987 user manual

CPU manual

VGA utility disk

• Binder

• Business reply card

Quick Start-up

Warning

Turn off the power to the unit and unplug the power cord before making any adjust ments to the inside or outside of the computer.

Perform the following steps to prepare the system for use.

1. Attach optional keyboards/mouse.

• Connect an external keyboard to the keyboard connector behind the access door on the front panel or to the connector on the power panel.

• A serial mouse can be connected to either COM1 or COM2. When a mouse is used, the COM LED on the data entry keypad lights up.

2. Attach other optional equipment following the instructions in Chapter 3.

3. Attach the power cord from the power receptacle to a properly grounded 90-250 VAC, 50-60 Hz outlet.

4. Turn on the power to the unit. The system will boot up at the C: prompt.

5. Install application software via drive A: located behind the access door on the front panel

Quadtel BIOS

If the CPU board has a Quadtel BIOS, press CTRL+ALT+S simultaneously after the POST RAM test has completed to access the Setup Menu.

Make changes by following directions on the screen.

Press F10 to save the Setup, and ESC to exit. Refer to your CPU manual for more information on the Setup Menu.

Preparing for the Tests

To test your system, you need the following equipment:

• Xycom System Test Disk (bootable 3.5-inch, DS/DD disk), Xycom part number

99290-001

• IBM PC/AT-compatible keyboard (Xycom part number 91971-001 or equivalent)

• Centronics-compatible printer cable

• Parallel printer (Centronics-style interface)

• Two serial loopback test connectors (refer to Figure 2-1 for pinouts)

• Formatted scratch disk (3.5-inch, DS/HD)

Perform the steps below before starting the system tests:

1. Place the CPU board jumpers and switches to the factory-set positions. Refer to your

CPU manual for these settings.

2. Plug the female end of the AC power cable into the side of the unit and the male end

into a properly grounded outlet.

3. Connect the serial loopback connector(s) and the printer cable to the appropriate

connectors and connect a PC/AT keyboard to a keyboard connector. Figure Chapter

2 -1 illustrates the wiring necessary for the loopback connection.

Removing the Slide-Out Module

1. Remove the six ACCESS fasteners that attach the slide-out computer module to

the 9987 back panel. (A ¼-inch nut driver is needed to remove the 8/32 size fas teners.)

2. If the unit is not panel mounted, place it face down. Hold the front part down

(located behind keypad) while pulling off the back panel to break the intercon nect connection.

3. Grasp the handles that protrude from the back panel on the left and right sides, above the I/O inserts.

4. Pull straight back. The module should slide out easily.

9000-RAD Card

You can install the 9000-RAD card if you have an open slot.

Before installing the card (Solid State Disk) into the 9987, jumpers and switches must be set for your par ticular configuration.

After the 9000-RAD is properly configured, it can be installed into the 9987 card

cage as follows:

1. Unplug the 9987 from the AC wall outlet.

2. Remove the 9987 slide-out computer module (refer to the Removing the Slide

Out Module section earlier in this chapter). Set the six ACCESS fasteners aside for later use.

3. Verify jumper and switch settings. Refer to the 9000-RAD manual for the cor rect settings.

4. If present, remove the blank ORB from the slot that the 9000-RAD card will oc cupy. Save the screw.

5. Place the 9000-RAD card into the slots in the backplane. Push down on the card evenly, until it firmly seats into the card edge connectors.

FloNet Interface Board

You can also install a IPN200 FloNet interface board in your system.

The FloNet board has two modes of operation:

Ethernet and FloNet. In Ethernet mode, the board provides a standard Ethernet network interface with user-configurable hardware in terrupts, I/O ports, and bootable ROM BIOS address location.

In FloNet mode, the FloNet board acts as the interface between a local host running FloPro software and an Ethernet LAN connected to at least one remote host platform running TCP/IP-compatible software.

The on-board firmware constantly polls the Ethernet network interface waiting for packets where are intended to communicate with FloPro.

The board will also process valid TCP/IP protocol packets.

When configured for FloPro mode, the FloNet board takes up to six eight-bit I/O ports, and 32 Kbytes of memory.

When configured as an Ethernet card, the FloNet board takes an additional 16 I/O addresses.

It may also take up an additional 32

Kbytes of memory space if configured to use a boot ROM.

Refer to the FloNet documentation for installation instructions