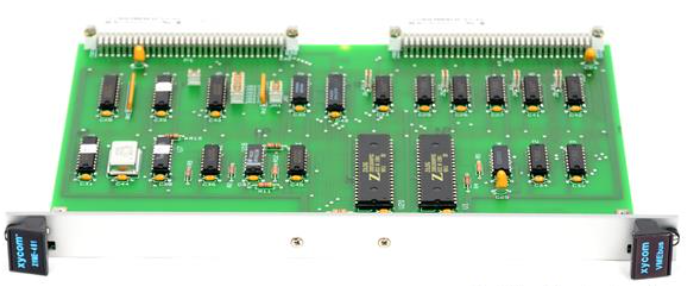

Xycom 144365-001 motherboard

Product Overview

The Xycom 144365-001 motherboard is a key circuit board product developed by XYCOM for industrial and professional applications. This motherboard is designed with full consideration of the strict requirements for stability, reliability, high-performance computing, and data processing in complex working environments. It can serve as a core component to provide a stable and efficient operating foundation for various industrial equipment, automation systems, and professional computing platforms, helping the system achieve precise control and smooth data exchange, ensuring the stable operation of the entire system.

Brand background

XYCOM, as a leader in the fields of industrial automation and embedded systems, has long held an important position in the market due to its profound technological accumulation and precise understanding of industry demands. The company has always been committed to providing cutting-edge control and computing solutions to global customers, with products covering a wide range of key industries such as industrial automation, process control, transportation, and energy management. With its advanced technology research and development capabilities, strict quality control system, and comprehensive customer service network, Xycom 144365-001 motherboard has won high recognition and trust from global users. It is a reflection of the brand’s strength and professional spirit.

Specification parameters

Processor adaptation: This motherboard can adapt to various high-performance processors. Although the specific processor models may vary due to application scenarios and customer customization needs, it can provide powerful computing power to the system as a whole, easily handle complex data processing tasks in industrial scenarios, ensure smooth system operation, and respond promptly.

Memory performance: The motherboard is equipped with high-performance memory slots, supporting multiple specifications of memory modules, and can flexibly expand memory capacity according to actual needs to meet the requirements of different applications for data storage and fast reading. The high-speed memory read and write speed ensures that the processor can quickly obtain the required data when executing tasks, improving the overall performance of the system.

Interface details:

Serial interface: It has multiple RS-232/RS-485 serial ports, which provide convenience for connecting various serial devices such as industrial sensors, smart meters, serial communication modules, etc., facilitating data transmission and instruction interaction between devices.

USB interface: Multiple USB 2.0 or higher version interfaces are set up, which can be used to connect external storage devices, keyboards, mice, printers and other general-purpose devices, greatly expanding the functional application range of the motherboard and improving the usability of the system.

Network interface: Integrated with 10/100/1000Mbps Ethernet interface, it ensures stable and high-speed network connection, meets the needs of rapid transmission of large amounts of data between devices and devices, as well as between devices and the cloud in industrial IoT environments, and realizes functions such as remote monitoring, data collection, and remote control.

Other interfaces: may also have parallel ports for connecting specific industrial equipment or high-speed data transmission; Video output ports, such as VGA, HDMI, etc., are convenient for connecting to displays, enabling visual display of system status and data; PS/2 interface, capable of connecting traditional keyboards and mice, ensuring convenient operation in various environments; Audio interface, used to achieve functions such as voice communication or audio prompts.

Size and Construction: In terms of size design, the motherboard fully considers the compactness of the internal space of industrial equipment, adopts reasonable external dimensions, and can adapt to the installation needs of various industrial chassis and equipment. Its shell and internal structure are made of sturdy and durable materials, with good anti vibration and anti impact performance, which can effectively resist common mechanical stresses in industrial environments, ensuring stable operation of the motherboard under harsh working conditions and reducing the risk of failure caused by physical damage.

Power requirements: The motherboard supports a wide range of power input, typically 9-30 Volt regulated DC input, which enables it to adapt to different industrial power environments. In addition, external AC power supplies can be flexibly selected according to actual application scenarios to meet diverse power supply needs and ensure that the equipment can operate continuously and stably under different power conditions.

Precautions

Installation environment requirements: The motherboard should be installed in a dry, well ventilated, and suitable temperature environment. Avoid using in environments with high temperatures (exceeding the specified working temperature range), high humidity (relative humidity exceeding the allowable range), or high dust, as these harsh environments may cause damage, short circuits, or performance degradation of electronic components on the motherboard, thereby affecting its normal operation and service life.

Key points for power connection: When connecting the power supply, it is necessary to ensure that the voltage range and specifications of the input power supply are completely matched with the requirements of the motherboard. Carefully check the positive and negative polarity of the power supply to avoid reverse connection, otherwise it may instantly burn sensitive components on the motherboard, causing irreversible damage. If using an external AC power supply, it is necessary to strictly select the appropriate model and connect it according to the correct wiring method to ensure the stability and safety of the power supply.

Interface Usage Specification: When connecting external devices to the motherboard interface, carefully confirm whether the type and specifications of the device interface are consistent with those of the motherboard interface to ensure a matching connection. It is strictly prohibited to forcefully plug or unplug interface devices to avoid damaging the physical structure of the interface, resulting in poor contact or data transmission failures. During the operation of the device, try to minimize frequent plugging and unplugging of interface devices, as this may cause momentary current surges or data transmission errors, affecting the normal operation of the device and even damaging the device and motherboard.

Attention to installation of expansion modules: If expansion modules such as PCI cards, PCI Express cards, etc. need to be installed, the device power must be turned off before operation to prevent the risk of electric shock and short circuit. During the installation process, it is necessary to strictly follow the instructions in the product manual, correctly align the slot position, smoothly insert the expansion module, and ensure that it is firmly fixed. If installed improperly, it may cause the system to not recognize the expansion module, resulting in compatibility issues, and even damaging the motherboard slot or the expansion module itself.

System maintenance suggestion: Regular comprehensive inspection and maintenance of devices installed with this motherboard are key to ensuring its long-term stable operation. Daily maintenance work includes cleaning the dust on the surface and inside of the equipment to prevent dust accumulation from affecting heat dissipation and electrical performance; Check if the interface connection is loose, and if there is any looseness, promptly re plug and fix it; Regularly update system software, install the latest operating system patches and application upgrade packages to improve system security and stability, and fix potential software vulnerabilities.