ALSTOM DFI-150-0003- Limelight Diagnostic Board

Product overview

ALSTOM DFI-150-0003 Limelight Diagnostic Board is a high-performance flame detector circuit board designed specifically for industrial environments. Its core task is to accurately detect flames during welding, cutting, and various combustion processes, and to undertake the responsibility of safety monitoring. With advanced technology and reliable performance, it has become a key component in ensuring stable equipment operation and improving production efficiency in many industrial production processes.

Brand background

ALSTOM, as a leading global supplier of energy and transportation solutions, has an outstanding reputation in the industry. Over the years, with profound technological accumulation and a spirit of continuous innovation, ALSTOM’s products have widely penetrated into multiple important fields such as power, railway, and industry. Its strict control over quality and precise insight into customer needs make every product synonymous with reliability and advancement. The DFI-150-0003 Limelight diagnostic board is a typical representative of this brand philosophy.

Specification parameters

Electrical parameters

Rated voltage: 220V, suitable for common industrial power supply standards.

Rated current: 15A, meeting the current requirements for stable operation of the equipment.

Frequency: 50/60Hz, compatible with power frequencies in different regions.

Input voltage range: Supports DC working voltage and has certain voltage adaptability.

Isolation voltage: up to 2500Vrms, effectively ensuring circuit safety and preventing electrical faults from interfering.

Overvoltage protection: ± 30V, capable of handling instantaneous voltage fluctuations and protecting internal circuit components.

Static current: ≤ 5mA, with extremely low energy consumption in standby and other static states.

Dynamic current: ≤ 25mA, stable current during operation to ensure efficient operation of the equipment.

Physical and environmental parameters

Protection level: Available in IP66 or IP20 ratings. IP66 rating can achieve dust, water, and strong water spray prevention, suitable for extremely harsh industrial environments; The IP20 rating provides basic dust protection and is suitable for places with relatively good environments.

Working temperature range: -20 ℃ to+70 ℃, can work stably in cold or high temperature industrial scenarios.

Size: Typically 172mm x 95mm x 142mm, the compact design makes it easy to install inside various devices.

Interface and signal parameters

Output signal type: equipped with multiple switch output and analog output interfaces, convenient for connecting with different types of control systems. Simultaneously supporting RS485 communication ports to achieve efficient data transmission and communication.

Interface type: Provides digital or analog interfaces, which can be flexibly customized according to actual application needs to meet diverse device connection requirements.

Signal type: Supports infrared, ultraviolet, ion current, visible light, and multi band flame signal input, greatly improving the accuracy and comprehensiveness of flame detection.

Response time: less than 1 second, able to quickly capture changes in flame state and provide timely feedback information.

Core functions

Flame detection: Utilizing advanced sensor technology to accurately identify multiple flame signals. Both weak welding flames and high-temperature combustion flames can be quickly and accurately detected, providing reliable basis for subsequent control and decision-making.

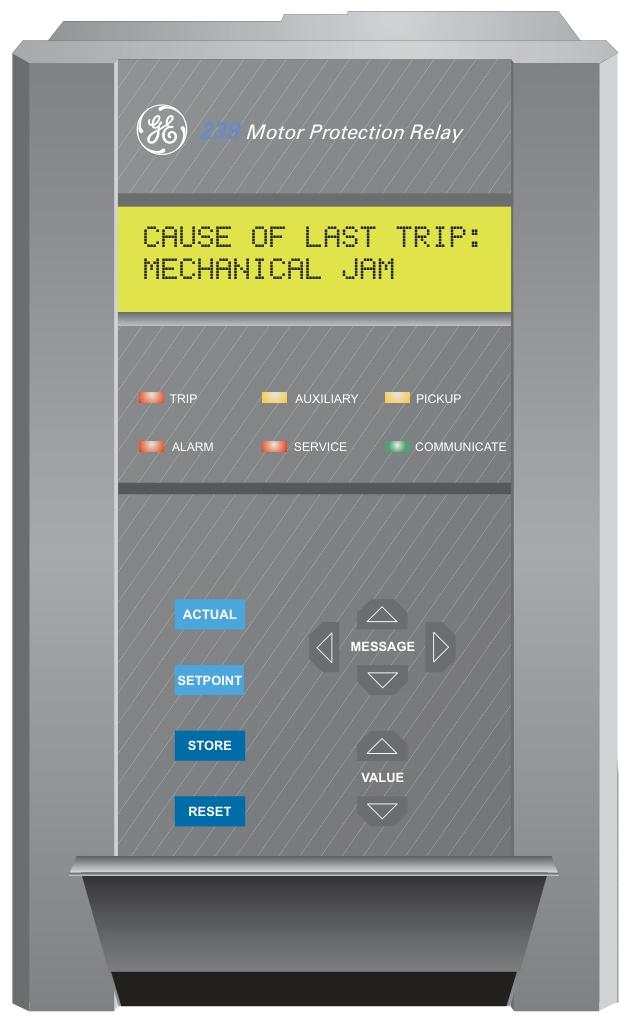

Fault diagnosis: Built in powerful self diagnostic program, constantly monitoring its own working status. Once internal circuit faults or signal abnormalities are detected, clear alarm signals should be immediately issued to help maintenance personnel quickly locate the fault point and shorten equipment downtime.

Process control: Real time feedback of detected flame status information to the control system in the form of digital or analog signals. The control system adjusts the operating parameters of the equipment accordingly, such as adjusting the fuel supply of the burner, controlling the power of the cutting equipment, etc., in order to achieve precise control of the industrial production process, improve product quality and production efficiency.

Digital display: Equipped with an intuitive digital display screen, it presents real-time key parameters of the flame, such as flame intensity, combustion stability, etc. Operators do not need complex instrument detection, and can quickly understand the flame status through the display screen, which facilitates equipment debugging, maintenance, and daily monitoring.

Working principle

The DFI-150-0003 Limelight diagnostic board receives signals such as infrared, ultraviolet, ion current, and visible light generated by flames through specific sensors. After being preliminarily amplified by a preamplifier, these signals are transmitted to the signal processing circuit. The signal processing circuit uses complex algorithms to analyze, filter, and extract features from signals, in order to distinguish between real flame signals and environmental interference signals. Once the flame signal is confirmed to be valid, the diagnostic board will generate corresponding control signals and status information based on preset rules and algorithms. On the one hand, this information is transmitted to the external control system through the output interface for device operation control; On the other hand, it is visually presented on a digital display screen, making it convenient for operators to monitor in real-time. At the same time, the self diagnostic module will continuously check the hardware and software operation status of the diagnostic board itself to ensure the reliability of the entire system.

Key advantages

High sensitivity and anti-interference: Advanced signal processing technology and high-sensitivity sensors are used to accurately detect extremely weak flame signals. At the same time, through multiple filtering and anti-interference algorithms, the impact of environmental noise, electromagnetic interference and other factors on the detection results is effectively reduced, greatly reducing the false alarm rate and ensuring the accuracy and reliability of the detection results.

Quick response and alarm: When detecting flame abnormalities or equipment failures, it can respond in a very short time (less than 1 second) and quickly emit clear and loud alarm signals. This feature has won valuable time for timely handling of potential hazards and avoiding accidents, effectively ensuring the safety of industrial production.

Industrial grade design: From hardware material selection to software algorithms, strict industrial standards are followed for design. The high protection level shell, wide temperature range adaptability, and stable and reliable circuit design enable it to operate stably for a long time in harsh industrial environments such as high temperature, humidity, dust, and strong electromagnetic interference, with excellent durability and reliability.

Self diagnostic function: The powerful self diagnostic function can monitor the working status of the diagnostic board in real time, including the integrity of hardware circuits, the operation of software programs, etc. Once abnormalities are detected, maintenance personnel are immediately notified through the alarm system, greatly improving the convenience and efficiency of equipment maintenance and reducing equipment failure rates.

Digital reading function: The intuitive digital display screen presents the flame state and equipment operating parameters in a clear and easy to understand manner, allowing operators to quickly read information without complex training. This not only facilitates the daily operation and maintenance of the equipment, but also improves work efficiency and reduces operational errors caused by human error.

Precautions

Installation environment: It should be installed in a dry, well ventilated environment without strong electromagnetic interference. Avoid installing in high temperature, humid or dusty places to prevent affecting equipment performance and service life. If used in an environment with explosion-proof requirements, it is necessary to ensure that the equipment installation complies with the corresponding explosion-proof standards.

Electrical connection: When making electrical connections, it is necessary to strictly follow the requirements of the product manual. Ensure that the wiring is secure and avoid loose connections that may cause poor contact or short circuit faults. At the same time, attention should be paid to the matching of input and output voltage and current to prevent equipment damage due to mismatched electrical parameters.

Regular maintenance: It is recommended to regularly inspect and maintain the equipment, including cleaning the casing, checking for loose wiring, and testing the sensitivity of sensors. Regular maintenance helps to promptly identify potential issues and ensure that the equipment is always in optimal working condition.

Software upgrade: Follow the official software upgrade information released by ALSTOM and update the device’s software in a timely manner. Software upgrades typically fix known vulnerabilities, optimize performance, and enhance device stability and functionality.

Troubleshooting: When the device malfunctions and alarms, do not blindly disassemble or forcefully restart it. You should first refer to the fault diagnosis guide in the product manual to investigate the possible causes of the fault. If you are unable to resolve the issue on your own, please contact ALSTOM’s professional technical support personnel or authorized repair agencies in a timely manner.