ABB TP830-1 PLC module

ABB TP830-1 is an excellent PLC module that plays an important role in industrial automation control systems, providing reliable control solutions for various complex industrial scenarios.

Functional Features

Digital input/output function: With 16 channels, it can be used as a digital output module to provide accurate digital control signals for industrial automation systems; It can also serve as a digital input module to receive digital signals from external devices, enabling monitoring and control of industrial processes.

Multi interface design: Equipped with multiple interfaces such as digital input, digital output, analog input, analog output, etc., it can easily connect and communicate with various sensors, actuators, and other devices to meet the diverse needs of different industrial scenarios.

High performance processing capability: Equipped with a high-performance processor, it has fast data calculation and processing speed, and can easily handle complex control algorithms and data processing tasks, ensuring the efficient operation of the system.

Real time monitoring and control: It can monitor and control various industrial processes and equipment in real time, detect and handle abnormal situations in a timely manner, achieve automation control and optimization, and improve production efficiency and product quality.

Reliability and Stability: Using high-quality materials and advanced manufacturing processes, it has undergone rigorous testing and inspection to adapt to different working environment temperature and humidity conditions. It can work stably in the temperature range of -25 ℃ to+60 ℃, with high stability and reliability, and can operate stably for a long time in harsh industrial environments.

Scalability: Supports combination and expansion with other devices, and supports multiple different communication protocols and control methods, making it convenient for users to flexibly integrate and control the system according to actual needs to meet constantly changing production requirements.

Easy to use: Supports plug and play, easy installation, and has a simple and easy to understand interface and operation interface, reducing the user’s threshold for use, reducing installation and debugging time, and facilitating maintenance and management.

Application area

Manufacturing industry: Used for equipment control on production lines, such as robot control, automated assembly, material conveying, etc., to achieve automation and intelligence of the production process, improve production efficiency and product quality.

Process control: In process control systems in industries such as chemical, petroleum, and power, precise control of process parameters such as temperature, pressure, flow rate, and liquid level is carried out to ensure stable operation of the production process and consistency in product quality.

Factory automation: It can be used for the overall automation control system of factories, including workshop lighting control, air conditioning system control, access control system control, etc., to achieve intelligent management of factory facilities, improve the operational efficiency and management level of factories.

Install

Site Planning

Site selection and building requirements: The AC 800M system is designed for harsh industrial environments, introducing requirements for temperature, vibration, cooling, grounding, and other aspects, as well as other requirements such as room lighting independent of equipment power supply, complete process connections, effective grounding, cable wiring that complies with standard installation regulations, available power and other necessary facilities, compliance with standards and laws and regulations, and sufficient space in front of cabinets.

Cable: Introduces the requirements for laying on-site and communication cables, such as maintaining a distance of 10cm (4 inches) from other cables for short distance communication cables, maintaining a distance of 30cm (12 inches) from all power cables connected to AC 800M, and maintaining a distance of 10cm (4 inches) from relevant international immunity standard Category 4 cables; Applications that use shielded cables and situations where unshielded cables can be used; The lightning protection requirements for industrial equipment and power plants, as well as the installation of lightning protection equipment for overhead signal cable laying in large dispersed factories.

Power supply: Under normal circumstances, the power required for the AC 800M controller and related on-site equipment can be obtained from the factory’s standard 120/230V AC main power supply; When using the SD831/832/833/834 power unit, there is no need to use a main grid filter; The main circuit breaker must be installed near the controller installation to immediately and completely disconnect the power supply of the equipment when needed, and installed in an easily accessible and clearly visible location; Equipment connected to 115/230V AC power supply must be equipped with protective grounding (PE); To meet the requirements of IEC61131-2 for PE connection, it is recommended to use 35mm ² (2 AWG) copper wire as the PE conductor for the equipment; Recommended external main power supply fuse rating for standard AC 800M controller configuration, etc; The SD83X series power supply unit can easily handle short-term (<20 milliseconds) power outages that may occur in industrial environments, but to protect certain applications from transient voltage faults, uninterruptible power supply (UPS) equipment needs to be installed; The AC 800M controller will safely shut down in the event of a power failure, during which the application program memory and system clock are backed up by internal batteries. For systems that have not been running for a long time, it is recommended to install an external battery backup unit. After reconnecting to the power supply, the controller will restart and run the application program normally. If unexpected shutdown is not acceptable, it is strongly recommended to fully connect the AC 800M controller to an uninterruptible power supply (UPS) source.

Shell: The protection level of AC 800M and S800 I/O units is IP20, and each unit is individually marked with CE. If a higher IP level is required, an additional shell is needed; The use of additional enclosures usually does not affect the EMC characteristics of the controller; When installing the controller casing, in order to ensure good ventilation, a certain minimum distance should be maintained between the casing and the walls and ceilings; If the enclosure has a removable wall panel, it shall not be removed from any enclosure adjacent to any device that does not belong to the AC 800M controller and its connected S800 I/O; ABB recommends using RM550 (floor standing cabinet) and RE820 (wall mounted cabinet), with a protection level of IP54 and no additional cooling equipment required.

AC 800M unit installed on DIN rail: Due to the natural convection cooling of the AC 800M unit (CPU and communication interface), it can only be installed on a horizontal DIN rail; Each base has a locking mechanism that contacts the DIN rail with the metal backplate, providing an effective grounding connection. The DIN rail serves as the effective grounding for the system; The additional screw ears at the bottom of the base have no electrical function and can be used for additional fastening in environments with excessive vibration; There are two installation methods for the product in the cabinet, namely aluminum profiles with DIN rails or DIN rails installed on appropriately sized metal plates. The aluminum profiles or metal plates should be correctly connected to the protective grounding; Use DIN rails with a height of 7.5mm, referring to the NS 35/7.5 type of EN50022 standard; The interference suppression of external signals is usually directly grounded to the chassis and/or factory grounding, and the factory grounding potential must be stable and clear; The conductive backplate of each module is connected to a metal DIN rail as an electronic grounding conductor between modules, ensuring good grounding connection for internal logic, module EMI immunity, and RF transmission. The DIN mounting rail must have a good connection with the PE of the cabinet; If the AC 800M module is configured as two or more groups interconnected through extension cables, special attention should be paid to ensuring that all groups have good grounding connections for their DIN rails.

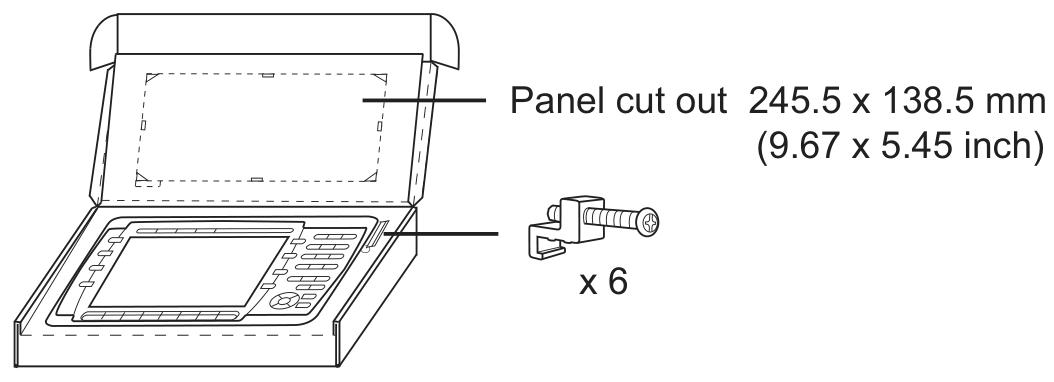

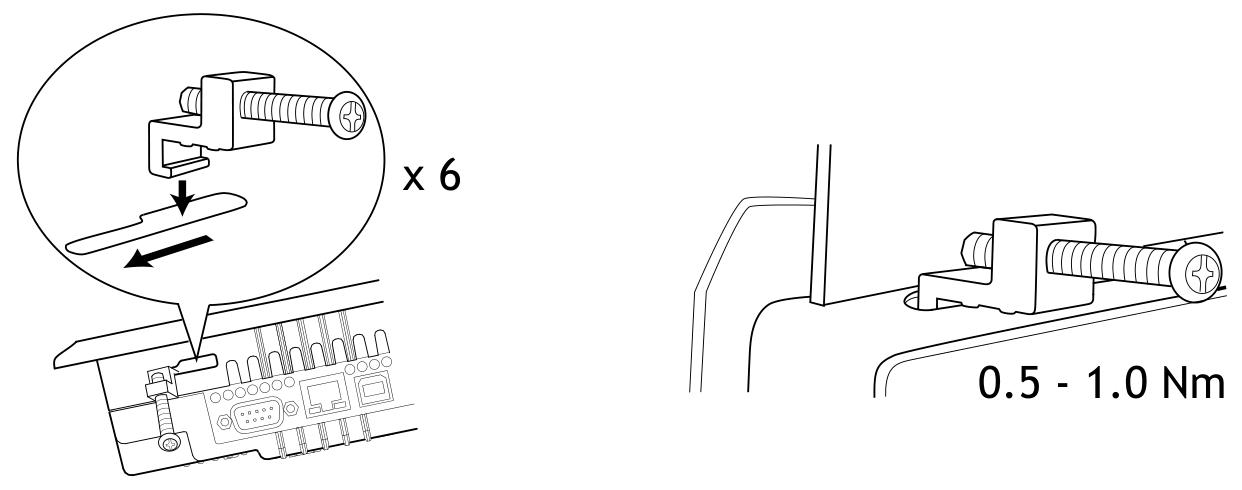

Other installation contents: including specific requirements and steps for installation on metal plates, installation of prefabricated aluminum profiles, as well as various processor units CEX-Bus、 The installation steps and precautions for communication interfaces, power supplies, main circuit breaker units, voting units, external battery units, I/O units, etc., as well as examples of installation in cabinets and installation size requirements for appropriate ventilation.

Configuration

General information: Using the engineering tool Control Builder, hardware (I/O and communication units) can be configured and applications can be created using control languages that comply with IEC 61131-3. The program can be compiled and run offline to facilitate process simulation before ultimately downloading the application to the controller. Control Builder provides a set of options, each with its own set of properties, simply select the option that is closest to the system requirements.

Connect Control Builder: Control Builder is installed on a PC and is usually connected to the AC 800M controller through the CN1 or CN2 ports on the control network and controller. It can also be connected through the COM4 port (RS-232C) on the AC 800M controller using tool cable TK212 and the serial port on the PC. In redundant configuration, Control Builder is connected to the COM4 port of the main CPU, and the backup CPU cannot communicate with Control Builder. PM851/PM851A is limited to one Ethernet (CN1) port and therefore does not support redundant Ethernet. The Control Builder standard does not support CI862, and to use CI862, appropriate system extensions must be installed. To use the FF HI function, the firmware of CI852 unit needs to be upgraded through the Serial Firmware Upgrade Tool. This tool loads special firmware with FF HI function into the controller and manually browses it in the Serial Firmware Upgrade Tool . \ Firmware Files \ SC860rFFHI folder and select firmware. ext.

Connecting to the control network: The control network is a dedicated IP network domain used for real-time data and general system communication between industrial computers, which can be expanded from small networks to large networks containing multiple “network areas” and hundreds of nodes. The controller is installed in the cabinet, and in industrial environments, AC 800M/control network connections must be converted to fiber optic (FO), which can be achieved by installing Ethernet switches with optical and electrical ports.

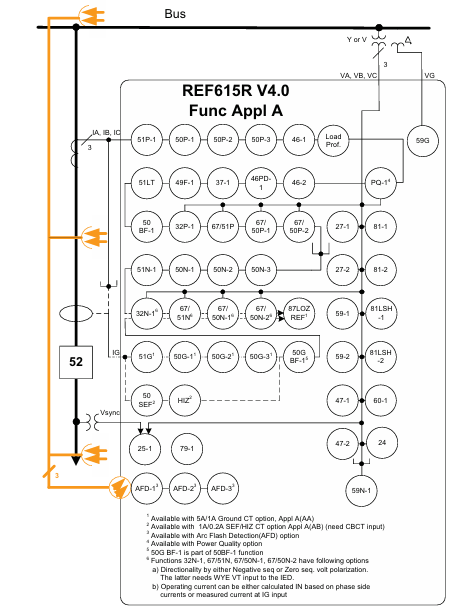

Communication possibility: The processor unit (PM8XX/TP830 or PM891) contains multiple communication ports, such as CN1 and CN2 for connecting to the control network, COM3 for RJ45 port with modem signal, COM4 for connecting to service tools, etc. By adding communication interfaces to CEX Bus, the number of protocols and processor unit ports can be expanded. The document lists the available interfaces and their quantities on CEX Bus.

Controller IP Address: It is recommended to always use the “Factory Reset” command to start an IPConfig session before allocating the expected IP address, in order to clear previously stored backup MAC and IP addresses (if any). Introduced the methods and precautions for setting IP addresses in both single CPU and redundant CPU configurations.

I/O system: There are various methods to connect the I/O system to the AC 800M controller, such as connecting S100 I/O through CI856; By connecting S800 I/O units through Modulus Bus, it supports hot configuration, redundancy at all levels, HART routing, and sequence of events (SOE) during operation. Also introduced ModuleBus、PROFIBUS DP、PROFINET IO、FOUNDATION Fieldbus High Speed Ethernet(FF HSE)、TRIO/Genius Remote I/O、Satt I/O on ControlNet、PROFINET IO via CI871 Waiting for relevant information.

Drive system: ABB standard (Std) and engineering (Eng) drives can be connected to AC 800M in various ways, such as optical Modulus Bus, CI801 and PROFIBUS DP, NPBA-12, RPBA-01 or FPBA-01 PROFIBUS DP adapter modules, and CI854. The relevant parameters and limitations of different connection methods are also introduced.

Power System: The power system configuration of the AC 800M controller is very simple, providing a series of simple circuit diagrams that demonstrate various possibilities of connecting the input main power supply to the 24V DC distribution terminal through the main circuit breaker, power unit, and SS83X voting device. It also introduces the requirements and precautions for power supply to units inside the cabinet, power supply to on-site equipment outside the cabinet, and power supply from external power sources.

Operate

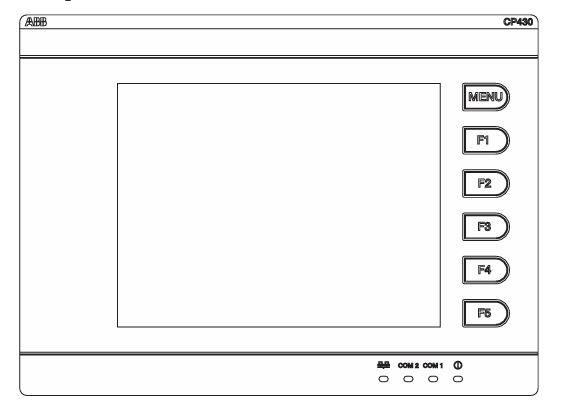

AC 800M Controller (PM8xx): After being equipped with control software, the basic PM8xx/TP830 or PM891 hardware units installed on the AC 800M hardware platform constitute the AC 800M controller. Introduced relevant information on LED indicator lights, switches and buttons, and connectors.

Startup: including reference documents for firmware download, controller IP address, application download, firmware update, and other information; Precautions for CEX bus and CEX module during startup in redundant configuration.

Startup mode: including hot start, cold start, controller reset, and the operation methods and characteristics of cold start and controller reset in redundant configurations.