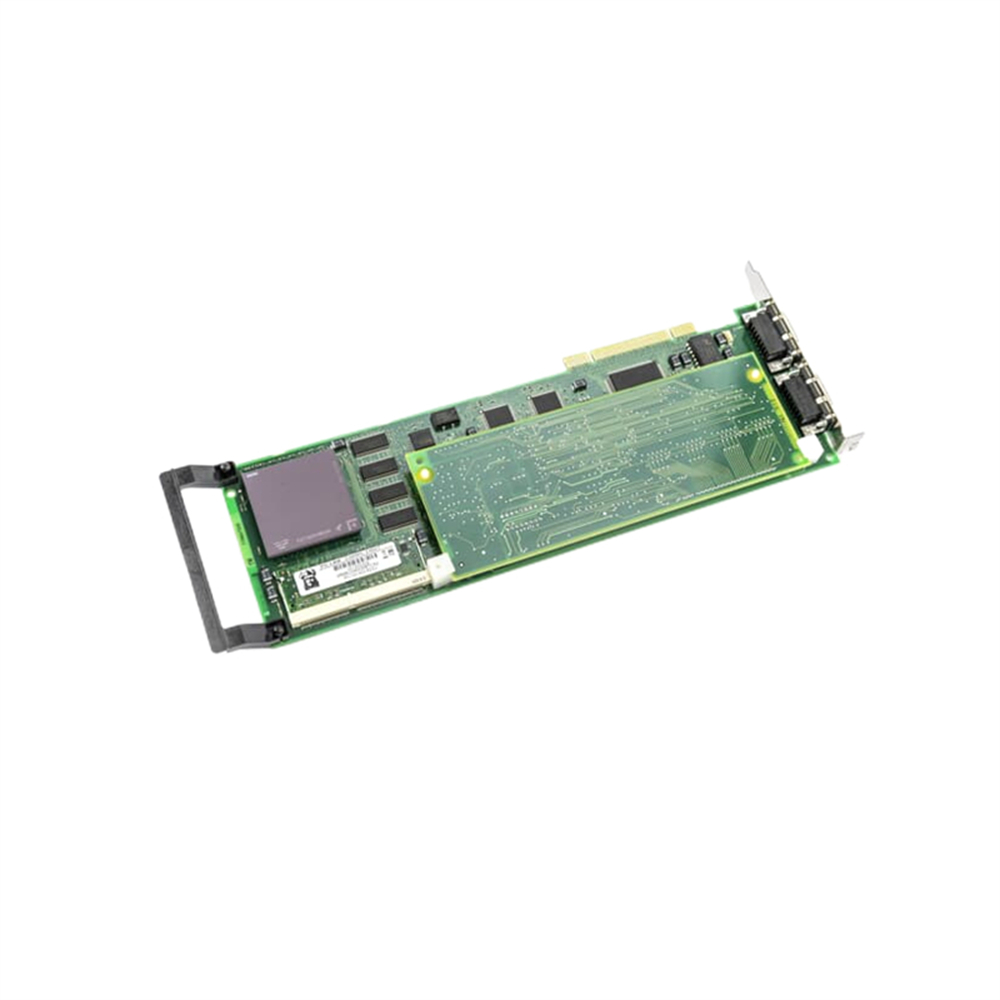

ABB MB510 Program Card Interface

Product overview

The ABB MB510 program card interface (product ID: 3BSE002540R1) is a key component belonging to the ABB control system accessory series, mainly used for connecting and exchanging data between program cards and related control systems. As an important interface device for control and communication, it plays a bridging role in industrial automation control systems, capable of storing, reading, and transmitting programs, providing strong support for stable system operation and program management. This product is non customized, with a minimum order quantity and order multiple of 1 piece.

Basic Product Information

Product ID: 3BSE002540R1

ABB model name: MB510

Product Name: MB510 Program Card Interface

Core credit: 0.00

Country of Origin: Sweden (SE)

Customs tariff number: 85389091

Gross weight: 0.14 kg

Net weight of product: 0.14 kg

Invoice Description: MB510 Program Card Interface

Is it a customized product? No

Packaging grade 1 Gross weight: 0.14 kg

Packaging Level 1 Unit: 1 piece

Component Type: New Product

Sales measurement unit: piece

Inventory location (warehouse): Distribution center, US central warehouse DEOSCEXPU、SGRL4414FEXPU、SELOGVEXPU

Technical information: Program card interface

UNSPSC:39120000

Size and weight

Product net depth/length: 260 mm

Product net height: 20mm

Product net width: 120mm

Category

Control System Products → Control & Communication → AC 400 → AC 400 – Accessories → MB510 Program Card Interfaces MB510 Program Card Interface

Control Systems → Advant OCS with Master SW → Controllers → Advant Controller 450 → Advant Controller 450 Version 2.3 → Control System Accessories

Control Systems → Safety Systems → Safeguard → Safeguard 400 Series → Safeguard 400 1.6 → Unclassified

Control Systems → Advant OCS with Master SW → Controllers → Advant Controller 410 → Advant Controller 410 Version 1.5 → Central Units

Control Systems → Advant OCS with Master SW → Controllers → Advant Controller 450 → Advant Controller 450 Version 2.3 → Central Units

Control Systems → Advant OCS with Master SW → Controllers → Advant Controller 450RMC → Advant Controller 450RMC 2.x → Central Units

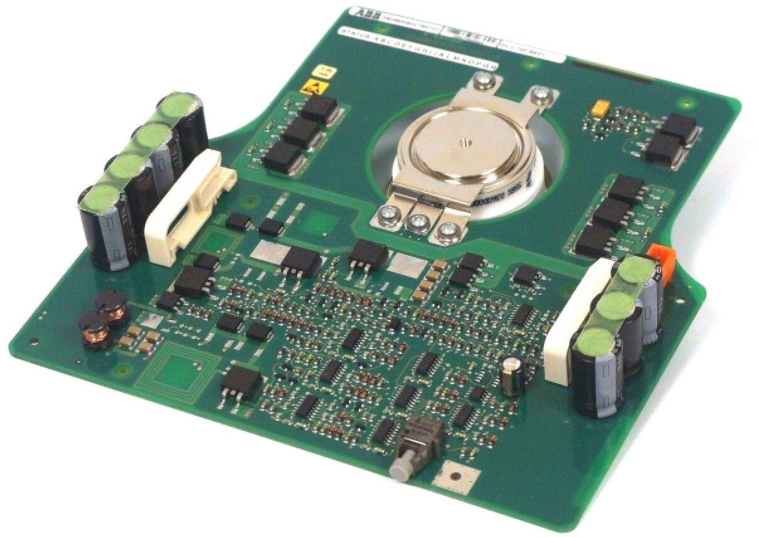

Working principle

The working principle of the ABB MB510 program card interface is mainly to establish physical and data connection channels between the program card and the control system. After the program card is inserted into the interface, the interface identifies the type and status of the program card through internal circuit design, and establishes a data transmission link.

During data transmission, the interface receives program data signals from the program card, undergoes internal signal processing and conversion, converts them into a signal format that the control system can recognize and process, and transmits them to the control system; At the same time, it can also receive program storage, reading and other instruction signals issued by the control system, convert them into signals recognizable by the program card, and control the program card to perform corresponding operations, such as writing program data from the control system into the program card for storage, thereby achieving effective data exchange between the program card and the control system.

Key advantages

Reliable Connection: Adopting high-quality interface design and manufacturing processes, it can provide stable and reliable connections for program cards and control systems, reduce data transmission errors caused by loose connections or poor contacts, and ensure the smooth operation of program loading, storage, and other operations.

Strong adaptability: Specially designed for specific control system suites, with good compatibility with related systems, it can seamlessly integrate into the system without the need for complex debugging and adaptation work, reducing the difficulty and cost of system integration.

Compact and convenient: Its compact size and lightweight weight make it highly flexible during installation and use, able to adapt to different installation space requirements, and also convenient for transportation and storage.

Precautions

Installation operation: During the installation process, it is necessary to ensure that the interface is correctly connected to the program card and control system, and to avoid damage to the interface or related equipment caused by incorrect insertion or misconnection. When installing, pay attention to moderate force to prevent physical damage to the interface caused by excessive force.

Environmental protection: Although the product itself has certain design considerations, it should be installed in a dry, ventilated, non corrosive gas and dust free environment as much as possible during use to avoid environmental factors affecting the performance and service life of the interface.

Compatibility note: Due to the specific compatibility kit of this product, it is necessary to confirm whether it matches the control system kit used when selecting, in order to avoid malfunction caused by incompatibility.

RoHS related: This product does not comply with RoHS standards. In application scenarios with strict requirements for RoHS, this factor needs to be considered in advance to determine whether it is applicable.