Core components of the product

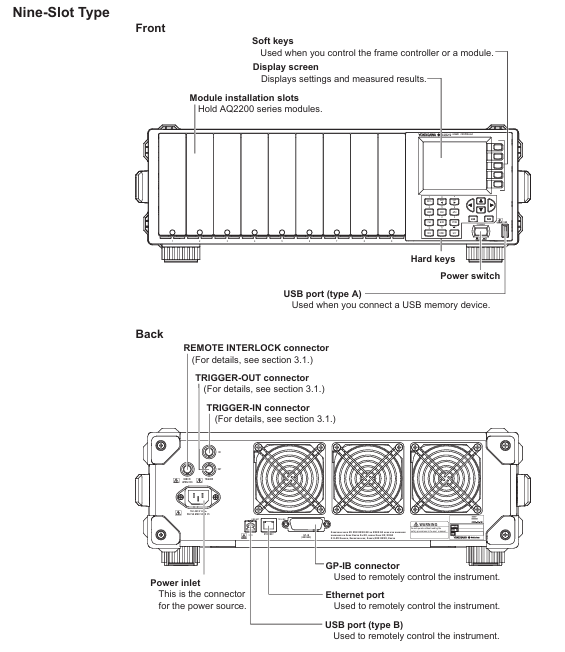

Frame controller: 2 models, responsible for accommodating and controlling modules

AQ2211 (Model 735101): 3 module slots

AQ2212 (Model 735102): 9 module slots

Measurement module: covering the entire process of optical testing, the main types are as follows

Light source module: AQ2200-111(DFB-LD)、AQ2200-112(LS)、AQ2200-141/142(FP-LD)、AQ2200-131/132(Grid TLS)、AQ2200-136(TLS)

Optical sensor module: AQ2200-201/202 (interface module), AQ2200-231/232/241/242 (optical sensor head), AQ2200-211/212/215/221/222 (sensor module)

Other modules: attenuator (AQ2200-311/311A/312/331/332/342), optical switch (AQ2200-411/412/421), BERT (AQ2200-601), optical modulator (AQ2200-621/622), optical receiver (AQ2200-631), etc

Unpacking inspection and installation preparation

3.1 Open box inspection checklist

Frame controller: Confirm that the model (AQ2211/AQ2212), side nameplate are consistent with the order, and there are no scratches/damages on the appearance

Power cord: Match regional standards according to suffix codes, with the following key parameters

Standard rated voltage of suffix code

– UL/CSA、PSE 125V

04R VDE/Korean 250V

-Q British 250V

-Chinese standard 250V

-Brazilian standard 250V

-Taiwan standard 125V

Standard accessories (not covered by warranty)

Interlocking plug (A1288JA, 1 piece), rubber foot pad (A9088ZM, 1 set)

Printed manuals: IM 735101-01EN (start-up guide), IM 735101-73Z2 (download guide), PIM 113-01Z2 (global contact information), etc

Optional accessories (purchased separately)

Accessory Name Model/Part No. Specification

Blank panel AQ2200-901 1-slot size, covering empty slots

AQ2211 Rack Kit 735182-03 Installation of 1 AQ2211 to EIA Standard Rack Left

AQ2212 Rack Kit 735182-09 Installation of 1 AQ2212 to EIA Standard Rack

3.2 Installation Environment and Requirements

environmental conditions

Temperature: 5-40 ℃ (working), -20~60 ℃ (storage)

Humidity: 20~80% RH (no condensation, consistent with operation and storage)

Altitude: working ≤ 2000m, storage ≤ 3000m

Prohibited environment: direct sunlight, strong magnetic field, high static electricity, corrosive gases, severe vibration

Space requirements: Ensure ventilation and avoid internal overheating

Left and right sides: each ≥ 5cm

Rear: ≥ 10cm (exhaust hole)

Above/Below: Reserve cable connection space

Rack installation steps (kit required)

Disassemble the handles on both sides of the instrument (AQ2211, remove the left side)

Remove the bottom 4 foot pads

Remove the sealing tape at the mounting hole of the rack

Apply new sealing tape to cover the mounting holes of the foot pad/handle

Install the rack kit and secure the instrument to the rack

Core security standards

4.1 Electrical Safety (Warning Level)

Power requirements

Designated power cords must be used, with voltage matching the rated value of the instrument (100-240VAC). Exceeding the maximum voltage of the power cord (such as UL/CSA 125V, VDE 250V) is prohibited

The power plug must be inserted into a three core socket with protective grounding, and the use of ungrounded extension cords is prohibited

grounding protection

Before starting up, it is necessary to connect the protective ground and it is forbidden to cut off the internal/external grounding wire

Check if the grounding and fuse are intact. Do not operate if they are damaged

Operation taboos

Prohibited for use in explosive gas/vapor environments

It is prohibited to dismantle the casing (including high-voltage components inside) without authorization. Only qualified personnel from Yokogawa can repair it

Before connecting external equipment, it is necessary to ground it first. Before touching the circuit, turn off the power and confirm that there is no voltage

4.2 Laser Safety

Laser classification and standards

Module model: Laser classification meets key protection standards

AQ2200-112/131/132 Class 1 IEC 60825-1:2014, 21 CFR 1040.10/11 prohibits direct viewing of laser beams

AQ2200-111/141/142/136 Class 1M IEC 60825-1:2007, 21 CFR 1040.10/11 prohibits the use of optical instruments (magnifying glasses, etc.) for observation at<100mm

Laser unlocking process

Connect the included interlock plug (A1288JA) to the Remote INTERLOCK interface behind the frame controller

Press the SYSTEM key to enter the system screen, move the cursor to Lock, and press ENTER

Enter the default password ‘1234’ and press ENTER

Set Lock to Off and press OK to confirm (laser output can only be turned on after unlocking)

4.3 Environmental Protection and Compliance

WEEE Directive (EEA and UK): Prohibition of mixing household waste, contact local Yokogawa office for disposal

Battery Directive (EEA and UK): Lithium batteries must be collected separately and replaced. Contact the local Yokogawa office for replacement

RoHS compliance: The instrument itself complies with EU RoHS, but if incompatible modules (such as AQ2200-111, AQ2200-131, etc.) are installed, it becomes invalid. The list of incompatible modules can be found in Section 5.1

Taiwan region: Information inquiry on restricted substances for power cord A1100WD: https://tmi.yokogawa.com/support/service-warranty-quality/product-compliance/

Operation process guide

5.1 Module installation and uninstallation

Installation steps

If there is a blank panel in the slot, loosen the screw → slide down to remove the panel

Press the unlock button on the module panel and lift the locking lever

Align with the slot guide rail and slowly insert the module until it is fully seated

Slowly press the lever until you hear a “click” sound (2/3 slot module needs to tighten the bottom fixing screw)

Uninstalling steps

If it is a 2/3 slot module, first loosen the bottom fixing screw

Press the unlock button and gently lift the lever to unlock

Slowly pull out the module (protrude about 1cm, then pull it out by hand)

Hot swappable instructions: Modules can be installed/uninstalled while the frame controller is turned on. If a non SUMMAY/DETAIL screen is displayed during uninstallation, it will automatically switch to these two screens

5.2 Cable Connection

Fiber optic connection

Cleaning the fiber optic end face: Soak the cleaning paper in isopropanol, press and rotate the end face to wipe, then dry it with dry cleaning paper, and finally blow away residual dust with compressed air

Connection rule: The ANGLED PC ONLY interface is only connected to APC type fiber optic cables and is prohibited from connecting other types (to avoid damaging the plug)

Connector adapter: such as AQ9441 (for FP-LD module), AQ9335C (for sensor module), align the guide pin/hole connection according to the manual steps, and lock the lever

electrical connection

Coaxial cable: used for modules such as BERT and optical modulators. Before connecting, confirm that the signal output is turned off and tighten the connector with a torque of 0.9N-m

Power cord: Confirm that the instrument switch is turned off, connect it to a three pin grounded socket, and ensure that the voltage matches the rated value

Key module connection example (BER test)

BERT module (AQ2200-601) DATA OUT → Optical modulator (AQ2200-621/622) DATA IN

Light modulator LD IN → Light source module (AQ2200-111 PMF type) laser output

Optical modulator OPT OUT → DUT → Optical receiver (AQ2200-631) OPT IN

Optical receiver DATA OUT → BERT module DATA IN 1 (CDR)

5.3 Startup and Screen Operation

boot process

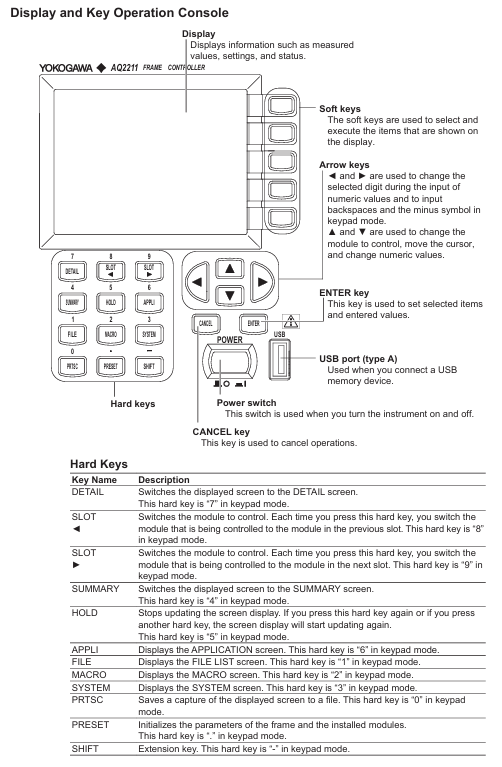

Confirm that the power connection is correct, press the POWER switch on the front panel of the frame controller

The instrument automatically performs self check, and after passing the test, it displays the SUMMAY screen (global module information) or Detail screen (individual module details)

Preheating requirement: To ensure measurement accuracy, it is recommended to preheat for at least 1 hour after turning on the machine

screen operation

SUMMAY screen: The blue background represents the “current module” (modifiable parameters), the light blue background represents the “current parameters”, and the empty slot displays “NO MODULE”

Detail screen: The top displays the current module slot, allowing you to view/modify all parameters of the module (such as wavelength and attenuation values)

Hard key function (key buttons)

Hard key function keyboard mode corresponds to numbers

Switch to Detail Screen 7

SLOT ◄/► Switch current control module 8/9

Switch to SUMMAY screen 4

HOLD pauses screen updates, press again to resume 5

SYSTEM: Enter the system settings screen (date, password, etc.) 3

Maintenance and troubleshooting

6.1 Daily Maintenance

Cleaning requirements

Body: Wipe with a dry soft cloth after power failure. Do not use chemicals such as benzene or diluents (to avoid discoloration/deformation)

Optical interface: Clean with isopropanol and cleaning paper, and only use compressed air to remove dust from the sensitive surface of the sensor head (wiping is prohibited)

Electrical interface: Use compressed air to blow away dust, without using interface cover protective cap/terminal

Regularly replace parts

Suggested replacement cycle note for part name

Cooling fan for 40000 hours to ensure ventilation and avoid internal overheating

Lithium batteries will also be consumed even when the instrument is powered off for 3 years

ATTN module shutter 150000 times suitable for AQ2200-311/311A/312/331/332

LCD backlight for 30000 hours (default brightness 5) needs to be replaced when the brightness drops to half

Calibration requirements

Conventional module: It is recommended to calibrate once a year

AQ2200-111 (DFB-LD): Calibrate every 6 months due to semiconductor characteristics

Calibration method: Contact the Yokogawa dealer to adjust the parameters simultaneously

6.2 Troubleshooting

Common Problems and Solutions

Possible causes and solutions for the problem phenomenon

The instrument cannot be turned on. The power cord is not properly connected and the voltage does not match. Check the power cord connection and confirm that the voltage is between 90-264VAC

Laser lock without output, interlock plug not connected, unlock according to the process (password 1234)

PPG-ED cannot synchronize. The cable is not properly connected and the PPG and ED parameters do not match. Check the cable and confirm that the pattern and PRBS length of PPG and ED are consistent

OE displays LOS alarm for fiber not connected and low input power. Check the fiber connection and add an optical amplifier to increase power

Key error codes

Error code description and solution measures

1014 frame controller and module firmware version do not match. Update firmware to the latest version (contact dealer for information)

1100 laser output locking connection interlock plug, unlocking laser output

1266 Input power exceeds the maximum limit and reduces input power to the specified range (refer to module parameters)

Fault contact preparation: The instrument model, serial number, firmware version, operating steps at the time of the fault, and screen display need to be provided

Firmware update

7.1 Frame Controller Firmware Update

preparation

Download the latest firmware, rename it to “aq221xlz. bin”, and place it in the USB root directory

Disconnect all external devices and only retain USB (direct connection, not through Hub)

Update steps

Turn off the power of the frame controller and plug in the USB

Press and hold the soft key at the top of the front panel, while pressing the POWER switch to turn on the device

The screen displays the update progress, and after completion, it prompts “Flash Update Complete”, and the instrument automatically restarts

After restarting, remove the USB and confirm the version by pressing SYSTEM → Soft Version View

7.2 Module firmware update

preparation

Download the latest firmware of the module and place it in the “module” folder on the USB (without renaming)

Insert the USB into the USB Type A port on the front panel of the frame controller

Update steps

Press the SYSTEM key → move the cursor to “Module Update” → press ENTER

Use the arrow keys to select the module that needs to be updated (the checkbox turns black) → Press the ‘Update Execut’ soft key

Display update status (Executing/Complete/Failed), prompt “Please Restart System” after completion

Restart the frame controller and confirm that the module version update is successful

Leave a comment

Your email address will not be published. Required fields are marked *