Product Overview

The document focuses on two core industrial products of ABB, namely the Advant Controller 250 modular controller and the QABP series low-voltage high-efficiency variable frequency dedicated motor. The former is aimed at industrial distributed control scenarios, while the latter provides rich functions and customized options for various industrial variable frequency speed regulation needs, meeting the needs of multiple industries.

Advance Controller 250 Controller

(1) Product positioning and core advantages

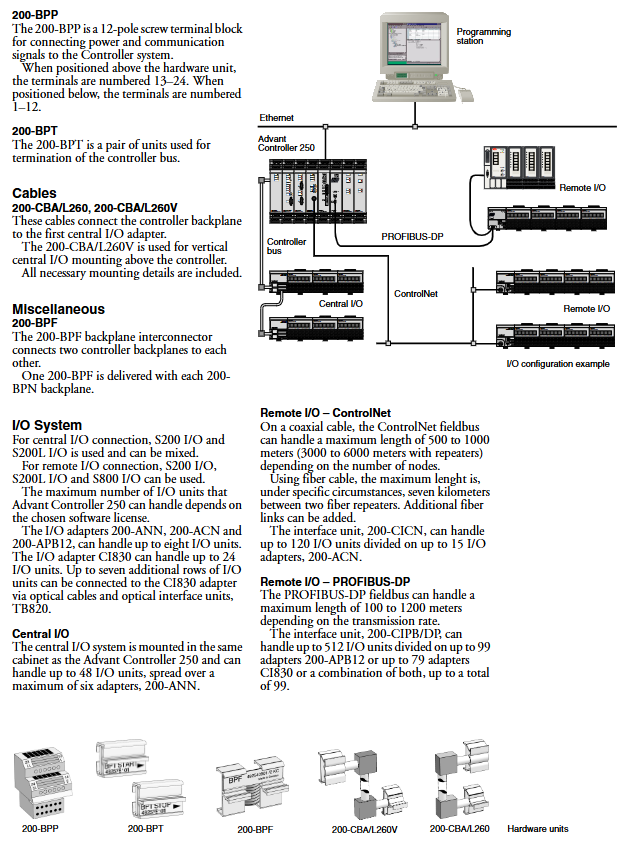

Positioning: Compact modular industrial controller suitable for distributed control systems, supporting local and remote I/O expansion.

Core advantages: Modular design for easy scalability, multi protocol compatibility, support for remote programming, DIN rail installation to reduce maintenance costs.

(2) Core hardware composition

Hardware type, key models/specifications, core functions

Controller units PM253 (16.7MHz), PM254 (28.8MHz), PM255 (50MHz) 32-bit processor+FPU, supporting logic/PID control, with battery backup RAM

Power supply units 200-PSMG (main power supply), 200-PSSG (slave power supply) 24V DC input, output 7-9V DC, main power supply provides bus clock

Communication interfaces such as 200-CIPB/DP (PROFIBUS-DP) and 200-ICN (ControlNet) support multiple bus protocols, enabling remote I/O and system communication

Backboard and Terminal 200-BPN (2-slot backboard), 200-BPP (12 pole terminal) support up to 8 backboards (16 units), and the terminals are compatible with 0.5-2.5mm ² wires

(3) Core technical parameters

Category parameter details

Power supply requirement: 24V DC (19.2-30V DC), ripple ≤ 5%

Environmental conditions: working temperature of 5-55 ℃, storage temperature of -25~70 ℃, humidity ≤ 90% (no condensation)

Protection level IP20

Communication performance: PROFIBUS-DP has a maximum transmission distance of 1200m, while ControlNet fiber has a maximum transmission distance of 7km

I/O capacity up to 512 remote I/O units (PROFIBUS-DP interface)

(4) Software and Features

Programming software: Control Builder (ControlIT), supports Windows 2000 system.

Core functions: Logic functions (IEC 61131-3 standard), PID control, alarm detection and printing, multi protocol communication.

Programming method: Supports remote programming via Ethernet (MMS protocol) or serial port (PPP protocol).

QABP Series Variable Frequency Special Motor

(1) Product positioning and core advantages

Positioning: A low-voltage high-efficiency variable frequency dedicated motor designed for the Chinese market, with a fully enclosed three-phase squirrel cage structure.

Core advantages: IE2/IE3 high energy efficiency, F-class insulation (B-class temperature rise), anti axis current design, rich customization options, and multi industry adaptability.

(2) Core technical parameters

Category parameter details

Energy efficiency levels IE2 and IE3 (compliant with IEC 60034-30-1:2014)

Machine base number and power machine base number 71-355mm, power range 0.18kW-355kW

Number of poles and speed 2/4/6/8 poles, synchronous speed 3000/1500/1000/750r/min

Protection and insulation protection level IP55 (optional IP56/IP65), insulation level F (temperature rise level B)

Operating environment working temperature -20~65 ℃, altitude ≤ 1000m, corrosion protection level C3 (medium)

Overload capacity 1.5 times rated current, lasting for 2 minutes

(3) Structure and Installation Design

Core structure: cast iron base/end cover, copper stator winding, die cast aluminum rotor, deep groove ball bearings (optional cylindrical roller bearings).

Installation method: Supports feet (IM B3), flanges (IM B5/B14), feet+flanges (IM B34/B35).

Junction box: IP55 protection, 71-132 machine base can rotate 4 × 90 °, 160-355 machine base can rotate 2 × 180 °, convenient for wiring.

(4) Key configurations and customization options

Optional accessories:

Brakes: UHT B, INTORQ BFK458, etc. (applicable to H71-225 machine base).

Encoders: Leine&Linde RHI503, HUBNER HOG10, etc.

Cooling method: Standard IC411 (self fan cooling), optional IC416 (independent fan).

Variable code: Covering customized requirements such as extended warranty (865=1 year, 530=2 years), protection upgrade (158=IP65), special lubrication (039=low temperature resistance), etc.

(5) Applicable scenarios

Suitable industries: papermaking, metallurgy, mining, lifting, wind power yaw, rubber and plastic, textile, food and beverage, chemical, water treatment, HVAC, etc.

Typical applications: Variable frequency speed regulation scenarios for pumps, fans, compressors, conveyors, mixing equipment, etc.

Leave a comment

Your email address will not be published. Required fields are marked *