The official use manual of Bosch Rexroth MSK series synchronous servo motors (including 15 frame sizes and models such as MSK030/040/050) (March 2021), which focuses on safety specifications, product parameters, transportation and storage, assembly wiring, commissioning and operation, maintenance and repair, and environmental protection disposal, defines key specifications such as motor protection level IP65 (optional IP67), ambient temperature 0-40 ℃, insulation level 155, and bearing service life 30000 hours, specifies two installation methods of flange/anchor, power supply/encoder/coolant connection requirements, commissioning measures after long-term storage, and troubleshooting procedures, provides full life cycle operation guidance for professionals, and products comply with low-voltage directive 2014/35/EU and other standards.

Core technical parameters

Parameter category, specific specifications, remarks

Protection level IP65 (standard), IP67 (sealed air accessory) motor housing/output shaft in plugged in state

Environmental conditions: working temperature 0-40 ℃, storage temperature -20~+60 ℃, installation height 0-1000m

Insulation class 155 (EN 60034-1)-

Bearing life nominal L ₁₀ h=30000 hours Permanent lubrication deep groove ball bearings

Sound pressure level < 75dB (A)-

Installation types IM B5 (flange drive side) and IM B35 (foot assembly) comply with EN 60034-7

Encoder type: Single cycle (S1/S2/S3), multi cycle (M1/M2/M3) signal period 16-2048, supporting Hiperface/EnDet 2.1

Keep the brake optional, 24V DC ± 10%, torque 10.0Nm, electric release type

Cooling method: natural convection, surface ventilation (fan unit), liquid cooling (FN model), liquid cooling inlet pressure ≤ 6bar

Key points of safety regulations

(1) Electrical safety

Only skilled electricians are allowed to operate. Before starting work, power off, prevent accidental closing, ground short circuit, and shield adjacent live parts.

When the rotor of a permanent magnet motor rotates, a voltage greater than 60V will be generated at the terminal, and the motor must be stopped before operation. It is forbidden to plug or unplug connectors while they are live.

Encoder, KTY84 and other components contain electrostatic sensitive devices (ESD) and must comply with anti-static measures.

(2) Mechanical safety

Suitable equipment (lifting eye bolts) must be used for lifting. It is strictly prohibited to walk under suspended loads or to grip shafts or fan covers during lifting.

Rotating components need to be equipped with cover plates, and the longitudinal axis needs to be mechanically locked or externally braked to prevent sinking after stopping the machine.

When installing transmission components (couplings/pulleys), it is forbidden to strike the shaft end to avoid exceeding the allowable radial/axial force.

(3) Special protection

Electromagnetic fields pose health risks to wearers of pacemakers and metal implants. Such individuals are prohibited from approaching and should consult a doctor.

The surface operating temperature of the motor may exceed 70 ℃, and it needs to be cooled for at least 15 minutes before touching. If necessary, anti contact protective devices should be installed.

Recharging/disassembling/using open flames is prohibited for batteries, and discarded batteries must be separately recycled.

Transportation and Storage Standards

(1) Transportation requirements

Original packaging is required, in accordance with DIN EN 60721-3-2 classification (2K2, 2B1, etc.), transportation temperature -20~+80 ℃, relative humidity ≤ 75% (+30 ℃).

Before transporting liquid cooled motors, it is necessary to drain the coolant to prevent damage from frost; Fix the lifting ring bolts during lifting to avoid strong vibrations.

(2) Storage requirements

The storage environment should be dry, dust-free, vibration free, and dark, with a temperature of -20~+60 ℃, a relative humidity of 5-95% (no condensation), and no salt spray.

Long term storage measures (table):

Storage duration, motor debugging measures, cable/joint debugging measures

Visual inspection in January showed no damage

Replace the brake surface in December, inspect the electrical contacts, run for 1 hour without load (800-1000rpm) to check the electrical contacts, and visually inspect the cable sockets

Additional replacement of bearings, encoders, and measurement of insulation resistance in June-

Assembly and connection specifications

(1) Installation method

Flange assembly (table):

Installation hole diameter (mm), screw specification, tightening torque (Nm), washer requirements

4.5 M4 × 20 3 None

6.6 M6 × 20 10.1 None

9 M8 × 20 24.6 requires a washer

11 M10 × 30 48 requires washer

14 M12 × 40 84 requires a washer

18 M16 × 35 206 requires a washer

Foot assembly: Align the motor shaft with the centerline of the connecting shaft. Radial force is only effective within ± 15 ° of the vertical installation surface. It is prohibited to transmit force to the foot through gears.

(2) Wiring specifications

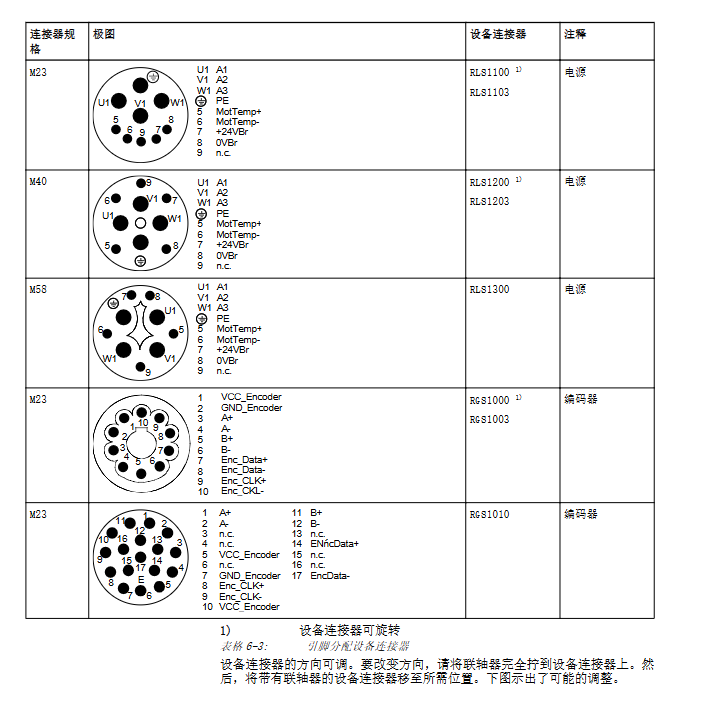

Power connection: Supports M23/M40/M58 connectors or junction boxes (RZK3100/RKL1200, etc.), wire cross-sectional area of 1.5-35mm ², tightening torque of 2.5-3.8Nm.

Encoder connection: 8-16 pole connector, the shielding layer needs to be reliably grounded, the equipment connector can rotate 210 °~220 °, and the maximum tightening torque is 12-18Nm.

Coolant connection (liquid cooling model): The inlet/outlet can be freely distributed. The frame size is 071/075, and the tightening torque is 14-15Nm. 101/133 is 18-20Nm. It is prohibited to use Teflon tape for sealing.

(3) Accessory assembly

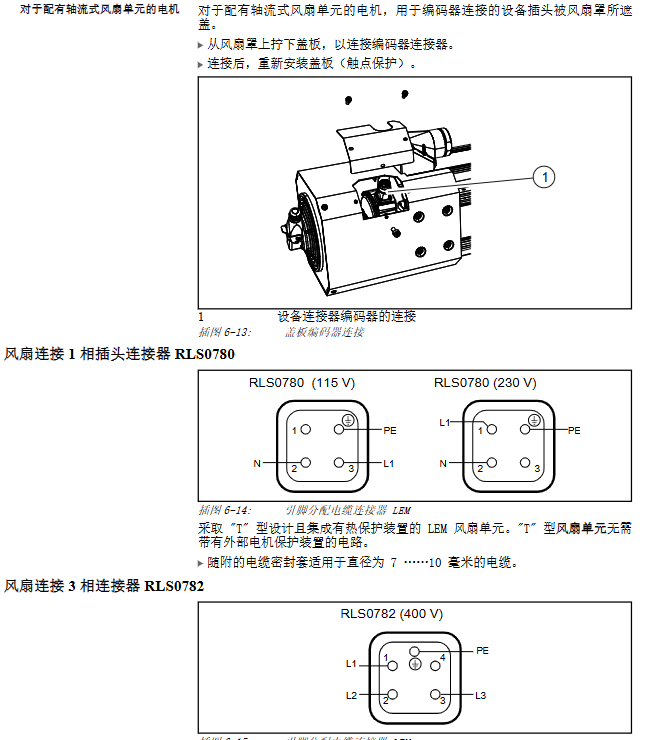

Fan unit: Supports 115V/230V (single-phase) and 400V (three-phase), connected according to the nameplate voltage, integrated with thermal protection device, and the fan cover needs to reserve an encoder connection cover plate.

Air pressure connector: Working pressure of 0.1 ± 0.05 bar, SUP-M01-MSK (encoder side)/SUP-M02-MSK (power side) kit is required, with a tightening torque of 1.3-3.1 Nm.

Debugging and Running

(1) Debugging prerequisites

Confirm the storage duration of the motor and implement corresponding debugging measures; Check that all connectors are securely connected and that the brake voltage is 24V ± 10%.

Verify that the brake function is normal, the protection key is fixed, and there are no residual transport locking devices.

(2) Operation monitoring

During operation, it is necessary to comply with the environmental and technical parameters in the project planning manual, and monitor abnormal noise and vibration increments.

Regularly check the cleanliness of the motor/fan, the sealing of the coolant interface, pay attention to the diagnostic error messages of the controller, and stop the drive in case of abnormalities.

(3) Troubleshooting (Table)

Possible causes and solutions for the fault phenomenon

Motor not running, controller enable signal missing, power supply voltage missing, brake not released activation enable signal, check power supply, verify brake activation status

Abnormal vibration, poor balance of coupling components, insufficient alignment of shaft end attachments, loosening of installation screws, rebalancing of components, calibration of attachments, and locking of screws according to specifications

High operating noise, foreign objects inside the motor, damaged bearings, and shutdown. Contact the manufacturer for repair after shutdown

Motor temperature exceeds rated load, heat dissipation is damaged, temperature sensor is not connected to reduce load, clean motor/check fan/cooling circuit, connect sensor

Maintenance and environmental disposal

(1) Maintenance points

Cleaning and maintenance: Regularly (no later than 1 year) clean the surface of the motor to avoid dust covering and affecting heat dissipation; The connecting cable needs to be checked for damage, and the drag chain needs to be checked for defects.

Spare parts replacement: It is recommended to replace the bearings after 30000 hours; Visually inspect the shaft sealing ring after 5000 hours and replace it if necessary; Only use Rexroth original spare parts.

(2) Environmental disposal

Product Ingredients: Steel, Aluminum, Copper, Permanent Magnet, Electronic Components, Can be Classified and Recycled; The packaging materials (cardboard/wood/polystyrene) can be routinely recycled.

Permanent magnets need to be demagnetized before disposal, and it is prohibited to transport magnetized rotors; Waste batteries need to be recycled according to the national dedicated system to avoid pollution.

Leave a comment

Your email address will not be published. Required fields are marked *