The official technical information of Bosch Rexroth MDD series digital AC servo motors and DIAX04 series HDD/HDS second-generation drive controllers revolves around product technical parameters, installation configuration, safety specifications, wiring requirements, transportation and storage, and service support. It clearly defines the applicable scenarios for automation equipment such as machine tools, robots, and packaging machinery, and specifies in detail the rated torque (such as MDD 115 maximum continuous torque 57Nm), speed (such as MDD 021 rated speed 10000min ⁻¹), protection level (mainly IP 65), wiring specifications, and safety operation points of each model, providing comprehensive technical guidance for equipment selection, installation, and maintenance.

1、 Basic Information

Covering products

MDD series: 9 models of digital AC servo motors, including MDD 021/025/041/065/071/090/093/112/115, each with different length specifications (A/B/C/D), supporting natural cooling or surface cooling.

DIAX04 series: Second generation HDD/HDS drive controller, including HDD02.2-W040N-HD32, HDS02.2-W040N and other models, modular design, supporting servo and spindle drive functions.

Core applicable scenarios

Commonly applicable to automation scenarios such as machine tools, textile/printing/packaging machinery, robots, and handling equipment.

MDD motors are classified according to their performance into precision types (such as 090/112), high dynamic types (such as 065/093), and compact types (such as 021/025), which are suitable for different load requirements.

2、 Core security requirements

(1) Electrical safety

High voltage and discharge protection

After the DIAX04 driver is powered off, it is necessary to wait for 5 minutes for the capacitor to discharge. After the MDD motor related equipment is powered off, it is necessary to confirm that the voltage is below 50V before operation.

The grounding conductor needs to use copper wire with a cross-sectional area of ≥ 10mm ², permanently and reliably connected, with a leakage current greater than 3.5mA.

Wiring safety

Do not plug or unplug connectors while powered on. The minimum wire diameter for the control voltage line (24V) is 1mm ², and the minimum wire diameter for loop transmission is 2.5mm ².

The motor cable should use the original factory specifications, with a maximum length of 75m for MDD motor cables, and the shielding layer should be reliably grounded.

(2) Mechanical and Sports Safety

Prevention of dangerous sports

Safety fences, light curtains, emergency stop switches (verified for effectiveness before starting) need to be installed, and additional mechanical locking or external braking devices are required for the vertical axis.

The standard motor brake of MDD motor does not meet the requirements of personnel safety protection and requires additional measures.

Handling and assembly

Heavy duty motors (such as MDD 115 weighing 60kg) require the use of suitable lifting equipment to avoid compression and shear injuries, and protective equipment such as goggles and safety shoes should be worn.

(3) Special protection

Electromagnetic and High Temperature Protection

Pacemakers and metal implant wearers are prohibited from entering the equipment operation/installation area. If they need to enter, they must consult a doctor.

After the equipment is running, the temperature of the casing may exceed 60 ℃. The MDD motor can cool down for up to 140 minutes and needs to be cooled down or operated with protective gloves.

environmental protection

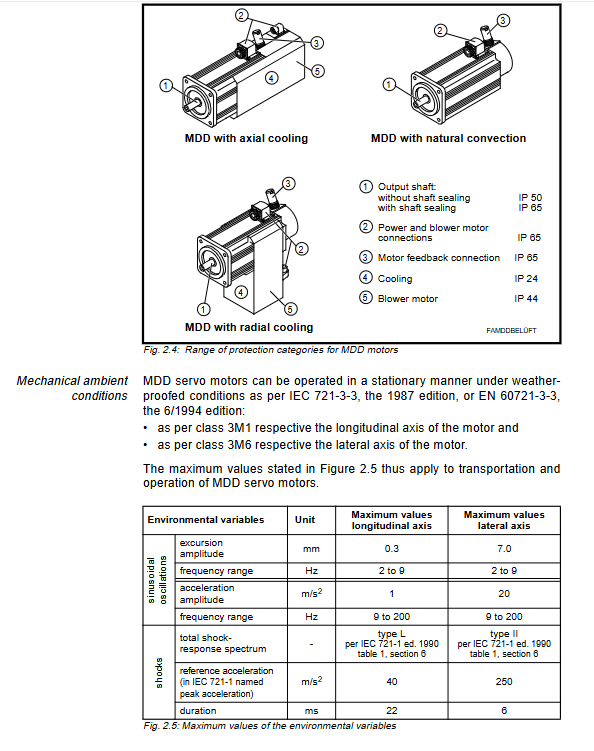

The protection level of MDD motors is mostly IP 65, and some models (such as MDD 021) have an output shaft protection level of IP 50, which is not suitable for dusty and wet environments.

3、 Comparison of core technical parameters

(1) Key parameters of MDD series motors (representative models)

Model Rated speed (min ⁻¹) Continuous torque (Nm) Peak torque (Nm) Protection level Weight (kg)

MDD 021 A 10000 0.30 1.3 IP 50 (output shaft) 1.0

MDD 065 D 4000/6000 2.7/2.7 7.8 IP 65 5.3

MDD 115 D 1500/2000 57.0/57.0 177.3 IP 65 60

(2) Key parameters of DIAX04 series drivers (representative models)

Model Rated current (A) Cooling method Interface type Suitable for motor

HDD02.2-W040N-HD32 40 air-cooled (built-in blower) SERCOS, analog MKD/MHD/MDD series

HDS03.2-W100 100 100 air-cooled SERCOS/ANALOG high-power MDD motor

4、 Installation and wiring specifications

(1) Installation requirements

Spacing and Layout

The minimum distance between the top of MDD motor is 150mm, and the minimum distance between the bottom is 80mm; the minimum distance between the bottom of DIAX04 driver is 100mm to ensure heat dissipation.

The control cabinet should be well sealed to avoid condensation water, and a cooling system should be installed when the ambient temperature exceeds 45 ℃.

Fixed and directional

MDD motors support IM B5 (flange through-hole) and IM B14 (flange thread) installation, which can be installed in any direction. Some models need to avoid liquid accumulation on the output shaft.

Heavy duty motors (MDD 112/115) require the use of lifting screws or cranes for handling, and it is prohibited to grip the blower area.

(2) Wiring specifications

MDD motor wiring

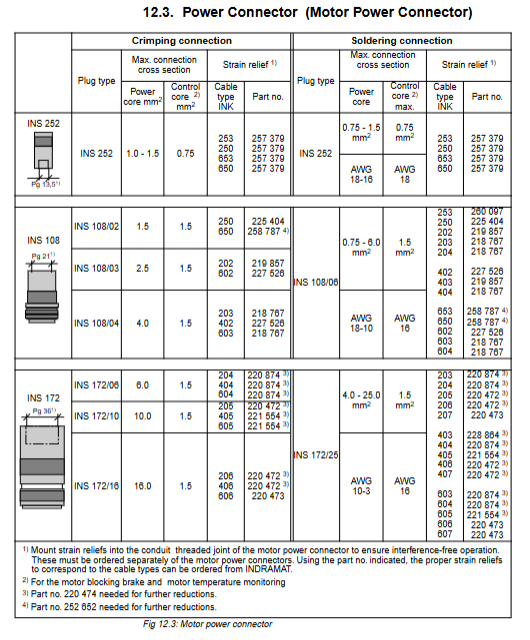

Power connection: including power cable, temperature sensor (PTC), brake device wiring, wire diameter 0.2-25mm ², tightening torque 2.5-3.0Nm.

Feedback connection: 12 pin flange socket, supports Resolving Feedback (RSF) or Digital Servo Feedback (DSF), with a maximum resolution of 2097152 increments per revolution.

DIAX04 driver wiring

Key interfaces: X5 (DC bus/motor/power supply), X6 (brake/temperature monitoring), X10/X11 (SERCOS fiber), X12 (external input).

The default data rate of the fiber optic interface is 2Mbaud, which can be switched to 4Mbaud, and a specified model of fiber optic cable is required.

5、 Transportation, storage, and operation and maintenance

(1) Transportation and Storage

Transportation requirements

The motor needs to be fixed in a tray or cardboard box, secured with square wood and metal straps to avoid collisions, and heavy-duty motors require specialized lifting equipment.

Drivers should avoid severe vibrations and be protected against dust and moisture during transportation.

Storage conditions

Temperature range: -25 ℃~+85 ℃ (MDD motor), -30 ℃~+80 ℃ (cable accessories).

When storing, the protective covers of the connectors and output shafts should be retained until they are removed before installation.

(2) Operations and Services

fault diagnosis

Obtain fault information through device status display lights and SERCOS interface error signals, refer to the corresponding troubleshooting guide.

The MDD motor temperature sensor (PTC) monitors the winding temperature, and the controller will generate an error prompt when overheating occurs.

Service Support

International service hotline:+49 (0) 172-6600406,+49 (0) 171-3338826, supporting 7 × 11 hour service (weekdays).

Repair requires providing information such as product model, fault symptoms, fault codes, etc. The returned product must be accompanied by a repair card.

6、 Model coding rules (example)

(1) MDD motor model (MDD 021 B-N-100-N 2 G-032 F B 0)

Motor series: MDD

Motor size: 021

Motor length: B

Cooling method: N (natural cooling)

Rated speed: 100 (10000min ⁻¹)

Balance level: N (standard level)

Feedback type: G (Resolver feedback)

Output shaft: F (optical axis, no shaft seal)

Braking device: 0 (no braking)

(2) DIAX04 Drive Model (HDS03.2-W100-HS01-FW)

Product series: HDS

Product Line: 03

Version: 2

Cooling method: W (air-cooled)

Rated current: 100 (100A)

Controller family: H (DIAX04)

Interface type: S (SERCOS)

Firmware: FW (to be ordered separately)

Leave a comment

Your email address will not be published. Required fields are marked *