The ABB QABP series low-voltage high-efficiency variable frequency dedicated motor is a fully enclosed three-phase squirrel cage motor designed specifically for the Chinese market. Its efficiency covers IE2/IE3 energy efficiency levels, with a machine base size range of 71-355mm, 2-8 poles, protection level of IP55, insulation level of F (B-level temperature rise), suitable for 380V 50Hz power supply, supports multiple installation methods of foot/flange/foot+flange, adopts corona resistant composite enameled wire and proprietary variable frequency control technology, can effectively solve shaft current problems, and is widely used in multiple industrial fields such as papermaking, metallurgy, mining, etc. It provides rich optional configurations (brakes, encoders, special lubrication, etc.) to meet the needs of different variable frequency speed regulation scenarios.

Product Overview

Basic positioning

The QABP series is a low-voltage and high-efficiency variable frequency motor developed by ABB for the Chinese market. It is a fully enclosed three-phase squirrel cage structure and is mainly used for variable frequency speed control drive in industrial scenarios.

The product complies with IEC international standards and Chinese GB standards. The manufacturer has passed ISO9001 quality certification and ISO14000 environmental standards, and the quality and environmental performance meet the standards.

Core strengths

Efficient and energy-saving: The energy efficiency level reaches IE2/IE3, reducing operating energy consumption.

Stable and reliable: using high-grade corona resistant composite enameled wire to improve the insulation level of the winding, proprietary technology to solve shaft current problems, and reduce winding and bearing failures.

Flexible adaptation: supports multiple installation methods and multi pole selection, provides rich customized configurations, and can meet the special needs of different industries.

Strong protection: IP55 protection level, suitable for harsh industrial environments, optional higher protection level (IP56/IP65).

Core technical parameters

(1) Summary of Key Parameters

Category parameter details

Power range 0.18kW (71 frames with 6 poles)~355kW (355 frames with 2/4 poles)

frame size 71、80、90、100、112、132、160、180、200、225、250、280、315、355mm

Number of poles and speed: 2-pole (3000r/min), 4-pole (1500r/min), 6-pole (1000r/min), 8-pole (750r/min)

Insulation and temperature rise insulation level F, temperature rise level B (rated environment 40 ℃, maximum allowable temperature rise 80K)

Protection level standard IP55, optional IP56 (variable code 403), IP65 (variable code 158)

The standard cooling method is IC411 (self fan cooling), and IC416 (independent fan cooling, variable code 183) is optional

Operating environment working temperature -20 ℃~65 ℃, storage temperature -25 ℃~75 ℃, humidity ≤ 95% RH (no condensation)

Overload capacity 1.5 times rated current for 2 minutes (at rated voltage and frequency)

(2) Energy Efficiency and Efficiency Data

IE2 energy efficiency: efficiency range 68.5%~95.3% (full load), in compliance with IEC 60034-30-1:2014 standard.

IE3 energy efficiency: Efficiency range of 73.5%~96.3% (full load), with better energy-saving effect than IE2, suitable for high energy consumption scenarios.

Structural design and installation

(1) Core structural components

Key characteristics of component materials/specifications

Machine base and end cap cast iron anti-corrosion grade C3 (medium), paint color Munsell Blue 8B4.5/3.25

Stator winding copper F-class insulation, B-class temperature rise, corona resistant design

Rotor die cast aluminum half key balance, stable operation

Deep groove ball bearing (standard) with D-end axial locking, optional cylindrical roller bearing for machine base size ≥ 132 (variable code 037)

Junction box cast iron IP55 protection, built-in grounding bolt, supports multi-directional cable entry

Fan glass fiber reinforced polypropylene (standard), optional metal fan for high-speed scenarios (variable code 068)

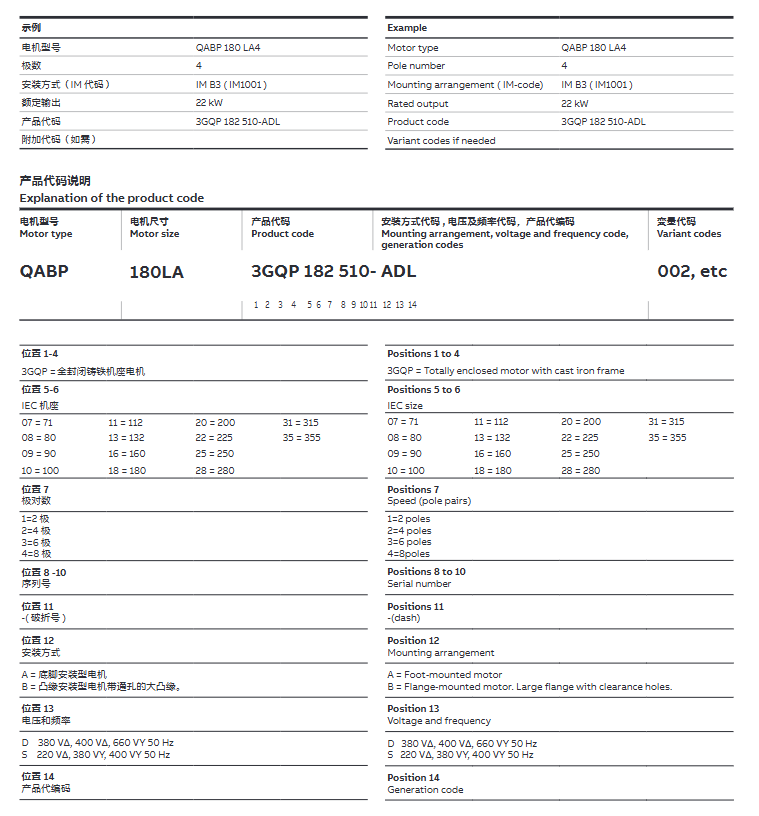

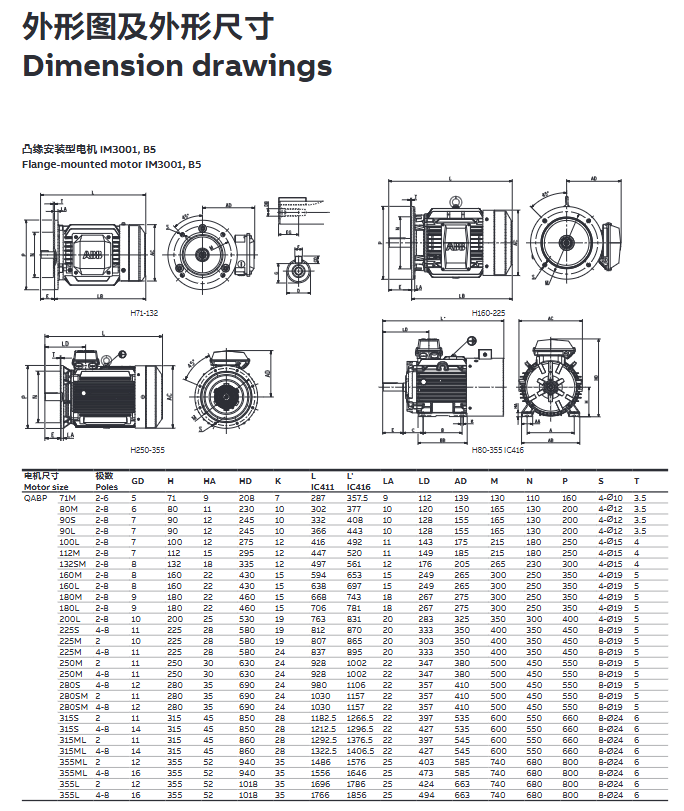

(2) Installation method and size

Installation type: Supports 4 types of core installation methods, which can be customized through variable code extension:

Foot installation (IM B3/IM1001): suitable for most general scenarios

Flange installation (IM B5/IM3001, IM B14/IM3601): Small flange/large flange optional

Foot+flange installation (IM B34/IM2101, IM B35/IM2001): combines the advantages of two types of installation

Key dimensions: Machine base size 71-355mm corresponds to shaft extension length of 30-210mm, flange aperture of 4- Ø 10~8- Ø 24mm (randomly increased seat size).

Function configuration and variable code

(1) Core functions

Variable frequency speed regulation: supports constant torque below 50Hz and constant power speed regulation above 50Hz, with a wide speed regulation range and smooth torque without crawling phenomenon.

Temperature compensation: Automatic temperature compensation is achieved through Pt100/Pt1000 sensors to ensure measurement accuracy at different temperatures.

Protection function: Equipped with overload and winding overheating protection (optional PTC/bimetallic temperature switch), bearing current protection (ceramic plated shaft/insulated bearing).

(2) Main optional configurations

Configuration type represents the applicable scenario of the product/code

Emergency braking scenarios required for lifting, conveying, etc. for brakes UHT B (H71-225) and INTORQ BFK458 (H71-225)

Encoder Leine&Linde RHI503 (H80-132), HUBNER HOG10 (H160-355) high-precision speed feedback scene

Lubricating grease is resistant to low temperatures (variable code 039), high temperatures (variable code 040), and extreme temperature environments (-40 ℃~80 ℃+)

Heating strip 100-120V (450), 200-240V (451) low temperature moisture-proof scene

EMC Protection EMC Cable Sealing Tube (Variable Code 704) Electromagnetic Interference Sensitive Scene

(3) Variable code description

The variable code covers more than 10 types of customized requirements, including management, balancing, bearings and lubrication, cooling systems, protection, installation, testing, etc., most of which are applicable to IE2/IE3 motors at the same time.

Common code examples: Extended warranty (865=1 year, 530=2 years), IP65 protection (158), independent cooling (183), insulated bearings (701).

Application scenarios and adaptation industries

Applicable industries: papermaking, metallurgy, mining, lifting, wind power yaw, rubber and plastic, textile, printing and packaging, food and beverage, chemical industry, water treatment, HVAC, etc.

Typical supporting equipment: industrial machinery that requires variable frequency speed regulation, such as pumps, fans, compressors, conveyors, machine tools, and mixing equipment.

Leave a comment

Your email address will not be published. Required fields are marked *