MOBY I is a high-performance radio frequency identification system (order number 6GT2 097-4BA00-0EA2) released by Siemens in 2007. Its core is used for contactless material flow and production process optimization in industrial scenarios. It consists of a mobile data storage (MDS), a read-write device (SLG), an interface module (ASM), and supporting accessories. It supports 8-32 kbytes storage capacity, 0-1000 mm read-write distance, -25 ° C to 200 ° C (cyclic) working temperature, and can be connected to SIMATIC S5/S7, PC and other devices as well as PROFIBUS protocol. The document covers system configuration, installation specifications, component parameters, fault troubleshooting, and other content in detail. Only qualified professionals are allowed to operate it to ensure safety and equipment. Compatibility.

Core Component Details

2.1 Mobile Data Storage (MDS)

Comparison of core parameters

MDS model storage capacity, working temperature protection level, read-write distance (max), special characteristics

MDS 401 8 kbytes (FRAM) -25~+85 ° C IP67 10 mm circular design, suitable for small carriers

MDS 404 8 kbytes (FRAM) -25~+85 ° C IP68 25 mm square design, compatible with metal installation

MDS 507 32 kbytes (RAM) -25~+70 ° C IP65 1000 mm long-distance transmission, battery powered

MDS 514 32 kbytes (FRAM) -25~+85 ° C IP68 90 mm high storage capacity, resistant to harsh environments

MDS 439E 8 kbytes (EEPROM) cyclic 200 ° C IP68 125 mm high temperature resistance, suitable for painting and drying scenarios

Common characteristics

Storage type: Supports RAM (requires battery), FRAM (no battery), EEPROM (high stability)

Data retention: FRAM/EEPROM data is retained for 10 years, RAM relies on battery backup

Chemical resistance: The shell material (polyamide 12, PPS) is resistant to industrial chemicals such as oil, grease, acid and alkali

2.2 Read Write Devices (SLG)

Comparison of core parameters

SLG model read-write distance range, working temperature protection level, transmission window size (L × W), applicable scenarios

SLG 40 2~8 mm -25~+70 ° C IP65 diameter 18 mm short distance precise recognition, small assembly line

SLG 42 0~55 mm -25~+70 ° C IP65 90 × 36 mm medium distance, dynamic transmission of moderate data volume

SLG 43 0~100 mm -25~+70 ° C IP65 140 × 60 mm medium to long distance, large transmission window

SLG 44 100~800 mm -25~+70 ° C IP63 1200 × 300 mm long distance, high-speed moving scene (up to 120 km/h)

SLG 41C 0~15 mm -25~+70 ° C IP67 30 × 8 mm compact, high protection, harsh environment

Common characteristics

Transmission frequency: power transmission 134 kHz, data transmission 1.81 MHz

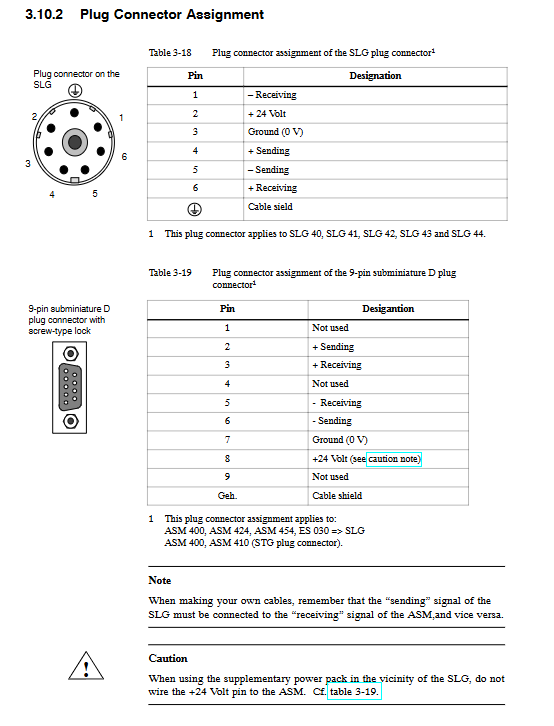

Interface standard: RS 422, transmission rate 19200 baud

Interference Suppression: Supports sensitivity adjustment for reception and adapts to industrial interference environments

2.3 Interface Module (ASM)

Core types and adaptation scenarios

ASM model docking interface supports SLG quantity protection level adaptation controller core functions

ASM 400/401 SIMATIC S5 bus 4 (parallel) IP00 SIMATIC S5-115U~155U basic control, supporting FB 250/230 function blocks

ASM 450/452 PROFIBUS DP/DPV1 2 (multiplex/pseudo parallel) IP67 various PLC/PC industrial bus docking, supporting file processors

ASM 470/475 SIMATIC S7 bus 2 (multiplex/parallel) IP20 SIMATIC S7-300/ET 200M high-speed data transmission, compatible with S7 system

ASM 424 RS 232/422 4 (parallel) IP40 PC/external controller serial port docking, supporting 3964R protocol

ASM 473 PROFIBUS DPV1 1 IP67 ET 200X distributed I/O scenario, high protection

2.4 Supporting Accessories

Software: MOBY Software (order number 6GT2 080-2AA10), including FB/FC function blocks, drivers, and diagnostic tools

Hardware:

Wide range power supply (6GT2 494-0AA00): 100~230V AC to 24V DC, output 2.2A

STG I handheld terminal (6GT2 003-0CA00): mobile read/write, debugging, supports Chinese and English menus

ES 030-K Collection Station (6AW5 451-3): Multi interface integration, compatible with barcode/MOBY systems

Connecting cable: shielded cable (6-core+shielded), maximum length 1000 m, core wire cross-section 0.07~1.5 mm ²

System configuration and installation specifications

3.1 Core Configuration Principles

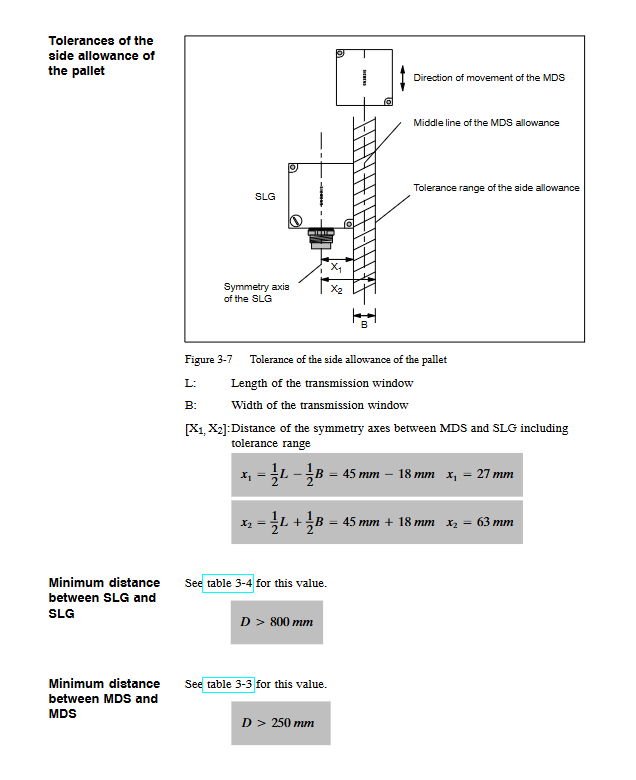

Transmission window: SLG generates induced alternating field, MDS needs to be within the effective field strength range (Sg is the limit distance), and dynamic transmission needs to meet the transmission cycle

T V ≥ t K (t K is the communication time)

Metal influence: Metal will reduce the transmission window, and a metal free area (minimum 10-80 mm from the edge of MDS/SLG to the metal) needs to be reserved, which can be isolated by plastic brackets (spacing 8-20 mm)

Distance requirement:

Minimum distance between SLGs: 50 mm (SLG 40)~6000 mm (SLG 44)

Minimum distance between MDS: 50 mm (SLG 40)~4000 mm (MDS 507)

3.2 Special Configuration Instructions

MDS 507+SLG 44 (long-distance combination):

ABTAST parameter (scan interval) needs to be configured to avoid the battery running out too quickly. It is recommended t ABTAST≤1.2 sec

The transmission window is divided into a startup area (MDS ready) and a processing area (data transmission), with an angle deviation of ≤ 45 °

MDS 439E (high-temperature resistant combination):

The cyclic working temperature is ≤ 200 ° C, and the heating cooling cycle needs to be controlled (such as heating at 200 ° C for 1 hour and then cooling for>2 hours)

When the temperature is greater than 85 ° C, the transmission window parameters need to be multiplied by an offset factor C (0.7~1.05)

3.3 EMC and Grounding Standards

Shielding requirement: Both ends of the cable should be grounded, and the shielding layer should be connected to the cabinet over a large area to avoid shielding interruption

Equipotential connection: equipotential line cross-section ≥ 10 mm ², reducing interference caused by potential difference

Cabinet layout: Power components and control components are separated (spacing ≥ 10 cm), and signal lines and power lines are laid in separate slots

Interference suppression: Coil type equipment requires the addition of a freewheeling diode/RC circuit, and a filter should be installed at the power inlet

Troubleshooting and compatibility

4.1 Common fault codes (core)

Error code (hex) fault type troubleshooting direction

01 There is an error in removing MDS from the transmission window. Check the position of MDS

04 MDS memory error initializing MDS, checking battery status

06 SLG field interference increases SLG spacing, check shielded cables

0E ECC error enabled ECC driver, reinitialize MDS

80 MDS battery low voltage replacement MDS battery

4.2 Compatibility Description

Alternative models: The document provides alternative models for discontinued MDS/SLG/ASM models (as of September 2004), such as MDS 114 replaced by MDS 404 and SLG 44-ZA07 replaced by SLG 44 (6GT2 001-0DA10-0AX0)

Version compatibility: New components (such as ASM 452) are compatible with old systems and require updating the GSD file configuration

Summary of Key Technical Indicators

Category key indicator numerical range

Storage capacity of 8~32 kbytes

Transmission read-write distance 0~1000 mm

Transmission rate ≥ 0.8 millisecond/byte

Environmental working temperature -25 ° C~200 ° C (cyclic)

Protection level IP20~IP68

Communication protocols PROFIBUS DP/DPV1, RS 232/422, 3964R

Transmission frequency 134 kHz (power), 1.81 MHz (data)

Leave a comment

Your email address will not be published. Required fields are marked *