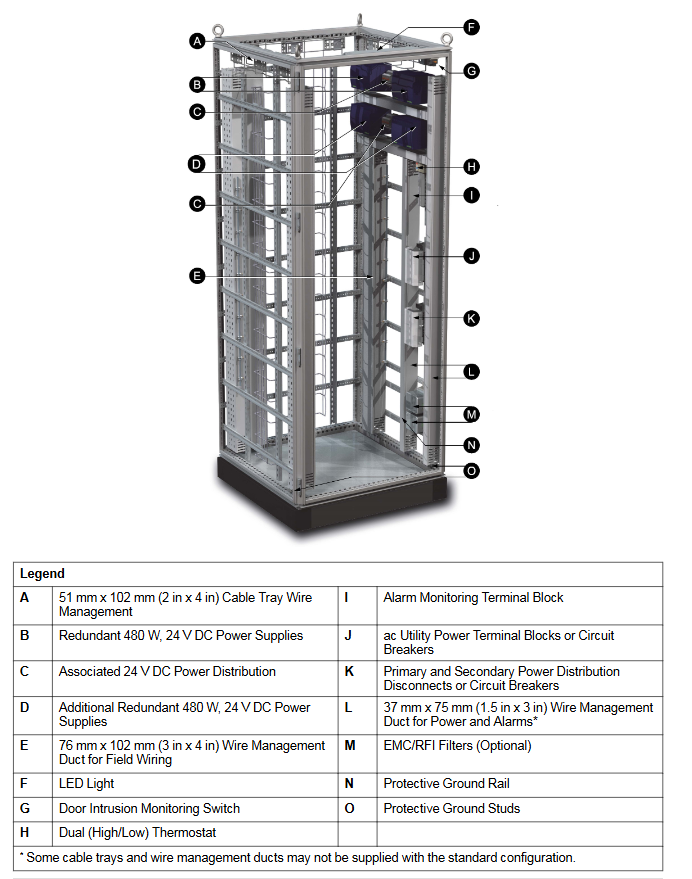

The G66 Triconex Tricon terminal housing is an industrial housing designed specifically for Triconex terminal equipment and users under the Foxboro brand of Schneider Electric. It supports forward/forward/backward bidirectional access and is available in two types: ventilated (IP 43/55) and sealed (IP 55/66). It is suitable for general or harsh environments and can be configured with up to 5 1800mm vertical DIN rails (bus rail space 9.0m). It can be optionally equipped with 480W or 960W redundant 24V DC power supply, supports bottom cable access (top access is not recommended), has dual grounding design, optional EMC compatible version, and door intrusion monitoring functions. It can be spliced and installed with other Triconex housings and is widely used in industrial control signal scenarios. Grouping and terminal connection.

Product Overview

Core positioning: A terminal housing designed specifically for industrial control scenarios, used for the installation and signal grouping of Triconex terminal equipment, especially suitable for wall mounted scenarios that only require forward access, and can be used in conjunction with G60, G62/G72 series housings.

Brand and Compliance: Foxboro brand products under Schneider Electric comply with UL/UL-C, CE certification, and EN 60529 protection standards. The EMC compatible version can meet specific regional electromagnetic compatibility requirements.

Installation flexibility: Floor standing independent installation, supports splicing with other Triconex shells through third-party kits, maximizes the use of floor space; Optional 100mm (4in) base for a total height of 2160mm (85.0in).

Core configuration and structure

Category key configuration detailed parameters

Type of enclosure: ventilated IP 43/55 protection, suitable for ordinary environments; Optional top/door mounted dual fans (120V/240V AC), top mounted fans have high cooling efficiency and low noise, while door mounted fans support top cable connection

Sealed IP 55/66 protection, suitable for harsh environments (IP 66 anti airborne pollutants), fanless design, heat dissipation through surface heat conduction of the housing

The terminal installation of the rail system can have up to 5 1800mm (72in) vertical DIN rails, with a total linear space of 9.0m (29.5ft). Install 1 pair each on the left, rear, and right walls

1 vertical DIN rail dedicated to the installation of power distribution equipment

Wiring design cable connection standard bottom connection, users can modify it to upper and lower dual connection (need to configure cable lights themselves and maintain protection level)

76mm × 102mm (3in × 4in) standard trunking configuration, supporting PVC/non PVC materials, optional signal isolation baffle to achieve adjacent trunking isolation

The safety protection door body is designed with a comfortable handle, button/key lock, and supports the modification of left and right door opening directions (default left opening)

The monitoring function includes optional door intrusion monitoring switches (1 per door, pre wired to the alarm terminal) and dual thermostats (high and low temperature alarm, range -0~60 ℃)

Power and grounding system

power configuration

Optional redundant 24V DC field power supply: 480W (P0923VD) or 960W specifications, supporting installation of 2 or 4 sets of field I/O power modules

Power access: The main power supply includes isolation switch terminals or 10A D-type bipolar circuit breakers, and optional EMC/RFI line filters

Distribution function: 24V DC power supply matching distribution terminal block, can supply power to up to 10 Triconex terminal devices, each port includes a maintainable isolation switch

Grounding design

Main grounding: 2 M8 protective grounding bolts (1 on each side of the housing), supporting dedicated grounding during splicing

Auxiliary grounding: 1 isolation protection grounding rail, which can be used for grounding the cable shielding layer

Structural grounding: All structural components of the shell are integrated with grounding, in compliance with industry electrical standards. The front door is connected to the frame through a 4mm ² (11ga) grounding strap

Technical parameter details

Specific indicators for parameter categories

Environmental parameters Operating temperature: Ventilation type -20~60 ℃ (average 750W/maximum 1000W load); Sealed type -20~55 ℃ (average 400W/maximum 500W load)

Storage temperature: -40~70 ℃ (-40~158 ° F)

Relative humidity: 5%~95% (no condensation)

Maximum weight of physical parameters: Ventilation type fully equipped 261kg (575lb); Side panel weight 8kg (18lb)

Shell dimensions: width 800mm x height 2000mm x depth 800mm (including base rear height 2160mm)

Material: 2.0mm (14ga) steel plate for frame/door panel; Side/top plate 1.5mm (16ga) steel plate; Surface coating RAL 7035 (light gray) textured paint

Acoustics and noise protection level: Top mounted fan 61dB (A) @ 1m, 58dB (A) @ 3m; Door mounted fan 64dB (A) @ 1m, 62dB (A) @ 3m; Sealed type with no additional noise

Protection level: Ventilation type IP 43/55; Sealed IP 55/66 (compliant with NEMA 12/4 standard)

Key points for installation and maintenance

Installation requirements: Must be fixed with bolts (to avoid tipping), refer to “Enclosures and Mounting Structures – Site Planning and Installation User’s Guide (B0700AS)”

Cable management: Equipped with cable ties for organizing Triconex terminal cables. Users need to provide their own cable glands and ensure that the protection level does not decrease after opening

Configuration customization: Users can order a version without power distribution terminal blocks according to regional electrical specifications, and configure the power connection themselves

Related documents: Supporting documents include G60/G62/G72 shell instruction manual (PSS 41H-2G60/62), Tricone system installation guide (9791007-XXX), etc

Leave a comment

Your email address will not be published. Required fields are marked *