MOVITRAC ® The B frequency converter is a drive control device launched by SEW-EURODRIVE, suitable for various motors. It complies with multiple international standards such as CE and UL, and provides various specifications from 0XS/0S/0L to 4/5. It is compatible with 230V (1-phase/3-phase) and 400/500V (3-phase) power supplies, with a power coverage of 0.25kW~75kW. The device supports multiple operation modes such as V/f and VFC, and can be operated through the FBG11B/DBG60B control panel MOVITOOLS ® MotionStudio software or external terminals are used for debugging and operation, with comprehensive safety protection, fault diagnosis, and data communication functions. It can be flexibly expanded with options such as FSC11B communication module and FIO11B analog module, and is widely used for motor drive control in scenarios such as pumps, fans, and industrial machinery.

Product Overview

Core positioning: A variable frequency drive control device designed specifically for industrial motors, supporting SEW and non SEW motors, providing flexible control and expansion capabilities

Compliance certification: Complies with low voltage standards (2006/95/EC), EMC standards (2004/108/EC), EN 61800-5-1 and other standards, and has passed multiple international certifications such as CE, UL, CSA, etc

Core advantages: complete specifications, diverse operation modes, flexible debugging methods, complete security protection, strong scalability, global service support

Equipment specifications and basic parameters

Specification series: Suitable for power supply, power range, key dimensional features (width x height x depth, example), weight range

0XS/0S/0L 230V (1-phase/3-phase), 400/500V (3-phase) 0.25kW~4.0kW 0XS: 54.5 × 185 × 163.5mm 1.3kg~2.2kg

1/2S/2 230V (3-phase), 400/500V (3-phase) 3.7kW~15kW 1:105 × 315 × 173mm 3.5kg~6.6kg

3 230V (3-phase), 400/500V (3-phase) 11kW~30kW 200 × 465 × 251mm 15kg

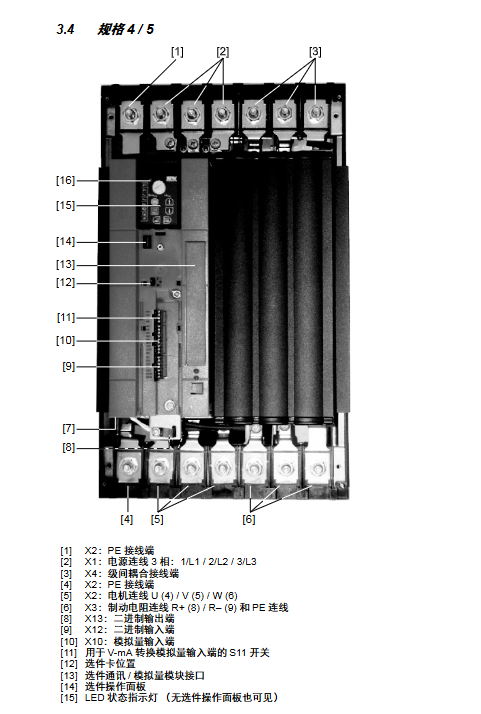

4/5 400/500V (3-phase) 37kW~75kW 4:280 × 522 × 250mm 27kg~35kg

Core functions and operating modes

(1) Classification of operating modes

Core characteristics of applicable scenarios for operating modes

V/f characteristic curve for ordinary loads, no special dynamic requirements, simple scene structure, high stability

The scenario where V/f+DC braking requires rapid shutdown has fast braking response and reduces downtime

VFC has high torque, low-speed operation, and precise slip compensation requirements. It has good dynamic performance and precise slip compensation

VFC+lifting device is suitable for lifting load characteristics of lifting equipment (such as cranes), with high safety redundancy

VFC+Fast Start: Industrial machinery that requires fast start response can start quickly and meet high-frequency start stop requirements

(2) Debugging and operation methods

Applicable scenarios for operation mode tools/carrier core functions

FBG11B panel operation includes parameter setting, fault reset, data copying, manual speed regulation, on-site quick debugging, and simple operation

DBG60B panel operation supports multiple languages, parameter group copying, user menu customization for complex parameter configuration, and batch debugging of multiple devices

Software operation MOVITOOLS ® MotionStudio offers visual debugging, parameter monitoring, data backup, batch configuration, remote debugging on the computer, and complex system integration

External control binary/analog terminal external signal triggering, fixed speed control, remote enabling industrial control system linkage (such as PLC)

Extended Control MBG11A Rated Value Regulator Multi device Speed Synchronization, Precise Rated Value Setting Multi motor Linkage Scenario

(3) Security and protection functions

Electrical protection: overcurrent (F-01), ground fault (F-03), intermediate circuit overvoltage (F-07), power phase fault (F-06)

Thermal protection: frequency converter thermal overload (F-11), motor winding temperature monitoring (TF/TH sensor)

Operation protection: speed monitoring (F-08), ramp timeout (F-34), equipment load overload (F-44)

Safety mechanism: Controller prohibition, safety stop, braking enable control, in compliance with EN 61800-5-1 safety standard

Option Expansion and Communication

(1) Core Options

Option Model Type Core Function Adaptation Scenarios

FSC11B communication module supports RS-485, SBus (CANopen), centralized data collection and remote control for multi device networking

FIO11B analog module extends analog input/output, supporting multiple analog signal interaction scenarios with -10~+10V voltage and 4~20mA current

MBG11A rated regulator for multi device speed synchronization control, supporting RS-485 communication pipeline, linkage machinery and other multi motor scenarios

FKE12B/FKE13B EMC module enhances electromagnetic compatibility and reduces interference in complex industrial environments

HD series output choke coil limits radiation interference and protects motor cables for long-distance motor cable connection scenarios

(2) Communication parameters

Communication protocols: Modbus, MOVILINK ®、 CANopen

RS-485 baud rate: 1200~19200bps (RS-232), 1200~38400bps (RS-485)

SBus baud rate: 125/250/500/1000kBaud, supports up to 64 bus devices

Data transmission: Supports bidirectional transmission of measurement values, parameter status, fault information, and control instructions

Fault diagnosis and maintenance

(1) Fault handling mechanism

Fault response type triggers scenario handling method

Immediately shut down serious faults (such as overcurrent and grounding faults), cut off the output stage, start braking, and manually reset

Stop general faults (such as high temperature, slope timeout) according to the set slope shutdown, and restart after the fault is reset

Timeout (warning) communication timeout (such as RS-485 timeout), quick shutdown, retain the ready to run signal, and automatically reset after communication is restored

(2) Maintenance points

Long term storage: power on for at least 5 minutes every 2 years; Failure to maintain as required requires graded voltage increase (230V equipment is divided into 3 levels: 170V → 200V → 240V)

Environmental requirements: working temperature -10 ℃~+60 ℃, storage temperature -25 ℃~+75 ℃, relative humidity 20%~95% (non condensing)

Cleaning and maintenance: Regularly clean the dust on the heat sink, check the tightness of the terminal wiring, and avoid electromagnetic interference sources from approaching

Technical Parameters (General)

Parameter category specific specifications

Power supply voltage tolerance ± 10% (compliant with EN 50160)

Operating frequency range 0~600Hz

Current limit 150% IN (minimum 60 seconds)

Analog input 0~10V (impedance>200k Ω), 4~20mA (impedance 250 Ω), resolution 10 Bit

Binary input signal level+11~+30V (1), -3~+5V (0), response time 5ms

Binary output maximum load current 150mA (DO02), 50mA (DO03), short circuit protection

Cooling methods: self cooling (≤ 1.1kW), external cooling (≥ 1.5kW, fan startup threshold 45 ℃)

Leave a comment

Your email address will not be published. Required fields are marked *