Product Core Overview

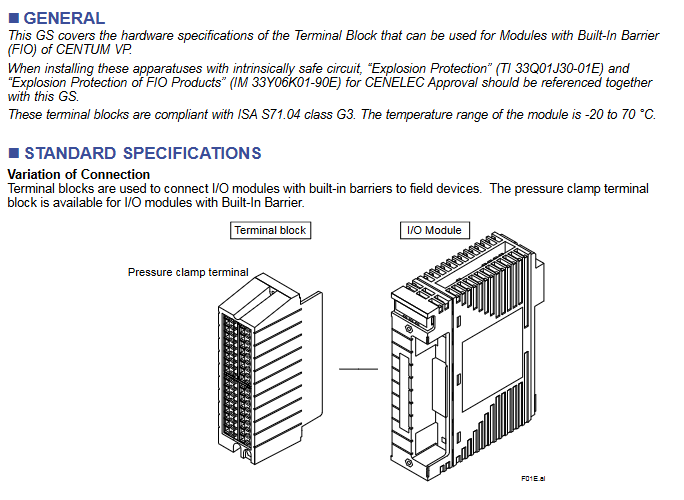

Product type: Pressure Clamp Terminal Block, a key intermediate component for signal transmission in industrial control systems

Applicable system: Designed specifically for the Yokogawa CENTUM VP control system, only compatible with FIO modules with built-in In Barrier in this system

Core function: To achieve stable circuit connection between I/O modules with built-in barriers and field devices, playing a role in signal conversion, fixed wiring, and ensuring transmission reliability. It is widely used in signal acquisition and control scenarios of industrial automation

Compliance standard: Compliant with ISA S71.04 class G3 standard, which specifies requirements for the environmental adaptability and safety performance of industrial process measurement and control equipment, ensuring stable operation of terminal blocks in complex industrial environments

Temperature adaptation range: -20 ℃ to 70 ℃, covering the temperature conditions of most industrial sites (such as factory workshops, control rooms, outdoor equipment areas, etc.), with strong environmental adaptability

Model system and core specifications

(1) Model classification logic

This series of terminal blocks is divided into two core series based on redundancy design. Each series is subdivided into specific models according to application types. The suffix code for all models is fixed at -0, with no other optional configurations. The classification logic is clear, making it easy for users to quickly select according to their actual needs

Single series: The model suffix is “S”, suitable for conventional industrial scenarios without redundancy requirements, with a simple structure and controllable cost

Dual Redundancy Series: The model suffix is “D” and is suitable for critical industrial scenarios that require extremely high system stability and reliability (such as core control links in industries such as chemical, power, and petroleum). The dual redundancy design ensures signal continuity in the event of a failure

(2) Detailed explanation of core specifications for all models

Model Application Type Channel Number Adaptation I/O Module Name Weight Core Adaptation Scenario

ATSA3S Analog Input (Single) 8-Point (8-Channel) ASI133 0.2 kg Analog Signal Acquisition in Conventional Scenarios, such as Input of Continuous Variables such as Temperature, Pressure, Flow, etc

ATSA3D analog input (Dual Redundant) 8-Point (8-channel) ASI133 analog signal acquisition under critical scenarios of 0.3 kg, ensuring uninterrupted signal acquisition, such as temperature acquisition of chemical reaction kettle

ATSS3S analog output (Single) 8-Point (8-channel) ASI533 0.2 kg analog signal output in conventional scenarios, such as controlling valve opening, adjusting pump speed, etc

ATSS3D analog output (Dual Redundant) 8-Point (8-channel) ASI533 analog signal output under critical scenarios of 0.3 kg, such as emergency stop control signal and core equipment speed control signal output

ATST4S thermocouple/mV (Single) 16 Point (16 channel) AST143 0.2 kg Temperature measurement signal or millivolt level small signal acquisition for thermocouples in conventional scenarios, such as furnace temperature and pipeline temperature monitoring

ATST4D thermocouple/mV (Dual Redundant) 16 Point (16 channel) AST143 high-precision temperature or small signal acquisition in critical scenarios of 0.3 kg, such as temperature monitoring in aerospace component processing

ATSR3S RTD/PAT (Single) 8-Point (8-Channel) ASR133 0.2 kg Thermal Resistance (RTD) temperature measurement or Potentiometer (POT) signal acquisition in conventional scenarios, such as equipment bearing temperature monitoring

ATSR3D RTD/PAT (Dual Redundancy) 8-Point (8-channel) ASR133 high-precision temperature or potentiometer signal acquisition in critical scenarios of 0.3 kg, such as temperature monitoring of nuclear power equipment

ATSB4S Digital Input (Single) 16 Point (16 Channel) ASD143 0.2 kg Digital Signal Input for Conventional Scenarios, such as Limit Switch Status and Equipment Operation Status (Run/Stop) Detection

ATSB4D Dual Redundant 16 Point ASD143 0.3 kg digital signal input for critical scenarios, such as emergency stop button signal and safety door switch status detection

ATSD3S digital output (Single) 8-Point (8-channel) ASD533 0.2 kg digital signal output in conventional scenarios, such as control indicator light on/off, relay on/off, small pump start/stop, etc

ATSD3D Digital Output (Dual Redundancy) 8-Point (8-channel) ASD533 Digital Signal Output for 0.3 kg Key Scenarios, such as Fire Alarm Signal Output, Emergency Cut off Valve Control Signal, etc

(3) Summary of Key Characteristics of Specifications

Channel number pattern:

8-channel models: a total of 8 types (4 single channel+4 dual redundant), covering analog input/output RTD/POT、 Four major categories of applications for digital output, meeting most conventional signal transmission needs

16 channel models: 4 types in total (2 single channel+2 dual redundant), only suitable for thermocouple/mV and digital input applications, suitable for scenarios requiring high-density signal acquisition, reducing the number of terminal block installations

Reason for weight difference: The single channel series is uniformly 0.2kg, and the dual redundancy series is uniformly 0.3kg. The weight increase is due to the additional hardware components such as circuits and wiring terminals required for the dual redundancy design, ensuring the implementation of redundancy functions

Module adaptation uniqueness: Each terminal block model corresponds to only one specific I/O module and cannot be mixed across models to avoid signal transmission failures or equipment damage caused by module and terminal block incompatibility

External dimensions and installation compatibility

(1) Size specification classification

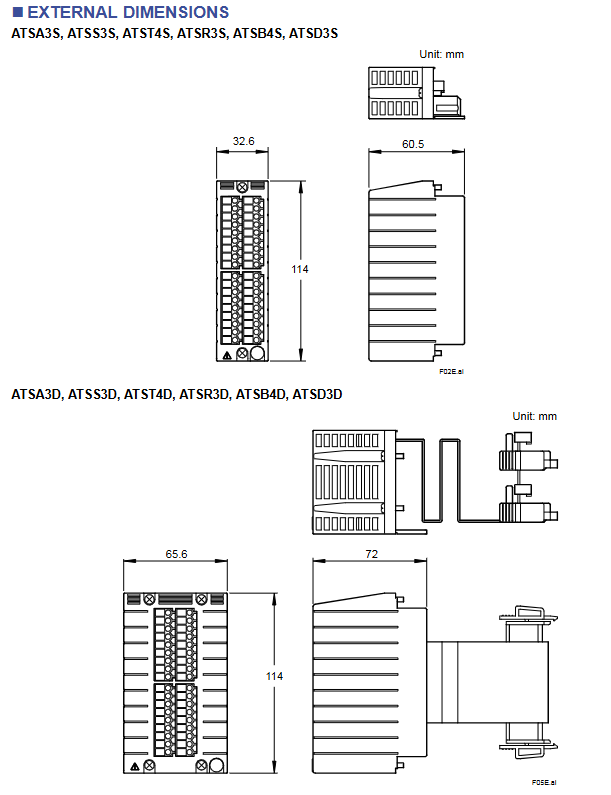

The size of the terminal block is directly related to the redundancy design, and all models within the same series have identical dimensions for standardized installation layout. The specific specifications are as follows:

Series types include model size parameters (unit: mm), reference drawings, installation and adaptation scenarios

Single channel series ATSA3S, ATSS3S, ATST4S, ATSR3S, ATSB4S, ATSD3S length x width x height: 32.6 x 60.5 x 114 F02E.ai is suitable for control cabinet layouts with limited installation space and no need for redundant design, and can be densely arranged

The dual redundant series ATSA3D, ATSS3D, ATST4D, ATSR3D, ATSB4D, ATSD3D length x width x height: 65.6 x 72 x 114 F05E.ai is suitable for the layout of control cabinets in critical control areas and requires a certain amount of installation space to ensure the heat dissipation and maintenance convenience of redundant components

(2) Dimensional design features

Height uniformity: All models have a height of 114mm, which facilitates the planning of installation positions according to the floor height inside the standard control cabinet and improves the cleanliness of the installation layout

Width differentiation: The width of the dual redundant series (72mm) is greater than that of the single channel series (60.5mm), and the length (65.6mm) is greater than that of the single channel series (32.6mm), adapting to the spatial requirements of its internal redundant structure

Standardized design: The dimensions comply with industrial equipment installation specifications and can seamlessly adapt to other supporting equipment of the Yokogawa CENTUM VP system (such as I/O modules, control cabinet rails, etc.), reducing installation difficulty

Model coding rules and ordering requirements

(1) Detailed explanation of coding rules

Explanation of optional/fixed values for the meaning of coding components

The prefix (such as ATSA, ATSS, etc.) application type identification ATSA (analog input), ATSS (analog output), ATST (thermocouple/mV), ATSR (RTD/PAT), ATSB (digital input), ATSD (digital output) prefix directly corresponds to the core application functions of the terminal block, making it easy to quickly identify

Intermediate numbers (such as 3S, 3D, 4S, 4D, etc.) indicate the number of channels and redundancy types. 3S (8 channels+single channel), 3D (8 channels+double redundancy), 4S (16 channels+single channel), 4D (16 channels+double redundancy) numbers “3” correspond to 8 channels, and “4” corresponds to 16 channels; The letters “S” and “D” distinguish redundant types

Suffix code configuration identifier -0 (fixed value) All models use a unified suffix code, with no additional optional configurations, simplifying the selection and ordering process

(2) Ordering requirements

Users need to specify the complete model (including suffix code) when placing an order, for example:

Conventional simulation input scenario: Order “ATSA3S-0”

Key scenario digital output: Order “ATSD3D-0”

Due to the fixed suffix code of -0, the core needs to confirm the model body composed of the prefix and the middle digit to ensure a complete match with the actual application type, channel number, and redundancy requirements.

Leave a comment

Your email address will not be published. Required fields are marked *