Core positioning and scope of application

Associated System: Designed specifically for MNS iS System Release 7.6 to guide communication and control integration of MConnect interfaces, supporting the integration of MNS iS as a fieldbus component into PLC or higher-level process control systems (PCS/DCS).

Target users: Control and application engineers who need to obtain MNS iS data and perform system integration, requiring users to have basic knowledge of fieldbus (such as PROFIBUS, Modbus).

Basic concepts and terminology definitions

The document provides explanations for over 30 core terms and abbreviations, covering technical terms, protocols, components, etc. The key terms are as follows:

Abbreviations/full names of terms/Chinese core explanation

Aspect Object ABBAspect is a computerized representation of real/virtual objects (such as pumps, services) that are described and structured through “attributes”

Standardized products that can be directly purchased and used in the COTS commercial spot product market

DTM Device Type Manager is a software module used to manage devices through fieldbus (such as PROFIBUS), supporting frameworks such as PactWare

GSD file device description file (German) PROFIBUS-DP/DP-V1 slave station hardware description file, used for device configuration

MCC motor control center is a switchgear used for motor control and protection, which is one of the core application scenarios of MNS iS

MODBUS RTU Modbus Remote Terminal Unit Protocol Fieldbus Communication Protocol, the core protocol for MConnect and circuit breaker communication

PNIO PROFINET IO is an open standard based on industrial Ethernet (IEC 61158/61784) used for distributed peripheral devices and automation

The SNTP Simple Network Time Protocol is a protocol that controls network time synchronization through Ethernet

The remaining terms (such as HMI, LVS, OPC, etc.) revolve around low-voltage switchgear, communication protocols, and system components, laying the foundation for subsequent technical content.

Hardware and software requirements

1. Hardware requirements

(1) MConnect hardware model and configuration

The MConnect hardware is based on the motherboard and is paired with different functional modules (analog input/output, digital input/output, PT100 temperature acquisition) to form 28 models. The core model identification rules are as follows (taking the 1TGE120071R series as an example):

Model ID Core Configuration Function Extension

1TGE120071R1000 motherboard only, no additional IO or temperature acquisition

1TGE120071R1001 motherboard+AIAO (Analog IO) supports analog signal input and output

1TGE120071R1100 motherboard+4DI2DO (24VDC digital IO) with 4 digital inputs and 2 digital outputs (24V DC)

1TGE120071R1500 motherboard+7DI0DO (110VAC-230VAC) 7-channel digital input, no digital output (110-230VAC AC)

1TGE120071R1600 motherboard+PT100-3CH supports 3-channel PT100 temperature acquisition (for control only, non protective function)

(2) Key hardware components

Control Condaptor: A specialized component (model 1TGE102069R0661) used to connect MConnect to MNS iS system, requiring address setting (cabinet number=circuit breaker cabinet number, level=1, position=1).

Communication interface: MConnect is connected to the circuit breaker through RS485 bus, with built-in bus bias and terminal resistance; An external 120 Ω (0.25W) terminal resistor is required on the circuit breaker side to ensure communication stability.

2. Software requirements

Basic version: MConnect requires a basic version of 7.6 or higher to fully support the functionality of MNS iS V7.6.

Auxiliary tools: Parameter settings need to be done in conjunction with MNavigate (Configuration and Management Tool), and some functions can be found in the MNavigate help documentation (such as hardware option usage).

Circuit breaker integration solution

The circuit breaker is the core component of the MNS iS cabinet, and MConnect achieves its monitoring and control through the following methods:

1. Supported circuit breakers and programmable release devices

Remarks on Programmable Release Devices (PR Units) Supported by Circuit Breaker Types

Emax PR122/P, PR123/P classic series, corresponding to PR12x series release

Emax X1, Tmax T7/T7M PR332/P, PR333/P upgrade series, corresponding to PR33x series release

Emax2 Ekip Touch, Ekip Hi Touch, Ekip G Touch, Ekip G Hi Touch intelligent series, supporting richer state and data collection

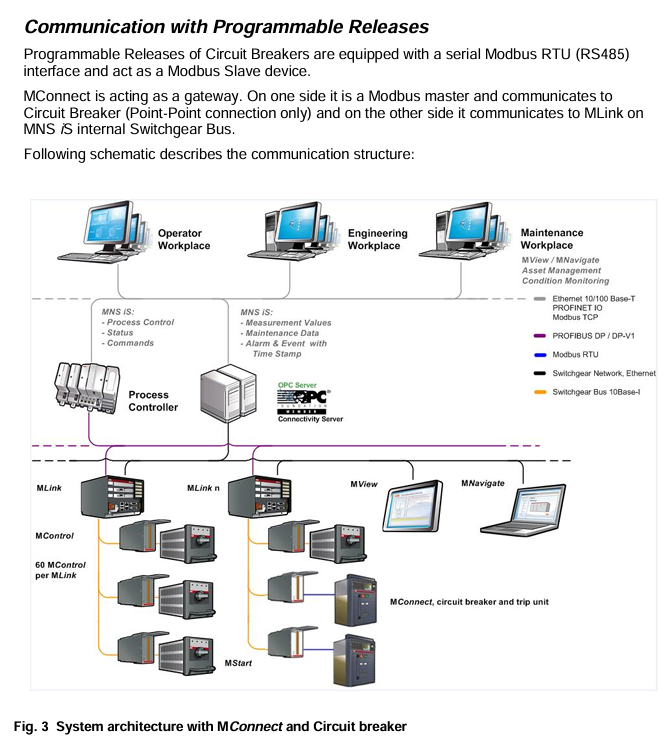

2. Communication architecture and connections

Communication role: MConnect serves as the Modbus RTU master and communicates point-to-point with the programmable release of the circuit breaker (Modbus slave) through RS485; At the same time, as a gateway, it communicates with MLink through the internal “Switchgear Bus” (10Base-T Ethernet) of MNS iS.

System limitation: Following the MNS iS design rules, each MLink can connect up to 60 devices (including MConnect and MControl), distributed in up to 7 cabinets.

Physical connection: The RS485 bus adopts a three wire system (A/W1, B/W2, shielded wire), and the terminal definitions of different circuit breakers are unified (for example, the A/B terminals of Emax and Emax2 are all W1/W2). Please refer to the document “1SDC007108G0201” for details.

3. Configure parameters

The Modbus interface parameters of MConnect need to be consistent with the circuit breaker release, and the parameter settings are as follows:

Parameter optional range, default value description

Slave Address 2-247 247 needs to be configured the same as the PR unit of the circuit breaker

Baudrate rate 9600/19200 bps 19200 bps communication rate, needs to match PR unit settings

Protocol parity check 1 stop bit, odd parity check 1 stop bit, no parity check 2 stop bit, no parity check 1 stop bit, even parity check 1 stop bit. The format of the data check and stop bit should match the PR unit

Attention: The MConnect main site address is fixed at 1 and cannot be modified by users; Only supports “point-to-point” communication and does not support multiple bus slaves.

Data and Command Interaction

The document provides a detailed definition of data collection (status, measurement values, alarm/trip information) and control commands for MConnect and two types of release devices (PR12x/PR33x, Ekip). The core content is as follows:

1. PR12x/PR33x series release

(1) Status data (32-bit unsigned number, Motorola byte order)

Device status bits: There are a total of 16 bits, with key bits meaning “open (Bit0), closed (Bit1), tripped (Bit2), undefined (Bit3), discharged (Bit4)”, and the remaining bits reserved (set to 0).

Extended Status Flag: Contains 8 types of flags, including State 2-9, covering alarm/trip (such as “any alarm” and “circuit breaker trip”), operating mode (local/remote), communication status (no communication on local bus), programming status (successful/failed programming), etc. Each type of flag is a 16 bit unsigned number (UWORD).

(2) Measurement value

Covering over 20 electrical parameters such as current, voltage, power, frequency, and energy, examples are as follows:

Measurement item data type unit invalid value explanation

L1 phase current (effective value) ULONG (unsigned long integer) A 0xffffffff current displays 0 when<minimum value, and displays maximum value when>maximum value

Line voltage V12 (effective value) UWORD-10 (10 times unsigned short integer) V 0xffff displays 0 when voltage<minimum value, and displays maximum value when voltage>maximum value

Total active power (signed) LONG_10 (10 times integer) kW 0x7ffffffff Display 0 when power<minimum value, display ± maximum value when out of range

Frequency UWORD_10 (10x unsigned short integer) Hz 0xffff: When the frequency is less than the minimum value, the minimum value is displayed, and when it is greater than the maximum value, the maximum value is displayed

Total active energy (signed) LONG kWh – cumulative energy value, supporting forward/reverse metering

(3) Alarm and trip information

By defining the STATE 4-6 (alarm) and STATE 8-9 (trip lock) flag bits, it covers over 30 abnormal scenarios such as “harmonic distortion exceeding 2.1”, “contact wear alarm”, “overvoltage trip”, “hardware fault trip”, etc. Each scenario corresponds to a specific bit (setting 1 indicates triggering).

2. Ekip series release (Emax2 specific)

(1) Status and measurement values

Status difference: The device status bit only retains “disconnected (Bit0), closed (Bit1), tripped (Bit2), undefined (Bit3)”, and the remaining bits are reserved; The extended state is divided into four categories: global state (such as circuit breaker closure/isolation), timing state (such as L/S/G timing triggering), trip state (such as overload trip), and warning/alarm state (such as sensor error), covering more detailed intelligent monitoring scenarios.

Measurement value expansion: Added parameters such as “RC current (external grounding current)”, “power factor (in kiloparts)”, “PT100 temperature”, etc., with data types compatible with PR12x/PR33x.

(2) Additional information collection

Support the full lifecycle data of circuit breakers, such as “Circuit Breaker Serial Number (16 bit ASCII)”, “Installation Date/Last Maintenance Date (seconds from December 31, 1999)”, “Operation Times (Opening Count)”, “Contact Wear Percentage (0-65000 corresponds to 0% -100%)”, etc., for easy maintenance and management.

3. Control commands (universal)

Only when the circuit breaker release is manually switched to “remote mode” (password required), the following commands can be sent through the MLink fieldbus:

Command function

CB Close Circuit Breaker Close

CB Open circuit breaker disconnected

CB Reset Circuit Breaker Reset

Trip Reset resets the trip records stored in the release device

Wink Toggle Command Circuit Breaker Identification (Tripper Display Flashing)

NOP no operation (no action)

4. Data validity (quality code)

Identify data validity through “QualityCode1” and “QualityCode2” (32-bit unsigned numbers):

Bit=0: Data is valid; Bit=1: Invalid data.

QualityCode1 covers measurement values (such as current, voltage, power), while QualityCode2 covers status indicators (such as alarm, trip) and equipment information (such as serial number, rated current).

Circuit breaker type decoding

The document provides decoding tables for two types of circuit breakers (TAB_CB.TYPE, TAB_CB.TYPE_33x), and specifies the specifications of the circuit breakers through a “numerical model” mapping. The example is as follows:

Decoding type, numerical circuit breaker model, numerical circuit breaker model

TAB_CB-TYPE (Emax series) 0 E1B800/3P 1 E1B800/4P

28 E2S800 / 3P 29 E2S800 / 4P

88 E4S4000 / 3P 89 E4S4000 / 4P

TAB_CB-TYPE_33x (Tmax/X1 series) 0 T7S800/3P 1 T7S800/4P

30 X1B800 / 3P 31 X1B800 / 4P

60 T7H1200 / 3P 61 T7H1200 / 4P

Note: “3P/4P” in the model indicates 3 poles/4 poles, and numbers (such as 800, 1200) indicate specifications related to rated current.

Leave a comment

Your email address will not be published. Required fields are marked *