Core Framework and Classification of Documents

The document is divided into three major modules based on media type, covering multiple bullet type components such as 1485A/C/F/G/K/P/R/T. Each module is subdivided into “cable connector auxiliary components” to form a complete DeviceNet network media solution:

Flat media system (pages 2-19): including KwikLink ™ Lite universal, heavy-duty flat cables and matching connectors, tap cables, etc;

Circular media system (pages 20-34): including thick and thin circular cables, sockets, terminal boxes, T-shaped interfaces, etc;

Auxiliary power circular dielectric system (pages 35-39): including auxiliary power cables, through board connectors, short-circuit plugs, etc.

Core component technical specifications

(1) KwikLink Flat Media System ™ Series)

Flat Cable

General/Heavy duty commonality: 4-core unshielded design, conductor material is tinned annealed copper, UL/CSA certification, working temperature -25~+75 ° C (heavy duty)/-10~+90 ° C (Lite type), voltage level 600V (auxiliary power type)/300V (signal type);

Differences: Heavy duty cables are UV resistant and oil resistant, suitable for outdoor/harsh environments (such as UL TC 600V 75 ° C sun resistance); Lite type is CL2/CM certified and suitable for indoor wiring (such as 19/21 AWG conductors).

Typical dimensions: Heavy duty cable width 19.3mm (0.76in), Lite type width 10.16mm (0.40in), conductor insulation layer made of colored PVC (red/white/blue/black).

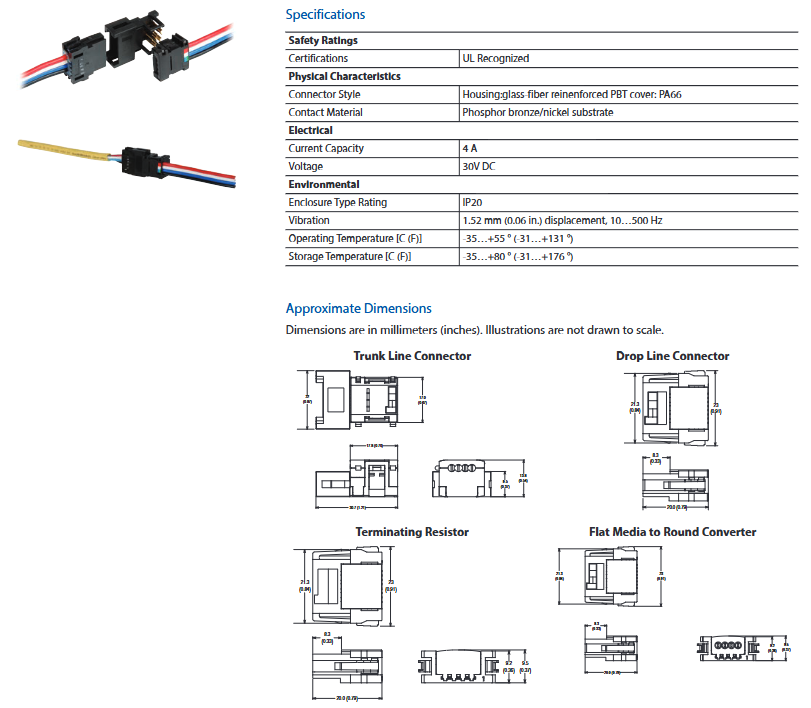

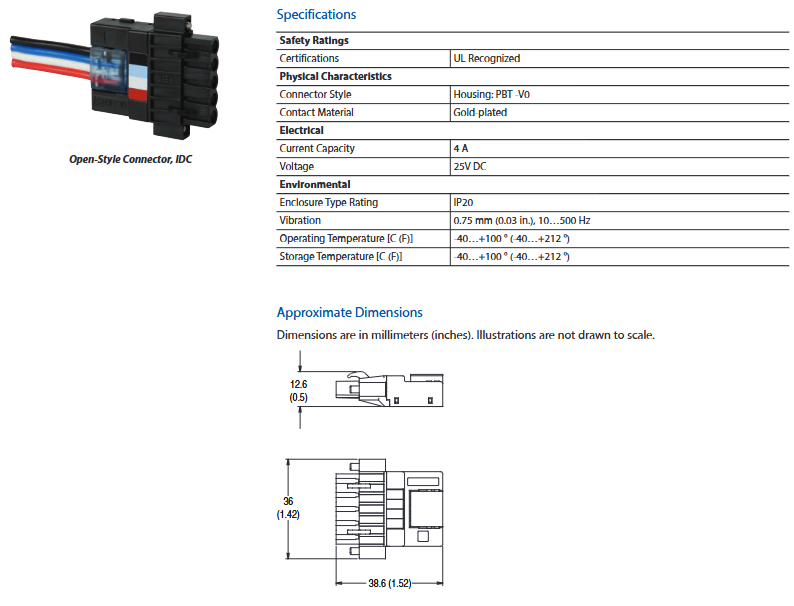

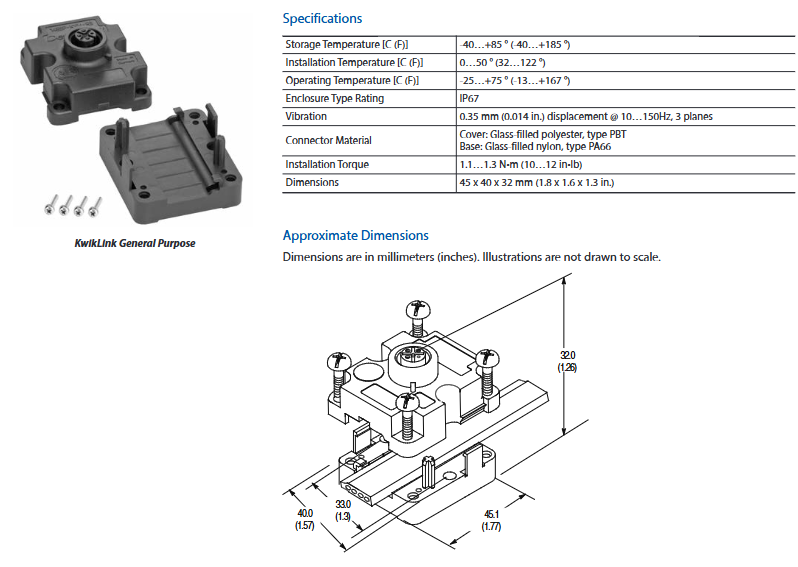

Flat media connector

Types: Trunk connectors, tap connectors, flat circular converters, IDC (Insulated Displacement Connectors), etc;

Core parameters: Contact material is phosphor bronze plated with nickel/gold, current capacity is 4A, voltage is 30V DC (Lite type)/250V (heavy-duty), protection level is IP20 (Lite type)/IP67 (heavy-duty, NEMA 6P/131200 psi flushing);

Environmental adaptability: Operating temperature -35~+55 ° C (Lite type)/-40~+100 ° C (heavy-duty), anti vibration (1.52mm displacement, 10~500Hz).

Auxiliary components

Tap changer cable: Oil resistant PUR shell, 22 AWG power wire+24 AWG signal wire, diameter 6mm, operating temperature -20~+80 ° C;

Terminal block IDC: gold-plated contacts, supporting 4A current, suitable for connecting flat cables to equipment terminals;

Splicing kit: Valox material shell, used for extending flat cable trunks, with a protection level of IP60 (unsealed)/IP67 (sealed).

(2) Circular medium system

round cable

Classification: Classified by thickness as “thick trunk cable” (12.2mm diameter, 15 AWG+18 AWG conductor pair+ground wire) and “thin trunk cable” (6.9mm diameter, 22 AWG+24 AWG conductor pair+ground wire);

Certification and level: UL Type PLTC/CM/TC-ER, CSA AWM I/II, oil resistant, UV resistant (thick cable), working temperature -20~+70 ° C;

Current capacity: Thick cable 8A (NEC 4A), thin cable 3A, voltage 300V (thick)/250V (thin).

Circular media connectors and interfaces

Receptacle: Mini/Micro, contact gold-plated brass, protection level IP67 (NEMA 6P), operating temperature -40~+80 ° C;

Terminal Chambers: Nylon shell, supports M12 threads, compatible with Mini/Micro connectors, resistant to impact (5g) and vibration (30-120Hz);

T-port: Made of PUR/TPE material, Mini type supports 8A current, Micro type supports 4A current, protection level IP67, suitable for branch wiring;

Bulkhead Pass thru: Nickel plated brass shell, Mini type 600V/8A, Micro type 250V/4A, used for cabinet through board sealing.

Network extension component

DeviceBox/DevicePort: 2/4/8 ports, made of black chemical resistant polymer material, with a protection level of IP67, supporting coarse/fine cable access, suitable for centralized wiring of multiple devices;

Terminator: Matching Mini/Micro connectors, 250V/4~8A, used for impedance matching of bus terminals;

Y-shaped adapter: made of nylon material, IP20 protection, 24V/8A, used for branch expansion of open wiring.

(3) Auxiliary power circular dielectric system

Specially designed to provide auxiliary power transmission for DeviceNet devices, the core components include:

Auxiliary power cable

Specification: 16 AWG (600V)/18/22 AWG (300V), yellow oil resistant PVC shell, UL STOOW/AWM certification, operating temperature -20~+105 ° C;

Current capacity: 16 AWG up to 10A, 18/22 AWG up to 4A, suitable for powering high-power equipment.

Specialized connector

Board connector: Mini type 600V/8A, protection level IP67, suitable for cabinet board insertion of auxiliary power cables;

Power T-type interface: 4-core Mini connector, 250V/4A, used for branch power supply of power supply main line;

Short circuit plug: made of red Santoprene material, 600V/10A, used for safe short circuit in case of equipment power failure.

Wiring specifications

4-core pin definitions: 1 (black, V -), 2 (white/blue, signal), 3 (red/brown, V+), 4 (green, signal);

Auxiliary power and signal cables need to be wired separately to avoid interference.

Common technical requirements and application scenarios

Certification and Compliance

All components are UL/CSA certified and partially comply with EN standards (such as IP67 protection), meeting industrial environmental safety requirements (such as NEC, IEC 529).

environmental adaptability

Temperature: Most components operate at temperatures ranging from -20 ° C to+70 ° C, while heavy-duty components can operate at temperatures as low as -40 ° C and as high as+105 ° C;

Protection: Outdoor/harsh environment components (such as heavy-duty flat cables, IP67 connectors) support oil resistance, UV resistance, and high-pressure flushing (1200 psi);

Mechanical performance: anti vibration (displacement of 10-500Hz), anti impact (5g), suitable for dynamic scenarios such as machine tools and automated production lines.

Wiring and installation

Conductor connection: IDC (Insulation Displacement Connection) is preferred to reduce wiring errors;

Shielding and grounding: Circular cables contain grounding wires, while flat cables are grounded at one end through cabinet grounding clamps to avoid electromagnetic interference;

Bending radius: All cables must meet a bending radius of “10 times the diameter” to prevent conductor breakage.

Core applications and selection suggestions

Application scenarios

Indoor automation equipment (such as PLC, sensors): Choose KwikLink ™ Lite flat media or thin circular media;

Outdoor/harsh environments (such as automotive production lines, food processing): Choose heavy-duty flat media or coarse circular media (IP67 protection, oil resistance);

High power equipment (such as servo motors): equipped with auxiliary power supply circular dielectric, powered by 16 AWG cable.

Key parameters for selection

Current: Select cables based on device power (such as thin cables for 3A and below, and thick cables for 8A and above);

Protection: Choose IP67 components for humid/dusty environments, and IP20/IP60 for dry environments;

Temperature: For low-temperature environments (such as cold storage), select -40 ° C low temperature resistant components, and for high-temperature environments (such as metallurgy), select+105 ° C high temperature resistant cables.

Leave a comment

Your email address will not be published. Required fields are marked *