Large-scale power converters and drives

must be reliable, fast and precise. That

calls for a control system with outstanding

performance, such as the AC 800PEC.

But why should the same controller not

cope with slow processes, too, such as

cooling circuits, monitoring and balance

of plant?

The AC 800PEC does it all: when it comes

to high-speed processes in an industrial

environment with all related ancillary

tasks, it is the ideal controller.

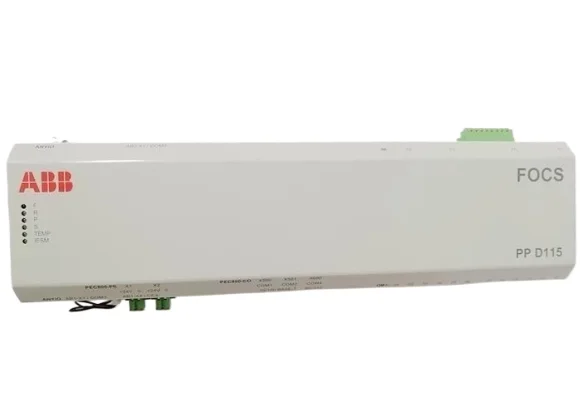

The AC 800PEC is ABBs high-end process

control system, and belongs to the Control IT

product line.

The AC 800PEC is the optimum solution

for combining

•the high-speed control requirements

of power electronics applications

•low-speed process control tasks

usually carried out by separate

PLC units.

The AC 800PEC controller is configured and

programmed using Control Builder M, ABB’s

well-established programming tool, and

MATLAB®/ Simulink® with Real-Time

Workshop®.

Key benefits

The AC 800PEC is a modular high-speed

control system. The modules are

arranged according

to the required I/O

configuration

and the process.

The AC 800PEC I/O

modules are

connected

via optional

high-speed

point-to-point

connections.

The AC 800PEC supports up to

36 bi-directional fiber-optic

PowerLinks.

Performance

The AC 800PEC excels with a very high

processing speed. It provides

•Very fast analog and digital process I/Os with

a typical cycle time of 25 µs

•Fast closed-loop control and regular process

logic implemented in one controller

•Low-speed I/Os with a typical cycle time of

10 ms

•Very fast analog/digital conversion and

nominal/actual value comparison, directly on

the peripheral I/O module.

Leave a comment

Your email address will not be published. Required fields are marked *