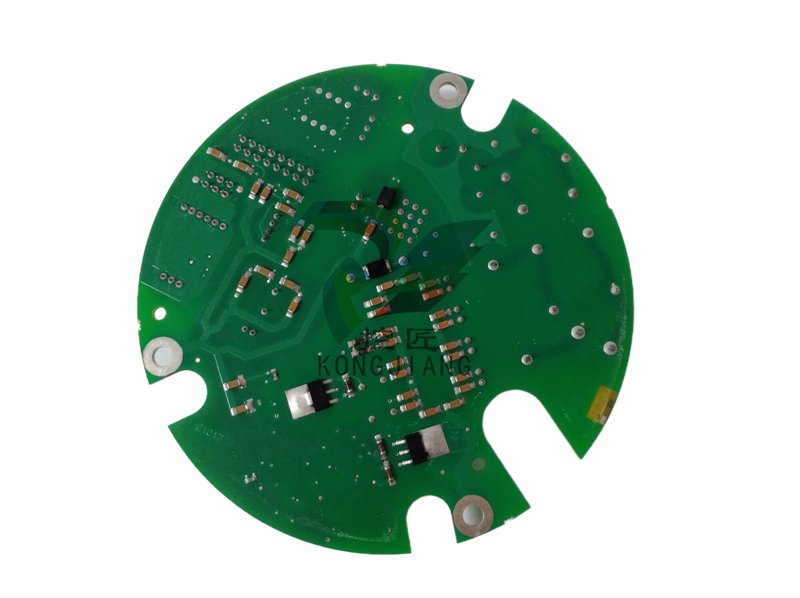

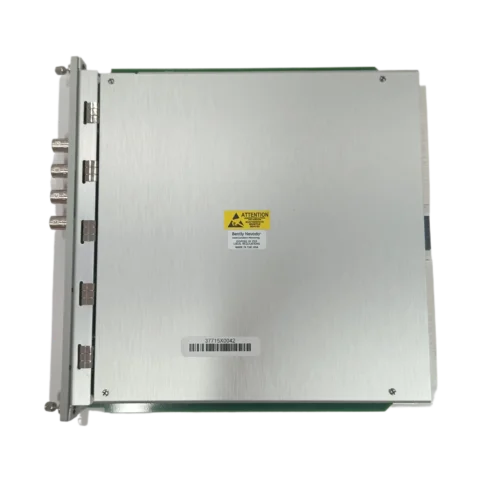

BENTLY Nevada 3300/16-15-01-03-00-00-00 Dual Channel Vibration Monitor Precision Engineering for Industrial Control Systems

BENTLY Nevada 3300/16-15-01-03-00-00-00 is a dual-channel vibration monitor designed for precise machinery diagnostics. It features advanced signal processing capabilities and robust construction to ensure reliability in demanding environments. This model operates effectively in temperatures ranging from -40°C to 70°C and supports multiple input types.

Ideal for rotating machinery, the 3300/16 is commonly used in power plants, oil and gas facilities, and manufacturing plants to detect imbalances, misalignments, and bearing failures. Its real-time monitoring allows for proactive maintenance, reducing downtime.

This model complements others in the BENTLY lineup, such as the 3500/20, 3500/45, and 3300/20. Compared to the 3500 series, the 3300/16 offers a more compact solution while retaining essential monitoring features. Unlike the 3500/40M, it doubles the channel count, making it suitable for applications requiring simultaneous monitoring of two machines.

The above parameters are for reference only. Please contact our technical team for precise selection.

Ideal for rotating machinery, the 3300/16 is commonly used in power plants, oil and gas facilities, and manufacturing plants to detect imbalances, misalignments, and bearing failures. Its real-time monitoring allows for proactive maintenance, reducing downtime.

This model complements others in the BENTLY lineup, such as the 3500/20, 3500/45, and 3300/20. Compared to the 3500 series, the 3300/16 offers a more compact solution while retaining essential monitoring features. Unlike the 3500/40M, it doubles the channel count, making it suitable for applications requiring simultaneous monitoring of two machines.

The above parameters are for reference only. Please contact our technical team for precise selection.

-1-480x480.png)

There are no reviews yet.